What is IR Welding?

Introduction

Definition of Infrared Welding

Infrared welding (IR Welding) is a welding technique that utilizes infrared radiation to generate heat and create a weld between thermoplastic materials. It is a non-contact heating process where the energy from infrared radiation is absorbed by the surface of the workpieces, leading to localized melting and subsequent bonding when pressure is applied.

Brief overview of its applications and advantages

Infrared welding has gained popularity in various industries due to its unique advantages and applications. Some of the notable points include:

- Plastic Industry: Infrared welding is extensively used in the plastic industry for joining thermoplastic materials. It enables efficient and high-quality welding of components such as automotive parts, electronic housings, medical devices, and consumer products. The technique offers precise control over the heating process, resulting in strong and visually appealing welds.

- Automotive Sector: Infrared welding plays a crucial role in automotive manufacturing. It is employed for joining plastic components, such as interior trim, bumpers, tail lights, and air intake systems. The process provides fast and reliable bonding, ensuring the structural integrity and appearance of automotive parts.

- Electronics Manufacturing: Infrared welding is utilized in electronics manufacturing for joining plastic components of devices like mobile phones, tablets, and computer housings. The non-contact heating process minimizes the risk of heat damage to sensitive electronic components, making it suitable for delicate assemblies.

- Medical Device Industry: Infrared welding finds application in the medical device industry for joining plastic components of devices like surgical instruments, drug delivery systems, and diagnostic equipment. The technique offers clean and precise welds, maintaining the integrity and cleanliness required for medical applications.

- Other Industries: Infrared welding has applications in various other industries, including consumer goods, packaging, and appliances. It provides an efficient and cost-effective solution for joining thermoplastic materials, ensuring strong, durable, and aesthetically pleasing welds.

The advantages of infrared welding include:

- Fast and efficient heating: Infrared radiation allows for rapid and localized heating of the workpiece, reducing cycle times and increasing productivity.

- Non-contact heating process: The absence of physical contact between the heat source and the workpiece eliminates the risk of contamination and damage to sensitive surfaces.

- Precise and localized heat application: Infrared radiation can be focused on specific areas, allowing for precise control over the heating process and minimizing thermal stress on surrounding regions.

- Ability to weld large and complex parts: Infrared welding can effectively join large and intricate plastic components that may be challenging to weld using other methods.

These advantages make infrared welding a preferred choice for many industries seeking efficient, reliable, and visually appealing welds in thermoplastic materials.

Principle of Infrared Welding

Explanation of the basic principle

Infrared welding utilizes infrared radiation to generate heat and facilitate the bonding of thermoplastic materials. The process involves the following steps:

- The workpieces to be welded are positioned and aligned.

- An infrared radiation source emits high-intensity infrared radiation towards the joint interface.

- The infrared radiation is absorbed by the surface of the thermoplastic materials, converting the radiant energy into heat.

- As the heat is generated, the material softens and reaches a molten state near the joint interface.

- Pressure is applied to the softened material, causing it to flow and form a bond between the workpieces.

- The pressure is maintained until the molten material solidifies, creating a strong and durable weld.

Description of the equipment and components used

The equipment and components used in infrared welding typically include:

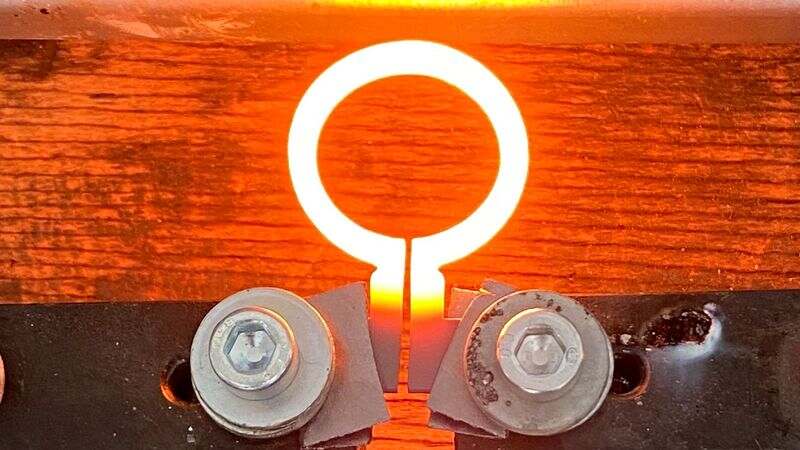

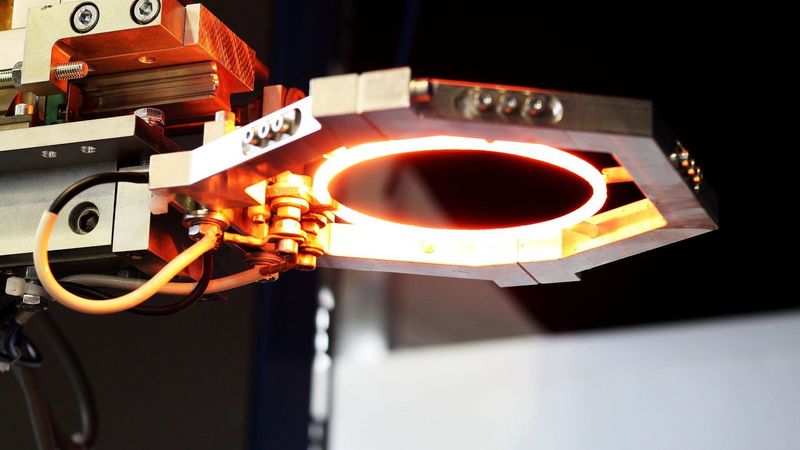

- Infrared Radiation Source: This is a high-intensity source that emits infrared radiation, usually in the form of a halogen or quartz lamp. The radiation source should emit wavelengths that are suitable for the absorption characteristics of the thermoplastic materials being welded.

- Reflectors: Reflectors are used to focus and direct the emitted infrared radiation towards the joint interface. They help optimize the heating efficiency and ensure that the radiation is concentrated on the desired welding area.

- Fixtures and Clamps: Fixtures and clamps are used to securely hold the workpieces in position during the welding process. They ensure proper alignment and prevent any movement or misalignment that could affect the quality of the weld.

- Control System: A control system regulates and monitors various parameters of the welding process. It may include controls for the heating time, temperature, and pressure applied during the welding operation. The control system ensures consistent and reliable welding results.

Role of infrared radiation in the process

Infrared radiation plays a crucial role in the welding process:

- Heat Generation: The emitted infrared radiation is absorbed by the surface of the thermoplastic materials. The absorption of the radiation by the materials leads to the conversion of radiant energy into heat energy, raising the temperature of the workpieces.

- Softening and Melting: The heat generated by the infrared radiation causes the thermoplastic materials to soften and reach a molten state near the joint interface. This softening enables the materials to flow and bond when pressure is applied.

- Controlled Heating: The focused infrared radiation allows for precise and localized heating of the desired welding area. This localized heating minimizes the heat-affected zone and helps maintain the structural integrity and aesthetics of the surrounding regions.

The efficient utilization of infrared radiation in the welding process ensures controlled and effective heating, resulting in strong and reliable welds in thermoplastic materials.

Process Steps

Pre-welding Preparation

- Selection of suitable materials for infrared welding: The materials to be joined using infrared welding should be thermoplastic in nature. Suitable materials include various types of plastics, such as polyethylene, polypropylene, polycarbonate, and polyamide. Compatibility between the materials is crucial to ensure proper bonding.

- Machining and cleaning of workpieces: The workpieces undergo machining processes to achieve the desired shape and dimensions. Machining may involve cutting, milling, or other techniques to prepare the surfaces for welding. The surfaces should be clean and free from contaminants, such as dust, oils, or greases, to ensure optimal bonding.

- Fixturing and alignment of the components: The workpieces are securely positioned and aligned using fixtures or clamps. Proper alignment ensures that the joint interface is accurately positioned for effective heat transfer and bonding. Fixturing helps maintain the desired orientation and stability of the components during the welding process.

Heating Phase

- Activation of the equipment and setup of welding parameters: The infrared welding equipment is activated, and the necessary parameters are set. This includes adjusting the power output of the infrared radiation source, controlling the heating time, and monitoring the temperature to achieve the desired heating profile.

- Introduction of infrared radiation: The infrared radiation source is positioned and focused on the joint interface of the workpieces. The emitted radiation is directed towards the welding area, ensuring that the desired region receives the necessary heat for melting and bonding.

- Absorption and conversion of infrared energy into heat: The thermoplastic materials absorb the infrared radiation and convert the radiant energy into heat. The absorbed energy raises the temperature of the workpieces, softening the material near the joint interface and allowing it to reach a molten state ready for bonding.

Welding Phase

- Control and monitoring of heating time and temperature: The heating time and temperature are carefully controlled and monitored to achieve optimal softening and melting of the thermoplastic materials. The heating parameters vary depending on the materials being welded and the desired quality of the weld.

- Application of pressure to create a weld: Once the desired temperature is reached, pressure is applied to the softened and molten materials. The pressure ensures intimate contact and promotes material flow and intermixing, facilitating the formation of a strong weld between the workpieces.

- Cooling and solidification of the welded joint: After the application of pressure, the pressure is maintained while the molten material cools and solidifies. Cooling can be achieved through natural cooling or by applying controlled cooling methods to ensure proper solidification of the weld. This cooling phase helps to strengthen the bond between the workpieces.

Post-welding

- Inspection and testing of the weld quality: The welded joint undergoes inspection and testing to ensure its quality and integrity. Various non-destructive testing methods, such as visual inspection, ultrasonic testing, or mechanical testing, may be employed to verify the strength and reliability of the weld.

- Post-weld processing or finishing, if required: Depending on the specific application or aesthetic requirements, post-weld processing or finishing may be performed. This can involve trimming excess material, surface smoothing, or other operations to achieve the desired final appearance and functionality of the welded components.

The process steps outlined above provide a general overview of the infrared welding process. Specific parameters and techniques may vary based on the materials being joined, equipment used, and desired weld characteristics.

Advantages and Limitations

Advantages of Infrared Welding

- Fast and efficient heating: Infrared welding offers rapid heating capabilities, allowing for shorter cycle times compared to other welding methods. The focused and intense heat generated by the infrared radiation quickly raises the temperature of the thermoplastic materials, facilitating efficient melting and bonding.

- Non-contact heating process: Infrared welding is a non-contact heating process, meaning that the heat is generated without direct physical contact between the heat source and the workpieces. This eliminates the risk of contamination or damage to the surfaces being welded, particularly when working with delicate or sensitive materials.

- Precise and localized heat application: The focused nature of infrared radiation enables precise control over the heating process. It allows for the localized application of heat to specific areas of the workpieces, minimizing the heat-affected zone and reducing the potential for thermal distortion or damage to surrounding regions.

- Ability to weld large and complex parts: Infrared welding can effectively join large and complex parts due to its non-contact nature. It offers flexibility in accommodating workpieces of various shapes and sizes, making it suitable for applications where traditional welding methods may be limited.

Limitations and Considerations

- Material compatibility and transparency to infrared radiation: Infrared welding is primarily applicable to thermoplastic materials that are transparent or partially transparent to infrared radiation. The materials must have sufficient absorption properties to convert the radiation into heat. Some thermoplastics, such as polyethylene and polypropylene, respond well to infrared welding, while others may not be suitable.

- Surface finish and cleanliness requirements: Infrared welding requires clean and well-prepared surfaces to achieve optimal bonding. Any surface contaminants, such as dirt, oils, or residues, can interfere with the absorption of infrared radiation and impact the quality of the weld. Therefore, proper surface cleaning and preparation are essential for successful infrared welding.

- Equipment cost and complexity: The equipment required for infrared welding can be relatively expensive compared to some other welding methods. The specialized infrared radiation sources, reflectors, and control systems contribute to the overall cost. Additionally, the setup and operation of the equipment may require training and expertise, adding to the complexity of the process.

It is important to consider these advantages and limitations when evaluating the suitability of infrared welding for specific applications. While the technique offers several benefits, careful assessment of material compatibility, surface preparation, and equipment considerations is necessary to ensure successful implementation.

Applications of Infrared Welding

Plastic Industry

Infrared welding has widespread use in the plastic industry for joining thermoplastic materials. Some specific applications include:

- Automotive components: Infrared welding is employed for joining plastic parts in automotive interiors, such as dashboard components, door panels, and consoles.

- Packaging industry: Infrared welding is utilized for manufacturing plastic packaging, including containers, bottles, and caps.

- Consumer goods: Various consumer products, such as appliances, toys, and household items, benefit from infrared welding for seamless and strong bonding of plastic components.

Automotive Sector

In the automotive industry, infrared welding finds numerous applications due to its ability to join plastic components efficiently and reliably. Some notable examples include:

- Exterior trim: Infrared welding is used for bonding exterior trim components, such as bumper covers, grilles, and side moldings.

- Lighting assemblies: Infrared welding joins plastic lenses, reflectors, and housings of automotive lights, such as headlights, taillights, and signal lights.

- Air intake systems: Components like intake manifolds, air ducts, and resonators are commonly welded using infrared welding in the automotive sector.

Electronics Manufacturing

Infrared welding plays a significant role in the electronics manufacturing industry, where precise and non-damaging joining techniques are crucial. Some applications include:

- Mobile devices: Infrared welding is employed for joining plastic components of smartphones, tablets, and laptops, ensuring secure and durable assembly.

- Computer and audiovisual equipment: Plastic parts of computer towers, monitors, keyboards, and speakers are often joined using infrared welding.

- Consumer electronics: Products like remote controls, gaming consoles, and audio devices utilize infrared welding for the assembly of plastic housings and internal components.

Medical Device Industry

In the medical device industry, infrared welding offers advantages in terms of clean, precise, and reliable joining. Applications include:

- Surgical instruments: Infrared welding is used for joining plastic components of surgical instruments, ensuring proper functionality and cleanliness.

- Drug delivery systems: Devices like inhalers, insulin pens, and drug-dispensing equipment benefit from infrared welding for secure and hygienic assembly.

- Diagnostic equipment: Plastic components of medical devices such as blood glucose meters, imaging devices, and monitoring equipment are commonly welded using infrared welding.

Other Industries

In addition to the above sectors, infrared welding has applications in various other industries, including:

- HVAC and plumbing: Joining plastic components of heating, ventilation, air conditioning systems, and plumbing fixtures.

- Industrial equipment: Welding plastic parts of machinery, pumps, valves, and industrial enclosures.

- Aerospace and aviation: Joining plastic components in aircraft interiors, including cabin panels, overhead bins, and seating components.

- Renewable energy: Assembling plastic parts in solar panels, wind turbines, and battery systems.

The versatility and benefits of infrared welding make it a valuable joining technique in numerous industries, where precise, reliable, and visually appealing welds in thermoplastic materials are essential.

FAQs

What is the use of infrared welding?

Infrared welding is used to join thermoplastic materials efficiently and reliably in various industries such as automotive, electronics, and medical devices.

What is the process of infrared welding?

Infrared welding involves using focused infrared radiation to heat thermoplastic materials until they reach a molten state. Pressure is applied to create a bond between the softened materials, resulting in a strong weld.

What is the full form of IR welding?

The full form of IR welding is “Infrared Welding.”

What is thermal welding application?

Thermal welding is used for joining thermoplastic materials using heat. It finds application in industries such as automotive, packaging, and consumer goods.

How does an infrared device work?

An infrared device emits focused infrared radiation that transfers heat to the target material. The material absorbs the radiation, converting it into heat energy, which raises the temperature and allows for welding or other desired processes.

What is infrared heat processing?

Infrared heat processing refers to the application of controlled infrared heat for various industrial processes, including welding, drying, curing, and heat treatment. It provides efficient and precise heat transfer to the target materials.

What material is thermal welding?

Thermal welding is commonly used for joining thermoplastic materials such as polyethylene, polypropylene, polycarbonate, and PVC.

What is an example of thermal welding?

Ultrasonic welding is an example of thermal welding, where high-frequency mechanical vibrations generate heat to melt and bond thermoplastic materials.

Which heat is used in welding?

Various heat sources can be used in welding, depending on the welding process. Common heat sources include flame (e.g., oxy-fuel welding), electric arcs (e.g., shielded metal arc welding), and focused heat energy (e.g., laser welding, infrared welding).

What is IR heat flux?

IR heat flux refers to the rate at which heat is transferred through infrared radiation. It measures the amount of heat energy flowing per unit area per unit time.

What is RF welding machine?

An RF (Radio Frequency) welding machine utilizes electromagnetic energy at radio frequencies to heat and weld certain types of thermoplastic materials together. It is commonly used in applications such as sealing seams in fabrics or plastics.

Why is it called resistance welding?

Resistance welding is so named because the welding process involves passing an electric current through the workpieces, creating resistance at the joint interface. This resistance generates heat, which melts and bonds the materials together, forming a weld.

Conclusion

In conclusion, IR welding is a highly efficient and versatile welding technique that offers numerous benefits in various industries. This innovative method uses infrared radiation to heat and fuse materials together without the need for additional filler materials or open flames.

IR welding has proven to be particularly advantageous in joining thermoplastic materials, such as PVC, polyethylene, and polypropylene. It provides a clean, precise, and reliable bonding process, resulting in strong, durable, and aesthetically pleasing welds. The use of infrared radiation allows for controlled and localized heating, minimizing the risk of thermal damage to the surrounding area.

One of the key advantages of IR welding is its ability to achieve fast cycle times, making it suitable for high-volume production environments. The process is highly automated and can be easily integrated into existing manufacturing systems, increasing productivity and reducing labor costs. Additionally, the absence of consumables or adhesives makes IR welding a cost-effective solution in the long run.

Furthermore, IR welding offers environmental benefits as it eliminates the need for solvents, adhesives, or other chemicals traditionally used in welding processes. This reduces waste generation and eliminates potential health and safety concerns associated with the use of hazardous substances. The precise control over the heating process also minimizes energy consumption, making it an energy-efficient welding method.

Despite its many advantages, IR welding does have certain limitations. It is primarily suited for joining thermoplastic materials and may not be suitable for all types of materials or applications. Additionally, the initial setup cost for implementing IR welding equipment may be higher compared to traditional welding methods. However, these drawbacks are outweighed by the numerous benefits offered by IR welding.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders