Maximizing Quality: Comprehensive Guide Thermographic Testing for Welded Joints

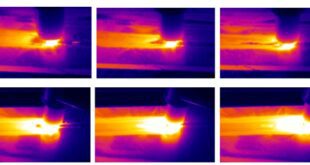

Thermographic Testing operates on the principle of detecting temperature variations. It utilizes an infrared camera to capture the heat patterns emitted by the surface of the welded joint. The underlying idea is simple: flaws or defects often generate distinct thermal signatures.

In the world of welding, ensuring the quality and integrity of welds is of paramount importance. Welds are the backbone of many structures, from buildings and bridges to pipelines and aircraft. Even the smallest defects in a weld can lead to catastrophic failures. This is where thermographic testing comes into play, offering a non-destructive and highly effective method for inspecting welds. In this article, we will delve into the world of thermographic testing in welding, exploring its principles, applications, advantages, and more.

Introduction

Welding is an indispensable process across various industries, but the quality of welds can be challenging to ascertain with the naked eye alone. This is where thermographic testing, also known as infrared thermography or thermal imaging, steps in. It utilizes the principles of heat detection to assess the integrity of welds and identify potential defects.

Understanding the Basics

Thermographic testing is based on the fact that different materials conduct heat differently. When a weld is created, it generates heat that dissipates throughout the welded components. Any irregularities in the weld, such as cracks or voids, can disrupt this heat flow, leading to temperature variations that are detectable through infrared imaging.

Why Weld Inspection Matters

The consequences of faulty welds can be catastrophic. For instance, in the aerospace industry, a compromised weld can jeopardize the safety of an entire aircraft. In construction, structural welds are the backbone of buildings and bridges, and any weakness in these welds can compromise the stability of the entire structure. Thus, ensuring the quality of welds through thermographic testing is not just a matter of compliance; it’s a matter of safety.

How Thermographic Testing Works

At its core, thermographic testing relies on the detection of heat anomalies. Here’s a brief overview of how the process works:

Infrared Imaging

Infrared cameras are the primary tools used in thermographic testing. These cameras can detect the infrared radiation emitted by objects, which is directly related to their temperature. In the context of welding, these cameras capture the temperature distribution across the welded area.

Heat Generation in Welding

During welding, heat is generated to melt the base metals and filler materials. This heat forms the basis for thermographic testing. As the weld cools down, any irregularities in the heat distribution become apparent through variations in temperature.

Detecting Anomalies through Temperature Variations

Thermographic testing identifies defects by analyzing the temperature patterns in the welded area. Irregularities such as cracks, porosity, or incomplete fusion result in localized temperature differences that are easily detectable through infrared imaging.

Applications of Thermographic Testing in Welding

Thermographic testing is a versatile technique that finds applications in a wide range of industries and welding processes. Here are some notable areas where it plays a crucial role:

Structural Welds

In construction and civil engineering, the integrity of structural welds is vital. Thermographic testing ensures that buildings, bridges, and other infrastructure projects meet stringent safety standards.

Aerospace Industry

Aircraft are subject to extreme conditions, making the quality of welds a matter of life and death. Thermographic testing is used to inspect critical welds in aircraft components.

Automotive Welds

In the automotive sector, thermographic testing is employed to assess the weld quality in vehicle components, enhancing both safety and performance.

Advantages of Thermographic Testing

The popularity of thermographic testing in welding can be attributed to several key advantages it offers:

Non-Destructive Nature

Unlike destructive testing methods that require the destruction of a sample, thermographic testing is non-destructive. It allows weld inspection without compromising the integrity of the welded structure.

Speed and Efficiency

Thermographic testing is a rapid process. Inspections can be completed quickly, reducing downtime and costs.

Detecting Hidden Defects

Thermography can reveal defects that are not visible to the naked eye. This early detection prevents potential disasters down the line.

Preparing for Thermographic Testing

Before initiating a thermographic inspection, certain preparations are essential to ensure accurate and reliable results. These include:

Surface Preparation

The surface of the weld must be clean and free of contaminants that could affect the accuracy of the inspection. Proper surface preparation is crucial.

Environmental Factors

Environmental conditions, such as ambient temperature and humidity, can impact the results of thermographic testing. It’s important to account for these factors during the inspection.

Choosing the Right Equipment

Selecting the appropriate thermographic equipment, including the type of camera and infrared lens, is critical to the success of the inspection. The choice should align with the specific requirements of the weld being tested.

Performing a Thermographic Inspection

Performing a thermographic inspection involves a series of steps to ensure accurate and reliable results. Here’s an overview of the process:

Setting Up the Camera

Proper camera setup is crucial for obtaining clear and meaningful thermographic images. This includes adjusting settings such as emissivity, focus, and distance.

Data Acquisition

During the inspection, the camera captures thermal data from the weld. This data serves as the basis for analysis and defect detection.

Data Analysis

The collected thermal data is analyzed to identify temperature variations that may indicate defects. Advanced software tools assist in this process, enhancing the accuracy of defect detection.

Interpreting Thermographic Images

Interpreting thermographic images requires a trained eye and an understanding of the specific weld being inspected. Here’s how the process works:

Identifying Defects

Thermographic images reveal temperature variations, but interpreting these variations as defects requires expertise. Common defects include cracks, lack of fusion, and porosity.

Quantifying Flaws

Not all temperature variations are indicative of defects. Quantifying flaws involves assessing the size and significance of temperature variations to determine if corrective action is necessary.

Reporting and Documentation

Accurate documentation of inspection results is essential for compliance and future reference. A comprehensive report should detail findings, including the location and severity of any defects.

Challenges and Limitations

While thermographic testing is a powerful tool, it does have its challenges and limitations. These include:

Surface Finish and Coatings

Irregular surface finishes and coatings can affect the accuracy of thermographic testing. Proper surface preparation is essential to overcome this limitation.

Complex Geometry

Welds in complex geometric configurations can pose challenges for thermographic inspection. Specialized techniques may be required to ensure thorough coverage.

Operator Skill

Interpreting thermographic images requires training and experience. Inexperienced operators may struggle to identify subtle defects accurately.

Comparison with Other Weld Inspection Methods

Thermographic testing is just one of several methods used to inspect welds. Let’s compare it to some of the other commonly employed techniques:

Radiographic Testing

Radiographic testing involves the use of X-rays or gamma rays to inspect welds. While highly effective in detecting internal defects, it can be time-consuming, costly, and exposes personnel to radiation.

Ultrasonic Testing

Ultrasonic testing utilizes high-frequency sound waves to detect flaws in welds. It is particularly useful for identifying internal defects but may require direct access to both sides of the weld.

Magnetic Particle Inspection

Magnetic particle inspection detects surface and near-surface defects by applying a magnetic field and magnetic particles to the weld. It is quick and cost-effective for surface inspections but may not reveal internal flaws.

Each of these methods has its strengths and weaknesses, making the choice of inspection method dependent on factors such as the type of weld, accessibility, and the desired level of detail.

Future Trends in Thermographic Testing

The field of thermographic testing is continuously evolving, driven by technological advancements and industry-specific needs. Here are some future trends to watch for:

Advancements in Infrared Technology

Infrared cameras are becoming more sophisticated, offering higher resolution and improved sensitivity. This enables thermographers to detect even smaller defects with greater precision.

Automation and AI Integration

Automation is simplifying the inspection process, with robots equipped with thermographic cameras being employed in various industries. Artificial intelligence (AI) is also being used to analyze thermal data, improving defect detection accuracy.

Industry-Specific Innovations

Different industries have unique welding challenges. As a result, thermographic testing solutions are being tailored to meet these specific needs. For example, specialized techniques are being developed for the inspection of pipelines, ship hulls, and nuclear components.

Cost Considerations

While thermographic testing offers numerous benefits, it’s essential to consider the associated costs. These costs can include:

Initial Investment

Investing in quality thermographic equipment, including cameras and software, can be significant. However, this initial expenditure is often justified by long-term savings through defect prevention and enhanced safety.

In addition to the initial equipment costs, there are ongoing expenses related to training, maintenance, and calibration.

Real-World Case Studies

To illustrate the practical applications of thermographic testing, let’s explore a couple of real-world case studies:

Successful Weld Inspections

In the construction of a new bridge, thermographic testing identified a hidden defect in a critical weld joint. The defect was promptly repaired, preventing a potential catastrophe once the bridge was in use.

Avoiding Costly Failures

In the manufacturing of pressure vessels, a routine thermographic inspection revealed a small crack near a welded seam. The vessel was taken out of service, and the weld was repaired, preventing a catastrophic failure that could have resulted in injury or loss of life.

Conclusion

Thermographic Testing has revolutionized the inspection of welded joints. Its non-destructive nature, speed, and efficiency make it a valuable asset across industries where structural integrity is paramount. From aerospace to energy, Thermographic Testing’s applications are wide-ranging, safeguarding both people and assets. For businesses and industries, investing in Thermographic Testing is not just a matter of quality control but a commitment to safety and reliability. Embrace this technology, and you’ll be taking a giant leap towards ensuring the longevity and dependability of your welded joints.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders