Cold Cracking: Causes and Cures

Introduction

Welding is more than just joining metals—it’s about creating structures that can endure stress and last a long time. However, welding comes with challenges, and one of the most critical is cold cracking. Known as the “silent destroyer” of welds, cold cracking can occur hours or even days after the welding process, making it unpredictable and costly. Understanding what causes this phenomenon and how to prevent it is essential for welders, engineers, and anyone working with metals.

What is Cold Cracking?

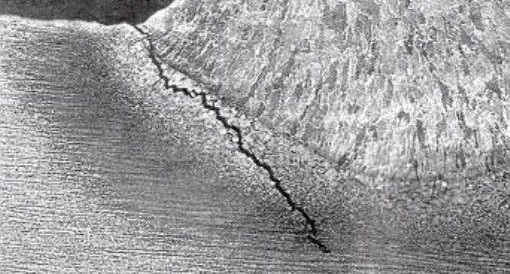

Cold cracking, also referred to as delayed cracking, is a type of weld defect that appears after the weld has cooled. It typically occurs within the heat-affected zone (HAZ) or the weld metal itself. Unlike hot cracking, which develops during the solidification of the weld at high temperatures, cold cracking manifests when the weld reaches room temperature or even later.

What makes cold cracking particularly problematic is its delayed nature, which can lead to unnoticed structural weaknesses in critical applications like bridges, pipelines, and heavy machinery. By the time the crack becomes visible, the weld may already be compromised, leading to expensive repairs or even structural failure.

Causes of Cold Cracking

Cold cracking is the result of multiple interacting factors. To fully grasp how to prevent it, you need to understand its primary causes:

Hydrogen Embrittlement

Hydrogen is often called the “enemy of welds” because it can infiltrate the weld pool from unexpected sources, such as:

- Moisture on the welding surface or electrodes.

- Lubricants, oils, or rust on the base material.

- Atmospheric humidity if the work area isn’t adequately controlled.

Once hydrogen enters the weld, it diffuses into the material’s microstructure, weakening it and making it brittle. The combination of brittleness and stress provides the perfect conditions for cracks to form.

Residual Stresses

When metals heat and cool during welding, they expand and contract. This expansion and contraction create residual stresses within the weld and surrounding areas. Picture bending a metal strip repeatedly—it eventually snaps due to built-up tension. Similarly, residual stress in a weld can reach a breaking point, especially when combined with other factors like hydrogen embrittlement.

Brittle Microstructure

The cooling rate of the weld plays a critical role in determining the microstructure of the material. If the weld cools too quickly or if improper materials are used, it can form a brittle microstructure. A brittle microstructure lacks the flexibility to handle stress, making it more prone to cracking under pressure.

Factors That Increase the Risk of Cold Cracking

Beyond the primary causes, several risk factors make cold cracking more likely. Understanding these helps in minimizing potential issues.

Material Susceptibility

Some materials are more vulnerable to cold cracking than others. For example:

- High-carbon steels: These steels are prone to hardening, making them more susceptible to brittle microstructures.

- Alloying elements: Manganese, chromium, and other elements can increase the hardenability of steel, amplifying the risk of cold cracking.

Environmental Factors

Environmental conditions play a significant role. Cold weather slows down the cooling rate of the weld, while high humidity can introduce more hydrogen into the weld. These conditions create the perfect storm for cold cracking, especially in outdoor welding applications.

Welding Parameters

The way you weld matters. For instance:

- High heat input can lead to larger heat-affected zones, increasing residual stresses.

- Rapid welding speeds may leave insufficient time for hydrogen to dissipate.

- Incorrect electrode choice can add unnecessary hydrogen to the weld.

How to Detect Cold Cracking

Detecting cold cracking is crucial because early identification can save both time and money. However, this is no easy task since cold cracks often form below the surface or appear after some delay.

Visual Inspection

Surface cracks can often be detected through careful visual inspection. This method is simple and cost-effective, but it only works for surface-level defects.

Nondestructive Testing (NDT) Methods

For deeper or internal cracks, advanced techniques like the following are necessary:

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal cracks.

- Magnetic Particle Testing (MT): Reveals cracks in ferromagnetic materials by highlighting interruptions in magnetic fields.

- Radiographic Testing (RT): Employs X-rays or gamma rays to visualize cracks.

Timing of Inspection

Cold cracking doesn’t appear immediately, so it’s essential to inspect the weld several hours or even days after completion. Delayed inspections give enough time for cracks to develop and be detected before putting the weld into service.

Cures for Cold Cracking

If cold cracking does occur, there are remedies that can mitigate the damage or prevent it from happening again.

Preheating

Preheating the base material before welding slows the cooling rate, which prevents brittle microstructures from forming. It also allows hydrogen to diffuse out of the weld zone before it becomes trapped. Preheating temperatures depend on the material:

- For high-strength steels: 100-300°C is common.

- For low-carbon steels: Lower preheating temperatures, around 50-100°C, may suffice.

Post-Weld Heat Treatment (PWHT)

PWHT is a controlled heating process applied after welding to relieve residual stresses and reduce hardness in the weld and HAZ. This step is especially critical for materials prone to cold cracking, such as high-strength steels.

Controlling Hydrogen

Reducing hydrogen content is one of the most effective ways to combat cold cracking. Measures include:

- Storing consumables in dry conditions.

- Baking electrodes to remove moisture.

- Cleaning the base material thoroughly before welding.

Best Practices to Prevent Cold Cracking

Prevention is always better than cure. Here are the most effective practices:

- Material Selection: Choose materials with lower susceptibility to cracking, such as low-carbon steels or alloys specifically designed for welding applications.

- Welding Techniques: Maintain optimal welding parameters, including proper heat input and travel speed.

- Equipment Maintenance: Regularly inspect and maintain welding machines, electrodes, and consumables to avoid introducing hydrogen or defects.

FAQs

What is the difference between cold cracking and hot cracking?

Cold cracking occurs after the weld has cooled, while hot cracking happens during the welding process when the metal is still molten.

How does preheating prevent cold cracking?

Preheating slows down the cooling rate, allowing hydrogen to diffuse out and reducing the formation of brittle microstructures.

Can low-hydrogen electrodes eliminate cold cracking?

They significantly reduce the risk by minimizing hydrogen content, but other factors like stress and brittle microstructures must also be addressed.

Is cold cracking more common in certain climates?

Yes, cold and humid environments increase the risk by introducing more hydrogen and amplifying residual stresses.

What should I do if I detect cold cracking after welding?

Immediately stop using the structure, assess the extent of the damage, and carry out necessary repairs. Implement preventive measures for future welds.

Conclusion

Cold cracking is a complex issue that can cause significant problems if not addressed. By understanding its causes, recognizing the risk factors, and applying prevention techniques, you can greatly reduce its occurrence. Remember, success in welding isn’t just about creating strong welds—it’s about ensuring those welds stand the test of time.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders