How to Set MIG Welding Amperage and Wire Feed Speed Metal Inert Gas (MIG) welding is a cornerstone in fabrication, manufacturing, and repair industries. Its efficiency and relative ease of learning make it popular, but achieving consistently high-quality welds hinges on understanding and controlling its core parameters. Among the most …

Read More »6GR Welding Position

What is 6GR Welding Position? Welding positions are classifications that describe the angle and orientation of the welded parts during the weld.The 6GR welding position is one of the most advanced and difficult positions out there. It’s used to simulate real-life situations where space is tight, movement is limited, and …

Read More »ASME B16.25

Introduction to ASME B16.25 – Buttwelding End Standards In the world of industrial welding, maintaining uniformity, precision, and safety is crucial. ASME B16.25 is one such standard that governs the preparation of buttwelding ends on piping components. But what exactly does this standard cover, and why is it important? Let’s …

Read More »2G 2F Welding Position

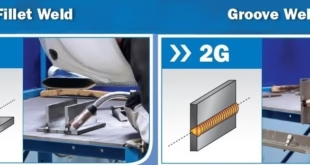

2G 2F Welding Position – A Complete Guide Welding is an essential process in manufacturing, construction, and various industries. One crucial aspect of welding is understanding different welding positions, as they determine the difficulty, technique, and outcome of the weld. Among these positions, the 2G and 2F welding positions are …

Read More »ASME BPVC Section IX

Introduction to ASME BPVC Section IX The ASME BPVC (Boiler and Pressure Vessel Code) is one of the most recognized standards in the world for ensuring the safety, reliability, and efficiency of pressure vessels, boilers, and piping systems. Among its multiple sections, Section IX holds particular significance as it governs …

Read More »Can You Weld Cast Iron?

Can You Weld Cast Iron? Cast iron is a material commonly found in various industries due to its strength, durability, and versatility. It’s used in everything from engine blocks to cookware. However, when it comes to repairing or modifying cast iron components, many people wonder, “Can you weld cast iron?” …

Read More »TIG Root Pass Techniques

TIG Root Pass Techniques When it comes to welding, particularly TIG welding, the term “root pass” is frequently used, especially for thicker materials. The root pass sets the foundation for the remaining welds, making it a crucial first step in the multi-pass welding process. But what exactly is a root …

Read More »2T vs. 4T vs. S4T in Welding

Understanding 2T/4T/S4T Features in Welding: Differences and Usage Introduction Welding technology has evolved significantly, offering diverse modes that optimize precision, efficiency, and ease of use. Selecting the right mode is crucial to ensure effective welding outcomes. Among the various features available, the 2T, 4T, and S4T modes are widely used …

Read More »Joint Preparation

Proper Joint Preparation for Welding Welding might seem straightforward, but the quality of your weld largely depends on the preparation work done beforehand. Proper joint preparation is crucial for creating strong, durable welds that can stand the test of time and stress. So, why is it so important? Think of …

Read More »ISO 14174

ISO 14174 – Fluxes for Submerged Arc Welding Submerged Arc Welding (SAW) is a highly efficient automated welding process suited for high-speed welding of metals. Fluxes play a crucial role in this process, shielding the weld area from atmospheric gases and influencing the mechanical and chemical properties of the weld. …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders