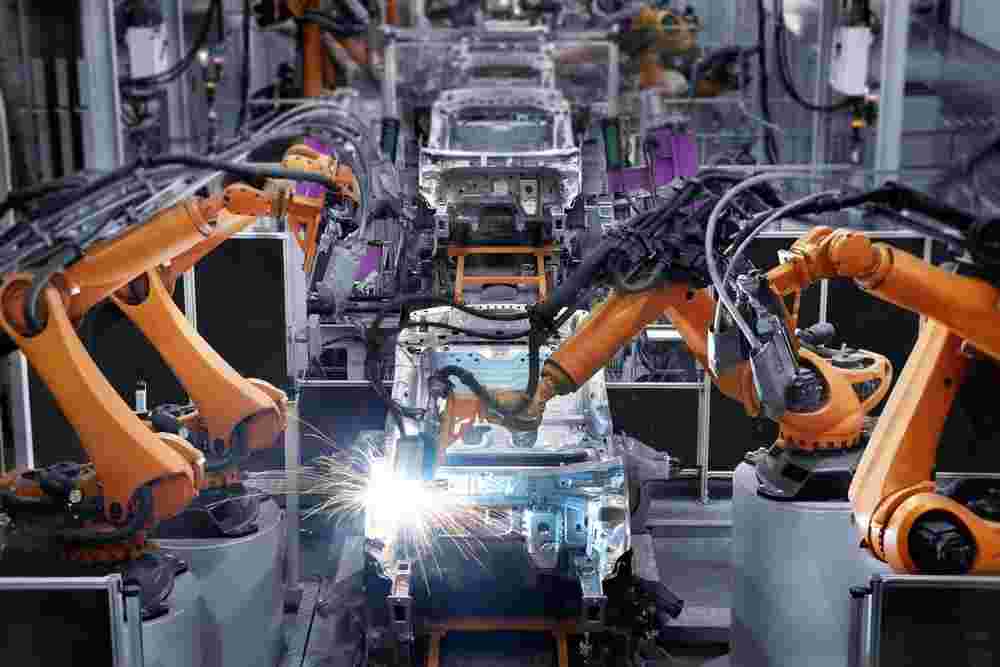

Robotic Welding in the Automotive Industry

In the fast-paced world of automotive manufacturing, innovation and efficiency are paramount. Robotic welding, a groundbreaking technological advancement, has emerged as a game-changer in the industry. This article delves into the transformative impact of robotic welding in the automotive sector, examining its benefits, applications, and future prospects.

Introduction

Robotic welding in the automotive industry has revolutionized the way vehicles are produced. This cutting-edge technology combines automation with precision, resulting in enhanced productivity and consistently high-quality welds. Let’s delve deeper into how this revolutionary process is reshaping the manufacturing landscape.

Applications in Automotive Manufacturing

Robotic welding is extensively employed in various stages of automotive manufacturing. From chassis assembly to body fabrication, robots equipped with advanced welding arms have become essential tools. These robots offer unparalleled accuracy, repeatability, and speed, leading to a reduction in production time and operational costs.

Advantages of Robotic Welding

The advantages of incorporating robotic welding in the automotive sector are manifold. First and foremost, it significantly enhances weld quality. Robots can consistently produce flawless welds, minimizing defects and ensuring structural integrity. Additionally, robotic welding reduces the exposure of human welders to hazardous fumes and intense heat, promoting a safer working environment.

Efficiency and Precision

Robotic welding systems are designed to work tirelessly without fatigue, leading to increased productivity. The precise movements of robotic arms ensure that welds are executed with utmost accuracy, resulting in stronger and more durable joints. The ability to work around the clock also translates to quicker production cycles.

Cost Savings and Scalability

While the initial investment in robotic welding technology can be substantial, the long-term cost savings are remarkable. Robots can operate non-stop, minimizing downtime associated with shift changes and breaks. Moreover, as automotive production demands increase, it’s easier to scale up robotic welding operations compared to hiring and training additional human welders.

Future Trends and Innovations

As technology evolves, so does robotic welding. The automotive industry is witnessing the integration of artificial intelligence (AI) and machine learning into robotic welding systems. These advancements enable robots to adapt to varying materials, joint designs, and welding parameters, making them even more versatile and efficient.

FAQs

What are the robots for welding in the automotive industry?

Robots for welding in the automotive industry are specialized machines designed to perform welding tasks with precision and efficiency. These robots are equipped with advanced welding arms and sensors that allow them to weld various components of vehicles, such as chassis, body panels, and structural elements. They can execute welds consistently and accurately, leading to enhanced weld quality and reduced production time.

How are robotics used in the automotive industry?

Robotics are extensively used in the automotive industry for a wide range of tasks beyond welding. Robots are employed in assembly lines for tasks like material handling, painting, quality inspection, and more. In welding specifically, robots are programmed to follow welding paths with utmost precision, ensuring that welds are strong and consistent. This level of automation enhances efficiency, reduces human error, and promotes safer working conditions.

What industries is robotic welding used for?

Robotic welding is not limited to the automotive industry alone. It is utilized across various sectors that require precise and consistent welding. Industries such as aerospace, construction, shipbuilding, electronics, and heavy machinery manufacturing also benefit from robotic welding technology. Essentially, any industry that requires repetitive and accurate welding processes can make use of robotic welding systems.

What is the application of welding in the automotive industry?

Welding plays a crucial role in the automotive industry by joining different metal components to create the structural framework of vehicles. This includes welding tasks in chassis assembly, body construction, and engine manufacturing. Welding ensures that the vehicle’s components are securely joined, contributing to the overall safety and durability of the vehicle.

What are the applications of robot welding?

Robot welding has numerous applications across industries. Apart from the automotive sector, it’s used in aerospace to weld aircraft components, in construction for structural welding, in electronics for circuitry connections, and in general manufacturing for fabricating various products. The ability of robotic systems to consistently perform precise welds makes them valuable in any context where accuracy and repeatability are essential.

What is an example of robotic welding?

An example of robotic welding can be observed in the automotive industry’s body assembly process. Imagine the construction of a car’s chassis. Robotic welding arms are programmed to precisely join metal components, such as frame rails and cross members, using welding techniques like MIG (Metal Inert Gas) welding. The robots follow predetermined paths, ensuring that each weld is made with the exact specifications required. This consistent and accurate welding process results in a strong and durable chassis that forms the foundation of the vehicle.

Conclusion

In conclusion, robotic welding has ushered in a new era of manufacturing in the automotive industry. Its ability to combine efficiency, precision, and cost-effectiveness has made it an indispensable tool in modern vehicle production. As technology continues to evolve, we can expect robotic welding to play an increasingly pivotal role in shaping the future of automotive manufacturing.

For more in-depth information about robotic welding technology, you can refer to resources such as [SourceLink1] and [SourceLink2], which provide valuable insights into the technical aspects of this groundbreaking innovation.

Remember, embracing robotic welding is not just a trend; it’s a strategic move that positions automotive manufacturers at the forefront of efficiency and innovation. As the automotive industry continues to evolve, robotic welding will remain a driving force behind its transformation.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders