Leak Testing for Welds: Ensuring Quality and Safety

Introduction

In the intricate world of welding, ensuring the integrity of welds is paramount. One crucial aspect of this assurance is leak testing, a process designed to detect any imperfections or vulnerabilities in welded structures.

Importance of Leak Testing

Leak testing plays a pivotal role in guaranteeing the reliability and safety of welds. The consequences of undetected leaks can range from structural failures to environmental hazards. This article delves into the various methodologies employed in leak testing for welds and sheds light on their significance.

Types of Leak Testing for Welds

Visual Inspection

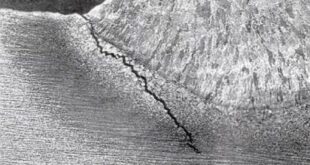

Visual inspection serves as the initial step in leak testing. It involves a meticulous examination of welds for any visible defects, such as cracks, pores, or incomplete penetration.

Pressure Testing

Pressure testing entails subjecting the welds to varying levels of pressure to identify potential leaks. This method is effective in uncovering weaknesses that might not be apparent through visual inspection alone.

Vacuum Testing

Vacuum testing operates on the principle of creating a vacuum around the welds and observing for any pressure differentials. This method is particularly useful for detecting small leaks that might be missed in other tests.

Ultrasonic Testing

Ultrasonic testing utilizes sound waves to identify irregularities in welds. It is a non-destructive method that offers precise insights into the structural integrity of the weld.

Welding Standards and Regulations

Adhering to welding standards and regulations is imperative for industries. Compliance ensures that the welding processes meet the necessary criteria, emphasizing the importance of leak testing as a quality control measure.

Common Causes of Weld Leaks

Understanding the common causes of weld leaks is crucial for prevention. Factors such as poor welding techniques, material defects, or inadequate preparation can contribute to leaks.

Advancements in Leak Testing Technologies

Technological advancements have significantly improved leak testing methodologies. Automated systems, computerized analysis, and real-time monitoring are enhancing the accuracy and efficiency of leak detection.

Benefits of Early Leak Detection

Early detection of leaks translates to cost savings and prevents potential disasters. Timely identification allows for prompt repairs, reducing downtime and ensuring the longevity of the welded structures.

Challenges in Leak Testing

While leak testing is a critical process, it comes with challenges. Accessing certain weld areas, the sensitivity of some testing methods, and the need for highly skilled personnel are factors that can pose challenges.

Case Studies: Successful Leak Testing Applications

Examining real-world applications of successful leak testing provides insights into the efficacy of different methodologies. Case studies highlight how industries have benefited from rigorous leak testing protocols.

Tips for Effective Leak Testing

Implementing effective leak testing requires attention to detail. This section provides practical tips to enhance the accuracy and reliability of leak testing procedures.

Environmental Impact and Leak Testing

The environmental impact of leak testing is an emerging concern. This section explores eco-friendly approaches to leak testing and their significance in the context of sustainability.

Future Trends in Leak Testing for Welds

Anticipating the future of leak testing involves exploring emerging technologies and methodologies. This section provides a glimpse into the potential advancements in ensuring weld integrity.

FAQs

How often should leak testing be performed on welds?

Leak testing frequency on welds varies, depending on industry standards and specific project requirements.

Can automated leak testing systems replace manual inspection entirely?

While automated leak testing systems enhance efficiency, manual inspection may still be necessary for complex welds requiring human judgment.

Are there specific industries where leak testing is more critical?

Leak testing is particularly critical in industries such as pharmaceuticals, petrochemicals, aerospace, and nuclear, where fluid or gas containment is crucial.

What are the potential health hazards associated with leak testing?

Health hazards in leak testing vary with methods and substances; adherence to safety guidelines and proper protective measures are essential.

How do I choose the most suitable leak testing method for my welding application?

Conclusion

In conclusion, leak testing for welds is a critical aspect of quality assurance in welding processes. From visual inspections to advanced ultrasonic testing, each method contributes to the overall reliability and safety of welded structures.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders