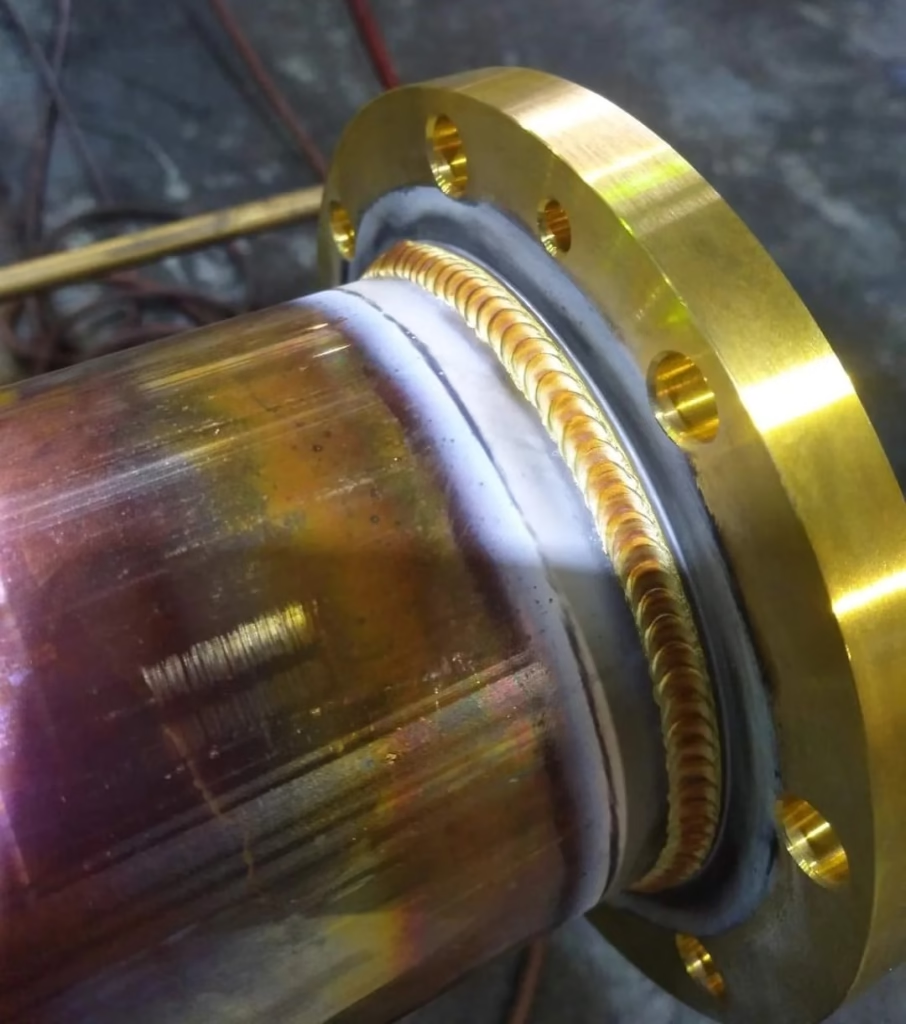

Welding Copper and Brass

Welding copper and brass isn’t like welding your typical mild steel. These two non-ferrous metals bring unique benefits—and their own set of challenges—to the fabrication table. From decorative metalwork to complex industrial systems, copper and brass are utilized in areas where conductivity, corrosion resistance, and aesthetics are crucial. But welding them requires a good grasp of metallurgy, the right filler materials, and carefully controlled heat. Let’s explore this intricate and rewarding topic in depth.

Importance in Industry and Fabrication

Copper and brass are everywhere—from plumbing and HVAC systems to musical instruments and electrical contacts. Their excellent conductivity, corrosion resistance, and workability make them ideal for many fabrication needs. Welding is often required when these materials need to be joined permanently and reliably.

Challenges in Welding Non-Ferrous Metals

Unlike steel, copper and brass are notorious for their high thermal conductivity and susceptibility to heat-related problems. This makes controlling heat input, preventing defects, and choosing the right welding method all the more critical. Without proper technique, you’re likely to face warping, cracking, or porosity.

Material Characteristics

Copper: Properties and Composition

Pure copper is soft, ductile, and an excellent conductor of heat and electricity. However, this conductivity makes it hard to weld—it dissipates heat quickly, requiring higher amperage and preheating.

Brass: Composition and Metallurgical Behavior

Brass is an alloy of copper and zinc. Depending on the zinc content, brass can be more or less weldable. As zinc boils at lower temperatures than copper melts, overheating can cause zinc to vaporize, leading to porosity and toxic fumes.

Thermal Conductivity and Its Effect on Welding

Copper and brass draw heat away from the weld zone rapidly. This means that welders often need to crank up the amperage and may require preheating to maintain a stable weld pool. Improper heat control often results in lack of fusion or weak joints.

Welding Techniques Suitable for Copper and Brass

TIG Welding (GTAW)

TIG welding is the go-to method for welding both copper and brass due to its precision and control. It works best for thinner sections or critical joints.

Why TIG is Preferred for Thin Sections

The ability to carefully control the arc and filler deposition makes TIG ideal when welding thin-walled copper tubing or decorative brass components. It produces a clean, high-quality weld with minimal oxidation.

MIG Welding (GMAW)

MIG welding is effective for thicker sections or repetitive jobs involving copper or brass, especially in automated environments.

Use in Mass Production and Brass Sheet Welding

When production speed is important, MIG can offer higher deposition rates. However, it may not provide the same level of quality as TIG in cosmetic or precision applications.

Oxy-Acetylene Welding

This older technique is still useful for brass, especially when welding small fittings or for repairs where electric welding may not be feasible.

Traditional Approach Still Relevant

Because it allows gentle preheating and broader control of the heat zone, oxy-acetylene remains a good choice for thin brass components where TIG may be too aggressive.

Brazing and Soldering as Alternative Joining Methods

When full fusion isn’t necessary, brazing and soldering can be excellent alternatives. They reduce the risk of overheating and allow joining dissimilar metals like copper to steel.

Electrode and Filler Material Selection

Recommended Filler Rods for Copper

For TIG welding, ERCu (deoxidized copper) rods are typically used. These fillers help avoid oxidation and ensure better arc stability and fusion.

Filler Selection for Brass (with Zinc Content Consideration)

Silicon bronze (ERCuSi-A) is often used for brass. It helps limit zinc loss and provides good corrosion resistance. For brazing, low-zinc brass or silver-based fillers are recommended.

Joint Design and Fit-Up Considerations

Joint Preparation for Copper Welding

Because of copper’s oxide layer, cleaning the joint thoroughly with a stainless steel wire brush or pickling solution is critical. Tight fit-up is essential to prevent heat loss and ensure consistent fusion.

Brass Joint Fit-Up and Heat Control

For brass, joint gaps must be carefully controlled to minimize zinc vaporization. Tighter joints allow for lower heat input and more predictable results.

Preheating and Interpass Temperature

Why Preheating is Critical for Copper

Preheating copper—typically to 300–500°F—slows down the rapid heat dissipation and allows the weld pool to form more easily. It also reduces the risk of cracking due to thermal shock.

Controlling Zinc Evaporation in Brass

Preheating should be moderate for brass (around 200–400°F), as excessive temperatures will cause zinc fumes. It’s best to use fast travel speeds and lower amperage when possible.

Welding Parameters and Heat Input

High Amperage Requirements for Copper

Due to its high thermal conductivity, copper usually demands 200–400 amps, depending on thickness. Welders must balance high heat input with cooling control to avoid warping.

Heat Control and Travel Speed for Brass

With brass, slower travel speed can lead to excessive zinc loss. Welders must move quickly, keeping the puddle small and avoiding excessive buildup of heat.

Common Defects and Troubleshooting

Porosity and Zinc Fuming

Porosity is a frequent issue with brass due to vaporized zinc. Adequate shielding gas, proper filler choice, and moderate heat input can reduce this risk.

Cracking and Thermal Stress

Both copper and brass are prone to hot cracking if not preheated properly or if cooled too quickly. Stress-relieving methods or slow cooling may be necessary for thick sections.

Oxidation and Discoloration

These materials oxidize rapidly under heat. Use argon shielding, back purging (if needed), and post-weld cleaning to restore the metal’s appearance.

Post-Weld Cleaning and Finishing

Descaling and Pickling Methods

After welding, oxide layers must be removed using acid pickling or abrasives. This not only improves appearance but also prevents corrosion.

Polishing for Aesthetic Applications

For decorative brass work, polishing and buffing are essential. Use progressively finer grits, followed by a polishing compound for a mirror finish.

Safety Considerations

Zinc Fume Hazards When Welding Brass

Inhalation of zinc fumes can lead to “metal fume fever.” Always weld brass in well-ventilated areas or use fume extractors.

Ventilation and PPE Requirements

Wear a proper respirator if fume extraction isn’t available. Always use gloves, long sleeves, and safety goggles to avoid burns and UV exposure.

Applications and Industry Use Cases

Copper Welding in HVAC and Electrical

Copper is widely used in HVAC piping and electrical grounding systems. TIG welding ensures leak-proof, clean welds for sensitive systems.

Brass in Decorative and Plumbing Work

Brass is commonly found in furniture, lighting, musical instruments, and fittings. Aesthetic welds with minimal discoloration are especially valued here.

FAQs

What is the best method to weld copper without distortion?

TIG welding with proper preheating and heat control is the most effective way to prevent distortion in copper, especially for thin materials.

Can MIG welding be used on brass?

Yes, MIG welding can be used on brass, but it’s less precise than TIG. Use a silicon bronze wire and keep travel speed fast to reduce zinc loss.

How do I control zinc fumes during brass welding?

Weld in a well-ventilated area, avoid overheating, use appropriate filler metal, and wear a fume-rated respirator if needed.

What filler metal is ideal for joining copper to steel?

Use a silver-based or silicon bronze brazing filler for dissimilar metal joints between copper and steel.

Is TIG welding better than brazing for copper pipes?

For high-strength, leak-proof joints, TIG is superior. However, brazing is easier, faster, and sufficient for many plumbing applications.

Conclusion

Welding copper and brass is a complex but rewarding process. It demands a deep understanding of the metals’ properties, a precise selection of welding techniques and consumables, and strong attention to heat management. With the right skills and equipment, fabricators can achieve beautiful, functional welds that meet the highest standards of both appearance and performance.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders