Best Ways to Ensure Welding Safety

Introduction

Welding is a critical process used in various industries, from construction to manufacturing. While it is a valuable skill, it also comes with inherent risks. Ensuring welding safety is of utmost importance to protect both welders and those around them. This comprehensive article will guide you through the best practices and safety measures to follow while welding. Learn how to safeguard yourself and others while maintaining the highest level of productivity.

Best Ways to Ensure Welding Safety?

Welding safety is not just about donning protective gear; it involves adopting a holistic approach to minimize potential risks. Here are the best ways to ensure welding safety:

Proper Training and Certification

One of the foundational pillars of welding safety is adequate training and certification. Ensure that all personnel involved in welding operations have received comprehensive training from accredited institutions. Proper training instills the necessary skills and knowledge to handle welding equipment, fuels, and potential hazards.

Use of Personal Protective Equipment (PPE)

Welding produces intense heat, sparks, and harmful fumes, making the use of PPE crucial. Welders should wear flame-resistant clothing, welding gloves, welding helmets with appropriate filters, and safety glasses. Additionally, respiratory protection like respirators is essential to prevent inhalation of dangerous fumes.

Inspection and Maintenance of Equipment

Regular inspection and maintenance of welding equipment are vital to ensure optimal performance and minimize safety risks. Equipment malfunctions can lead to accidents, so welders must examine their tools before each use. If any defects are found, repairs or replacements should be made promptly.

Create a Well-Ventilated Workspace

Welding fumes contain hazardous gases that can be harmful when inhaled. Ensure your workspace is well-ventilated to disperse fumes effectively. Positioning fans or exhaust systems to direct fumes away from the welder is a recommended practice.

Fire Prevention and Fire Watch

Welding involves high temperatures and sparks, which can ignite flammable materials in the vicinity. Implement fire prevention measures, such as clearing the work area of flammable substances and having fire extinguishers readily available. Additionally, assign someone as a fire watch during welding operations to quickly respond to any potential fires.

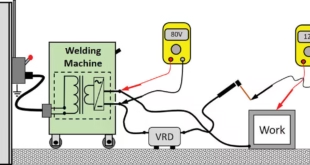

Secure Grounding and Electrical Safety

Maintaining proper grounding of welding equipment is essential for electrical safety. Improper grounding can lead to electrical shocks or electrocution. Welders should regularly inspect cables, connectors, and grounding clamps to ensure they are in good condition.

Safe Handling of Compressed Gas Cylinders

Welding often involves the use of compressed gas cylinders, which can be hazardous if mishandled. Follow guidelines for the proper storage, transportation, and handling of these cylinders to avoid accidents.

Use of Welding Curtains and Screens

Welding curtains and screens act as a barrier, protecting others from harmful rays and sparks generated during welding. Implementing these safety measures in the workplace helps maintain a safe environment for everyone.

Preventing Electric Shock

Electric shock is a significant concern during welding operations. To prevent it, welders should never touch the electrode or metal parts of the welding circuit when they are in contact with the workpiece or ground. Insulating gloves and dry conditions are essential safeguards.

Eliminate Tripping Hazards

A cluttered workspace can lead to trips and falls, which are especially dangerous during welding. Keep the area tidy and free from obstacles to prevent accidents.

Employ Remote Welding Techniques

When possible, use remote welding techniques, such as robotic welding, to reduce the risk of injury to human welders. These methods allow welding in hazardous environments without direct human involvement.

Be Mindful of Welding Fume Exposure Limits

Different welding processes produce varying levels of fumes, and exposure to certain fumes can be harmful. Be aware of the permissible exposure limits (PELs) set by relevant authorities and take necessary precautions to stay within safe levels.

Safe Welding Positions

Choosing the right welding position is crucial for safety and efficiency. Evaluate the workpiece and select a comfortable and stable welding position to minimize fatigue and reduce the risk of accidents.

Safe Handling of Welding Electrodes

Electrodes are fundamental to welding processes, and handling them safely is essential. Proper storage and transportation, along with avoiding direct skin contact, are crucial steps to ensure safety.

Avoid Welding in Confined Spaces

Welding in confined spaces presents additional risks due to limited ventilation and potential exposure to toxic gases. Whenever possible, avoid welding in confined areas and opt for safer alternatives.

Implement Lockout/Tagout Procedures

Before performing any maintenance or repairs on welding equipment, implement lockout/tagout procedures to prevent accidental activation of machinery. This reduces the risk of injury during maintenance tasks.

Regular Safety Training and Refreshers

Safety protocols and best practices evolve over time. Conduct regular safety training sessions and refresher courses to keep welders informed about the latest safety measures.

Maintain a First Aid Kit

In the event of a minor injury, having a well-equipped first aid kit readily available can make a significant difference. Ensure all welders know the location of the first aid kit and are familiar with its contents.

Safe Welding Around Water

Welding near water can be hazardous due to the risk of electrical shock. Take extra precautions when welding in wet or damp environments.

Use of Fire-resistant Screens and Blankets

Fire-resistant screens and blankets provide an extra layer of protection from sparks and flying debris. These safety measures are especially important when welding in crowded or sensitive areas.

Understanding Material Safety Data Sheets (MSDS)

MSDS provides critical information about welding materials and their associated hazards. Familiarize yourself with MSDS to ensure proper handling and disposal of materials.

Worksite Hazard Analysis

Conduct a thorough worksite hazard analysis before commencing welding operations. Identifying potential hazards and taking preemptive measures ensures a safer work environment.

Safe Welding in Adverse Weather Conditions

Extreme weather conditions can affect welding safety. Avoid welding in adverse weather whenever possible, and take necessary precautions if it is unavoidable.

Encourage Open Communication

Create an environment where welders feel comfortable discussing safety concerns. Encourage open communication about safety issues and potential improvements.

Continuous Improvement and Learning

Safety is an ongoing process. Encourage continuous improvement and learning about welding safety practices to stay updated with the latest advancements.

FAQs

What safety gear is essential for welding?

Welders should wear flame-resistant clothing, welding gloves, welding helmets with appropriate filters, safety glasses, and respiratory protection like respirators.

Why is proper grounding important in welding?

Proper grounding ensures electrical safety during welding operations, preventing electrical shocks or electrocution.

How can I prevent fire hazards during welding?

Implement fire prevention measures like clearing the work area of flammable substances, having fire extinguishers readily available, and assigning someone as a fire watch during welding.

What are the risks of welding in confined spaces?

Welding in confined spaces can lead to limited ventilation and potential exposure to toxic gases, posing additional safety risks.

How do remote welding techniques enhance safety?

Remote welding techniques, such as robotic welding, reduce the risk of injury to human welders by allowing welding in hazardous environments without direct human involvement.

Why is it crucial to understand Material Safety Data Sheets (MSDS)?

MSDS provides critical information about welding materials and their associated hazards, ensuring proper handling and disposal of materials.

Conclusion

By following these best ways to ensure welding safety, you can significantly reduce the risk of accidents and injuries during welding operations. Remember that welding safety is a collective responsibility, and everyone involved in the process must be vigilant and proactive in adhering to safety protocols. Prioritize proper training, equipment maintenance, and PPE usage to create a safe and productive welding environment. Stay informed about the latest safety practices and continuously improve your welding safety measures to ensure a successful and secure welding journey.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders