Thermit Welding Guide: Process & Equipment

Many industries rely on The Thermit welding process , even though it’s not as widely discussed as methods like MIG or TIG welding. This welding technique was initially developed for joining railroad tracks but has since found use in numerous applications requiring strong, permanent joints. Thermit welding involves a high-temperature exothermic reaction that melts metals, allowing them to bond seamlessly. It is a critical welding process for sectors where external power sources are either unavailable or impractical.

The importance of thermit welding extends far beyond its industrial roots. It has transformed the way we maintain infrastructures, ensuring that projects requiring robust and long-lasting joints—such as bridges, railway lines, and steel structures—remain stable for decades.

What is Thermit Welding?

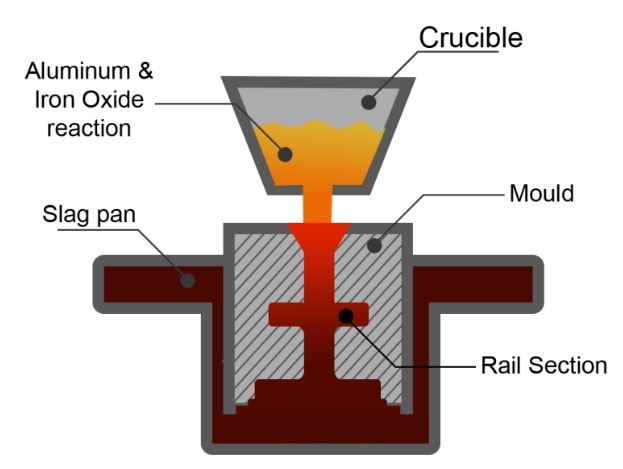

Thermit welding, also called thermite welding, is a unique process in which two metal parts are fused by the heat generated from a chemical reaction. This reaction occurs between aluminum powder and iron oxide, producing molten iron and aluminum oxide slag. The molten iron then fills the gap between the two metal parts, creating a fusion bond once it cools and solidifies.

This process stands out because it does not require electricity or external heat sources like other welding techniques. It relies entirely on the chemical reaction, which makes it particularly valuable in fieldwork where bringing electrical equipment is impractical or impossible. This is why thermit welding has become a go-to method in places like railway construction, where remote sections of track need to be joined.

How Thermit Welding Process

To better understand how thermit welding works, it’s essential to delve into the details of the thermite reaction. The process can be broken down into several critical steps:

- Preparation: First, the surfaces of the materials to be joined must be meticulously cleaned and aligned to ensure a smooth bond. Even small contaminants like dust or oil can interfere with the integrity of the weld.

- Setting the Mold: Once the materials are prepared, a refractory mold is placed around the area to be welded. This mold helps shape the molten iron, directing it into the space between the metal pieces.

- Igniting the Thermite: The thermite mixture, typically a combination of aluminum powder and iron oxide, is placed in a crucible. A magnesium strip or other ignition sources is used to start the reaction, producing an extremely high temperature—around 2,500°C (4,500°F).

- Pouring the Molten Iron: Once the reaction is complete, the molten iron is poured into the mold, where it fills the gap between the metal pieces. The slag (the byproduct of the reaction) floats to the top and is easily removed once the metal has cooled.

- Cooling and Finishing: After the molten iron solidifies, any excess material or slag is chipped away. The result is a smooth, seamless weld that is exceptionally strong.

This process allows thermit welding to create joints that can withstand heavy loads and harsh conditions, making it invaluable for large-scale infrastructure projects.

Types of Thermit Welding Proces

Thermit welding can be divided into two main types, each with its specific use cases and methods:

- Fusion Welding: This is the most common type of thermit welding. The molten metal generated by the thermite reaction flows between the materials being welded, filling the gaps and creating a solid joint without external pressure. This type of welding is typically used in applications where high-strength joints are required, such as railway track repairs.

- Pressure Welding: In contrast to fusion welding, pressure welding involves applying force to the materials being welded while the molten metal is cooling. This compresses the materials and creates a more compact bond. It is particularly useful in situations where maximum strength is required or where the materials being welded need additional structural integrity.

Both methods are used across various industries, but fusion welding is the most widely recognized due to its practicality and effectiveness in large-scale projects.

Key Equipment Used in Thermit Welding Process

Thermit welding is a specialized process that requires several key pieces of equipment, each essential for a successful weld. Let’s break them down:

- Thermite Materials: The core of thermit welding is the thermite itself, a mixture of aluminum powder and iron oxide. These materials react with each other to produce molten iron, which is the actual welding agent.

- Molds and Crucibles: The refractory molds are used to contain and direct the molten metal. These molds are made from materials that can withstand extreme temperatures without melting or breaking. The crucible is where the thermite reaction takes place before the molten iron is poured into the mold.

- Preheating Devices: Depending on the job, you may need to preheat the materials to ensure a stronger bond. Preheating helps to reduce thermal shock and improve the weld’s overall integrity.

- Personal Protective Equipment (PPE): Safety is a top priority in thermit welding, and appropriate PPE includes heat-resistant gloves, face shields, and flame-retardant clothing. The heat generated by the thermite reaction is intense, and safety gear is essential to protect the welder.

- Specialized Tools: Additional tools, like slag hammers, are used to remove excess slag after the weld has cooled. Other tools may include thermite igniters and pouring tongs.

Each of these pieces of equipment is vital for ensuring the weld is not only strong but also safe and precise.

Preparation Before Thermit Welding

Preparation is key in thermit welding, as it helps avoid issues during the welding process. Here’s a breakdown of the most critical preparation steps:

- Material Inspection and Cleaning: Before starting the weld, you must thoroughly inspect and clean the materials. Any rust, grease, or debris on the surface can weaken the weld. Metal parts should be smooth and free from any contaminants to ensure a proper bond.

- Safety Precautions: Due to the high temperatures involved, safety measures must be strictly followed. Ensure that the workspace is clear of flammable materials and that all safety equipment, such as fire extinguishers and first-aid kits, is readily accessible.

- Setting up the Welding Environment: A well-organized workspace is crucial. The mold must be positioned carefully, and all equipment should be within reach before beginning the welding process. In outdoor applications, such as railway welding, this may require additional planning to ensure a safe and stable work environment.

Thermit Welding Applications

Thermit welding is most commonly associated with large infrastructure projects. However, it is also used in a wide range of industries:

- Railway Track Welding: One of the most famous applications of thermit welding is in joining railway tracks. Since trains exert immense pressure on the tracks, a strong and reliable weld is essential. Thermit welding creates seamless joints that can handle the wear and tear of constant use.

- Steel Structure Maintenance: In the construction industry, thermit welding is often used to repair or maintain steel frameworks. For example, bridges or high-rise buildings may require thermit welding to ensure structural stability.

- Electrical Industry: Thermit welding is also used in electrical grids, particularly for joining conductors. The process creates highly conductive joints that ensure the reliable transmission of electricity.

- Automotive Industry: In some cases, thermit welding is used to repair heavy-duty parts in large vehicles, such as trucks or buses. The strong, durable welds ensure that these vehicles can continue to operate safely under heavy loads.

Advantages and Disadvantages of Thermit Welding

Thermit welding offers a number of advantages, but it also has its drawbacks.

Advantages:

- Strong and Durable Welds: The welds created by thermit welding are incredibly strong and durable, capable of withstanding heavy loads and harsh environmental conditions.

- No Need for External Power: Because it relies on a chemical reaction, thermit welding does not require electricity, making it ideal for remote locations.

- Versatile in Various Applications: Thermit welding can be used in a variety of industries, from railways to construction, making it a versatile solution for different welding needs.

Disadvantages:

- High Initial Setup Cost: The molds, crucibles, and thermite materials can be expensive, which increases the overall cost of the welding process.

- Time-Consuming: Thermit welding takes longer than other methods, which can be a disadvantage in situations where quick repairs are needed.

- Limited to Specific Materials: This process is mainly suited to ferrous metals like steel and iron. It is not ideal for non-ferrous metals like aluminum or copper.

Thermit Welding Safety Guidelines

Given the high temperatures and chemical reactions involved, safety is paramount when performing thermit welding. Some key safety guidelines include:

- Wear Appropriate PPE: Always wear protective gloves, goggles, and flame-resistant clothing to guard against the intense heat and sparks produced by the thermite reaction.

- Control the Work Area: Ensure that the work area is clear of flammable materials, and that proper ventilation is in place to manage any fumes or gases released during the process.

- Have Fire Extinguishers Ready: Due to the extreme heat of the process, always have fire safety equipment on hand in case of accidental fires or uncontrolled reactions.

- Follow Safety Standards: Comply with all safety regulations and standards, such as those set by OSHA or local authorities, to minimize the risk of injury or accidents.

FAQs

How does thermit welding differ from arc welding?

Unlike arc welding, thermit welding relies on a chemical reaction to generate heat, rather than electricity.

Can thermit welding be used on non-ferrous metals?

No, thermit welding is generally limited to ferrous metals like steel and iron.

What are the most common safety risks in thermit welding?

The main risks include burns from molten metal, fire hazards, and exposure to harmful fumes.

How long does a thermit weld last?

A well-executed thermit weld can last for decades, particularly in railway applications.

Is thermit welding cost-effective?

Yes, it is cost-effective for large-scale projects despite the high initial setup costs due to the longevity of the welds produced.

Conclusion

Thermit welding may be a specialized process, but its importance in industries like railways, construction, and electrical grids cannot be overstated. It creates exceptionally strong and durable welds that can withstand extreme conditions, making it an invaluable technique for large-scale projects. While it has some drawbacks, such as the high cost and time required, its benefits far outweigh the limitations when it comes to applications that require long-lasting and reliable welds.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders