How to Deal With Weld Spatter In Stick Welding Welding can be an incredibly rewarding skill, but let’s face it—stick welding (also known as Shielded Metal Arc Welding or SMAW) can be messy. Spatter, those annoying metal droplets flying everywhere, can make an otherwise enjoyable job frustrating. But hey, don’t …

Read More »MIG Welding Mistakes

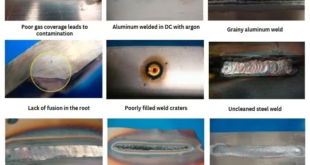

How NOT TO Weld | MIG Welding Mistakes Introduction MIG welding, or Metal Inert Gas welding, is a preferred method for joining metals due to its speed, efficiency, and ease of learning. Despite its popularity, MIG welding is susceptible to numerous common errors. These mistakes can result in weak welds, …

Read More »TIG Welding Problems

Common TIG Welding Problems and Their Solutions TIG welding, or Tungsten Inert Gas welding, is renowned for producing clean, precise, and high-quality welds. However, like any technical skill, it’s not without its challenges. In this article, we’ll dive into some common problems faced by TIG welders and explore practical solutions …

Read More »Prevent Arc Blow

How to Prevent Arc Blow in Stick Welding Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a versatile and widely used welding process. However, it comes with its own set of challenges, one of which is arc blow. If you’ve ever experienced an erratic arc, spatter, or uneven …

Read More »Chevron Cracking

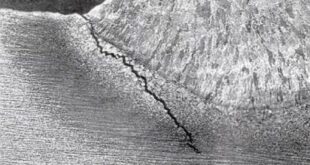

What is Chevron Cracking in Welding? Welding is a fascinating process that binds metals together, but like any technical procedure, it’s not without its challenges. One such challenge is Chevron Cracking, a defect that can compromise the strength and integrity of welded joints. But what exactly is Chevron Cracking, and how …

Read More »Sugaring In Stainless Steel

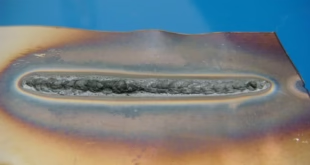

What Is Sugaring in Stainless Steel? What Does Sugaring Mean? Sugaring is a common term in welding that refers to the rough, oxidized surface that forms on stainless steel when it is exposed to oxygen during high-temperature processes, like welding. This grainy, sugar-like appearance usually forms on the underside of …

Read More »Weld Decay: Cause and Cure

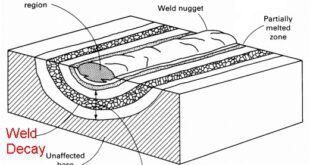

Weld Decay: Cause and Cure Weld decay is a critical issue in the welding world, especially for materials like stainless steel. This phenomenon occurs when welded areas lose their corrosion resistance, leading to potential structural failures. But why is this problem so significant? Weld decay isn’t just an occasional nuisance; …

Read More »Basics of Weld Corrosion

Basics of Weld Corrosion When dealing with welded structures, corrosion is a pervasive and often underestimated challenge. Welded joints are vital for maintaining the integrity of constructions, from pipelines to bridges. However, these joints are vulnerable to corrosion, which can weaken them over time, leading to costly repairs or even …

Read More »What is Smut in Aluminum Welding?

What is Smut in Aluminum Welding? Aluminum welding is widely valued for creating strong, lightweight, and corrosion-resistant joints. However, a significant welding defect known as “smut” can occur, compromising the weld’s aesthetic and mechanical integrity. Smut in welding is typically a blackened, sooty residue that accumulates on the weld surface, …

Read More »Poor Shielding Gas Coverage in Welding

Poor Shielding Gas Coverage in Welding Proper Shielding gas coverage plays a pivotal role in welding by protecting the weld pool from atmospheric contamination, which can ruin the quality and strength of the weld. It acts as a protective barrier, keeping out elements like oxygen and nitrogen that can cause …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders