General Safety in Welding

Introduction

Welding is a hazardous activity. There are many health and safety risks for the workers doing their jobs in welding fields. Welding societies have designed safety measures to protect the welding works from health and other hazards. From time to time proper training is conducted to keep the works updated with safety rules and regulations. Welding workers should be aware of safety precautions and they should have proper apparel before performing any welding activity.

Careless or unauthorized use of machine tools and equipment could be dangerous for your own safety as well as for the people around you. So if you are not familiar with machinery, do not try to interfere with it. If you do not know how to use certain tools or equipment, avoid it and do not use it to conduct experiments on your own. The apparatus or materials could be dangerous for you if you don’t have proper instructions or guidelines to use them.

Causes of Accidents and Safety Measurements

There could be accidents in the workshop. There could be different causes of occurring accidents in the workshop area. But the main causes include; carelessness/ negligence, lack of knowledge, risk-taking, or interference with apparatus or machinery; wrong use of equipment/materials, for example, using files or drills, as hammers (it could cause fire/explosion).

1- Cleanliness of Workshop

The workplace/workshop should be clean and clear not messy or overloaded with tools. Because in most cases the untidiness or mess in the workshop causes people to fall, they could touch any sharp edges, glass objects, or machinery. Hence the workshop should be clean and there should not be any oil, grease, or extra metal or glass objects on the floor. The material in use should be rust-free and clean from dirt or any insulating material. if so they may cause poor weld quality and increase the use of electrodes. And it causes weld splash.

2- Care while dealing with Gases

Gases should be handled with care they could be dangerous and life-taking. Gases like oxygen, acetylene, propane, hydrogen, natural gas, coal gas, carbon monoxide, and liquid hydrocarbons like petrol, volatile oils, and paraffin are all explosion and fire risks if handled wrongly. The use of gases, other than recommended gases, could be dangerous, for example, the impact of a high-pressure air jet on the skin can produce an embolism and death; carbon dioxide, nitrogen, and argon can cause death by suffocation in unventilated spaces.

3- Safety Rules while Cutting Edges

Cutting edges could cause severe injury. So, always keep both hands behind the cutting edge for safety. Also be careful when machinery is involved for cutting purposes like saws, guillotines, lathes, shapers, millers, or grinders. Follow general safety rules while cutting. Do follow the while cutting:

- Wear safety glasses or a protective face shield while using cutters.

- Choose the proper type of cutter for a specific purpose as these are designed for a specific type, hardness, and size of material.

- Always keeps the material being cut, at right angles to the cutting edges of the jaws

- Also, be careful about the injury that could happen from flying metals. Take a burlap bag, cloth, or rag and wrap it around the cutting jaws.

- Also, warn other people in the work area to take precautionary measures to avoid possible injury from flying pieces of metal

- Never operate any machine without making sure that the safety guard is correctly fitted and in good order.

- Always keep your cutting tools in good repair and maintenance

- Keep cutter and moving parts lubricated if they are used daily.

- Sharpen jaws according to manufacturers’ instructions.

4- Injuries through Flying Objects

The molten metal could also cause damage to the person, so be careful from a spot-welding machine, flame-cutting- splinters, and grinding sparks. Take all safety precautions; always wear the recommended safety clothing. Use all other safety accessories i.e., goggles, aprons, boots, gloves, welding helmets, leather caps, and approved safety footwear.

5- Proper Safety Dress

Always wear proper clothing while doing welding, as improper dress could cause injuries or fatal accidents. Tie your hair properly as long hair is a fire risk when you are engaged in welding. So wear recommended welding safety cap. Avoid wearing dress items like ties, belts, unfastened shirt-sleeves or coats as they could cause accident. For example, a dangling tie or shirt sleeve could wrap around a rotating shaft and pull you into machinery.

6- Electrical Safety

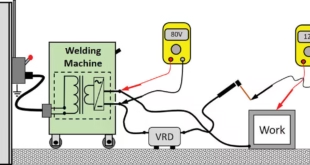

Electrical safety is also important. Low voltages could also become risky so don’t interfere with any electrical apparatus. If something went wrong, report it to your supervisor. Do not try to examine it yourself as it could lead to serious electrical shock.

Electrical shock Treatment

To free the victim from contact with the electricity follow these steps:

- Switch off the current immediately or get someone to do so

- Do not attempt to remove a person from contact with a high-voltage source unless suitable equipment, insulated for the system voltage, is available.

- When attempting to free a person from contact with low or medium voltage use rubber gloves, rubber boots and a rubber mat, or an insulated stick

- If these are not available use a loop of rope, a cap, or a coat to drag the person free.

- whatever is used must be non-conducting

- After release, lay the patient down on something dry, if possible

- If there is no sign of breathing immediately proceed with artificial respiration and send someone for a doctor and ambulance.

Other injuries through Ignorance/Abuse

- Do not take risks with anything with which you don’t have proper knowledge about it

- Ask if you are unsure about anything as your instructor for right answer

- Misuse of equipment in a misguided spirit of fun may cause severe injury or death

- Cylinders of any compressed gas or liquid can become bombs if wrongly treated

- Electricity can cause severe sock or it can also kill

- The materials like rubber, flour, sugar, metal and cork can produce violent explosions if mixed with air or oxygen

- Some rare-earth metals will spontaneously ignite if sprinkled in the air

- A soldering iron can initiate an explosion with volatile liquids like high-octane petrol

FAQs

What is the most important aspect of welding safety?

The most important aspect of welding safety is to protect the welder from the potential hazards of the process, such as hazardous fumes, sparks, and intense heat.

What are some general safe for practice to know as a welder?

Some general safe practices for welders include:

- Wearing appropriate personal protective equipment, including a welding helmet, gloves, and protective clothing

- Ensuring proper ventilation to remove hazardous fumes

- Maintaining a clean and well-organized work area

- Following proper procedures for storing and handling flammable materials

- Never welding in areas where there may be flammable gases or liquids

- Being aware of the fire hazards associated with welding, and having fire extinguishers readily available

- Following proper procedures for shutting down and disconnecting equipment before performing maintenance or repairs

- Keeping a safe distance from the welding arc to prevent burns, and avoiding looking directly at the arc

- Avoiding welding on painted or coated surfaces, as the heat can cause toxic fumes

- Avoiding improper use of welding equipment

What are the significant of safety precaution in welding?

The significance of safety precautions in welding is to protect the welder from the potential hazards of the process, such as hazardous fumes, sparks, and intense heat, as well as to prevent fires and explosions.

What is the most important safety rule in resistance welding?

The most important safety rule in resistance welding is to follow the manufacturer’s instructions and guidelines for the specific equipment being used.

What are the proper safety equipment used in welding?

Proper safety equipment used in welding includes a welding helmet, gloves, protective clothing, safety glasses, and ear protection.

How do we prevent failure of accidents in welding?

To prevent failures and accidents in welding, it is important to follow safe practices, such as proper ventilation, wearing appropriate personal protective equipment, and following proper procedures for shutting down and disconnecting equipment before performing maintenance or repairs.

Is our welding safety important in our workplace?

Welding safety is extremely important in the workplace, as it protects the welder and others in the vicinity from potential hazards and injuries. Employers have a responsibility to provide a safe working environment for their employees and to ensure that they are properly trained in the safe use of welding equipment.

Conclusion

In conclusion, welding is a process that can be dangerous if proper safety precautions are not taken. Welders and those working in the vicinity of welding operations must be aware of the potential hazards, including exposure to hazardous fumes and sparks, as well as the risk of burns and eye damage. It is important for employers to provide a safe working environment for their employees and to ensure that they are properly trained in the safe use of welding equipment. Some general safe practices for welders include wearing appropriate personal protective equipment, ensuring proper ventilation, maintaining a clean and well-organized work area, and following proper procedures for storing and handling flammable materials. By following these guidelines and best practices, we can ensure that welding operations are safe and that those working in the field are protected from potential hazards.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders