What Causes Welding Spatter? Welding spatter is caused by unstable molten metal droplets being ejected from the arc or weld pool. The instability arises from a combination of incorrect process parameters, consumable or base-metal contamination, poor shielding or gas flow, equipment faults, and operator technique. Fundamental physics of arc metal …

Read More »Porosity vs Blowholes

Porosity vs. Blowholes — A Complete Practical Guide for Welders and Inspectors Porosity and blowholes are two of the most common gas-related discontinuities you’ll encounter in welding and casting. On the surface they can look similar—small pits, cavities, or irregular hollows in the weld—but their origins, shapes, consequences, and fixes …

Read More »Hot Cracking

What Is Hot Cracking (Solidification Cracking)? Quick Definition and Why It Matters Hot cracking—also called solidification cracking—is a weld defect that forms while the weld metal is still hot and partly solid, when weak liquid films at grain boundaries cannot accommodate shrinkage and tensile strains, causing the solidifying weld to …

Read More »Acceptable Porosity

How Much Porosity Is Acceptable in a Weld? Porosity is like the tiny potholes of the welding world — small, hidden, and sometimes harmless, but in the wrong spot or quantity, they can cause catastrophic failure. So, how much porosity is too much? The answer isn’t a one-size-fits-all — it …

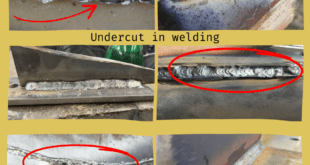

Read More »Acceptance Criteria for Undercut

Understanding Acceptable Welding Undercut and Its Acceptance Criteria Welding undercut is a groove melted into the base metal adjacent to the weld toe that isn’t filled with weld metal. While some degree of undercut may seem minor, excessive or poorly formed undercut can reduce fatigue life, create stress risers, and …

Read More »Rod Sticking

How to Prevent Welding Rod Sticking Definition and Explanation Welding rod sticking occurs when the electrode fuses slightly to the workpiece without establishing a stable arc. Instead of a clean ignition, the rod stops conducting properly and becomes part of the base metal until you yank it free. Arc Initiation …

Read More »How NOT to Stick Weld

How NOT to Stick Weld Mastering stick welding (Shielded Metal Arc Welding or SMAW) is as much about knowing how NOT to Stick Weld as it is about following the right steps. Many welders, especially beginners, unknowingly form bad habits that limit their weld quality, cause frustration, or even lead to …

Read More »Blowholes

Understanding Blowholes in Welding: Causes, Prevention, and Inspection In the world of welding, we encounter various challenges. Welding isn’t just about melting metal; it’s about creating strong, reliable joints that meet specific standards. However, imperfections known as welding defects can arise, which may compromise the integrity, strength, and appearance of …

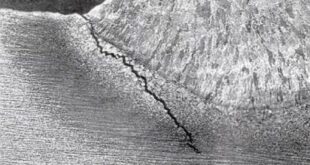

Read More »cast iron cracking

How to Avoid Cast Iron Cracking Why Cast Iron Cracks During Welding Welding cast iron is notoriously difficult due to its brittle nature and high carbon content. One of the biggest challenges welders face is cast iron cracking, which can occur before, during, or after welding. The primary culprit behind …

Read More »Anti-Spatter Spray

What is Anti-Spatter Spray? Does it Actually Work? Welding is an essential process in various industries, from automotive to construction. However, one of the most frustrating aspects of welding is dealing with spatter—those tiny molten metal droplets that stick to surfaces, causing defects and requiring extra cleanup. To combat this …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders