Thermo-mechanically Affected Zone in Friction Stir Welding

Introduction

Friction Stir Welding (FSW) is a revolutionary solid-state joining process that has gained immense popularity in various industries due to its advantages over conventional welding methods. However, during the FSW process, a unique zone called the Thermo-mechanically Affected Zone (TMAZ) is formed. Understanding the formation, characteristics, and significance of the TMAZ is crucial for optimizing welding parameters and achieving superior weld quality.

Understanding Friction Stir Welding (FSW)

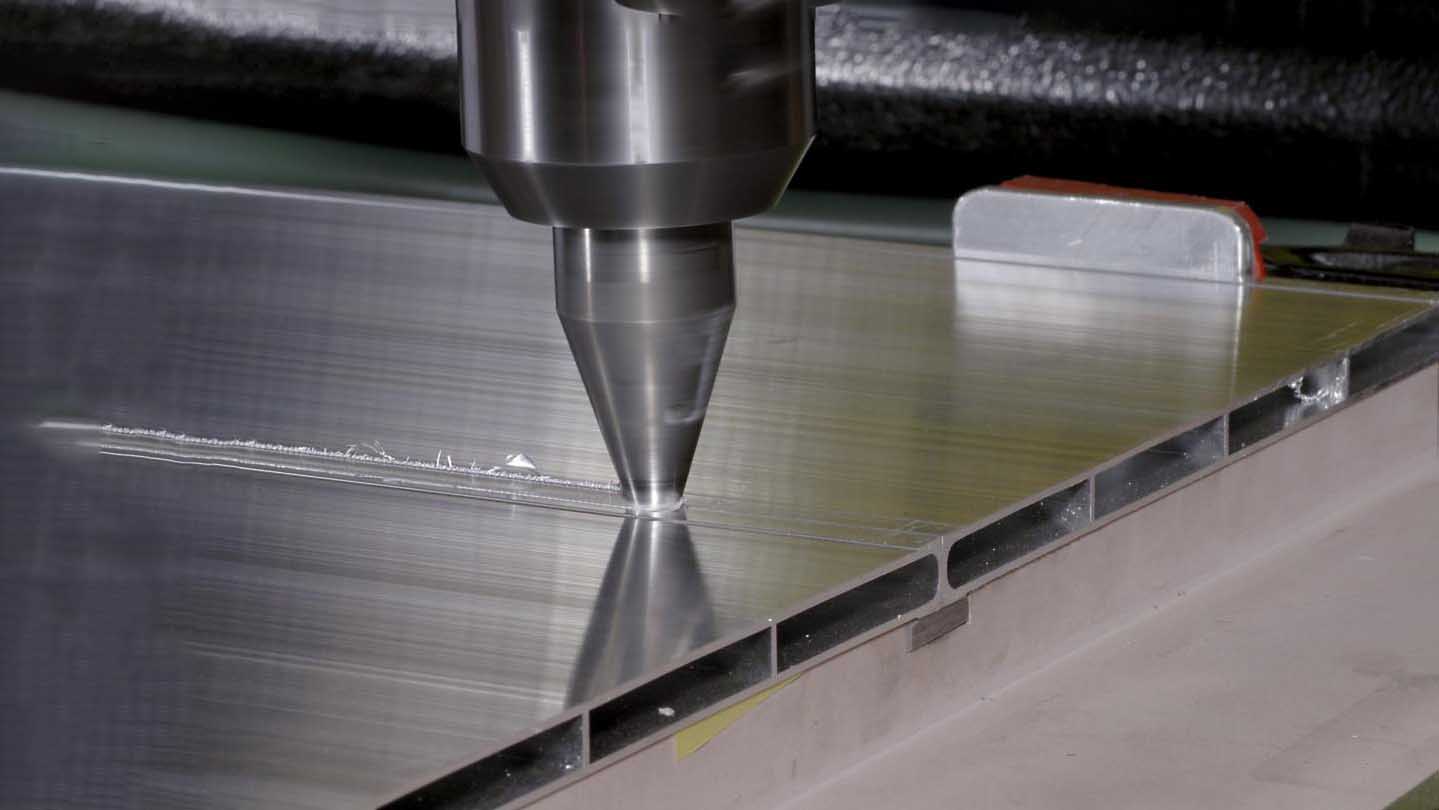

Friction Stir Welding is a solid-state welding technique invented in 1991 by Wayne Thomas at The Welding Institute (TWI). It involves joining two metal pieces without melting them. Instead, a rotating non-consumable tool with a specially designed profile is inserted between the plates, generating frictional heat that softens the material. The tool then stirs the softened material, forging it into a seamless joint.

Thermo-mechanically Affected Zone (TMAZ)

The Thermo-mechanically Affected Zone (TMAZ) is a critical region in the FSW process. It lies adjacent to the weld nugget and experiences substantial plastic deformation and temperature rise. The TMAZ can significantly influence the mechanical properties of the welded joint, making it an essential area to study.

Factors Influencing TMAZ Formation

Several factors influence the formation of the TMAZ during Friction Stir Welding:

1. Welding Parameters

The rotational speed of the tool, welding speed, axial force, and tool geometry all play a role in determining the extent of the TMAZ. Higher rotational and welding speeds generally result in a narrower TMAZ.

2. Material Properties

The properties of the base materials, such as their melting temperature, thermal conductivity, and mechanical properties, affect the size and characteristics of the TMAZ.

3. Tool Design

The shape, material, and shoulder diameter of the FSW tool affect the amount of heat generated and, consequently, the size of the TMAZ.

Microstructure Evolution in TMAZ

The microstructure of the TMAZ differs significantly from that of the base materials due to the thermo-mechanical processes involved. It typically consists of fine-grained recrystallized material with altered mechanical properties.

Mechanical Properties of TMAZ

The TMAZ exhibits unique mechanical properties compared to the base materials. It often has reduced hardness and strength due to grain refinement and potential precipitate dissolution.

Challenges and Mitigations

One of the primary challenges associated with the TMAZ is its lower strength, which may compromise the overall integrity of the weld joint. To mitigate this, optimizing welding parameters and post-weld heat treatments can be employed.

Advancements in Friction Stir Welding

Over the years, researchers and engineers have made significant advancements in FSW techniques. These include improved tool designs, intelligent control systems, and hybrid approaches with other welding methods.

Applications of Friction Stir Welding

FSW has found wide-ranging applications in industries such as aerospace, automotive, shipbuilding, and even in the manufacturing of pipelines and pressure vessels.

Future Prospects

The future of Friction Stir Welding and the TMAZ lies in further research on material-specific behaviors, advanced tooling, and automation. As the demand for lightweight and high-strength materials grows, FSW is likely to play an increasingly vital role.

FAQs

What is Friction Stir Welding?

Friction Stir Welding is a solid-state joining process that welds metals without melting them, using a rotating tool to generate frictional heat.

What is the Thermo-mechanically Affected Zone (TMAZ)?

TMAZ is the region surrounding the weld nugget in Friction Stir Welding that undergoes significant plastic deformation and temperature rise.

How does TMAZ affect weld quality?

The properties of the TMAZ can influence the overall strength and integrity of the weld joint.

What factors influence TMAZ formation?

Welding parameters, material properties, and tool design are key factors influencing TMAZ formation.

What are the future prospects of FSW?

The future of FSW lies in advanced research on material-specific behaviors, tooling, and automation to meet the demands of various industries.

Conclusion

Friction Stir Welding offers an innovative solution for joining metals, but its success relies on understanding and optimizing the Thermo-mechanically Affected Zone (TMAZ). Engineers and researchers must continue to explore the intricacies of the TMAZ to unlock the full potential of FSW in various industries.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders