Common Stainless Steel Welding Defects

Introduction to Stainless Steel Welding

Stainless steel is a widely used material across industries because of its corrosion resistance, durability, and versatility. It’s found in everything from kitchen appliances to automotive parts, but the challenge comes when it needs to be welded. Stainless steel requires precise control and a specific approach to avoid defects. Unlike carbon steel, which can be more forgiving during welding, stainless steel is sensitive to heat, and small mistakes can lead to significant problems.

Welding stainless steel involves fusing two or more pieces using high heat. However, if not done correctly, the weld can weaken the material, compromising its structural integrity. Whether you are welding stainless steel in construction, manufacturing, or repair work, ensuring that the welds are defect-free is crucial to achieving long-lasting and reliable results.

Why Stainless Steel Welding Defects Occur

Defects in stainless steel welding don’t just happen by accident. Various factors can contribute to these flaws. One of the most common reasons is improper preparation of the base material. If the surface is dirty, greasy, or rusty, it can lead to contamination during the welding process. Even a small amount of moisture can create issues such as porosity.

Another factor is the welding technique itself. Stainless steel has different thermal properties compared to other metals. It expands and contracts differently, and without the right control of heat, the material can warp or crack. Environmental factors such as high humidity or improper ventilation can also exacerbate the problem. Defects occur when the balance of temperature, materials, and technique isn’t maintained properly.

Types of Common Stainless Steel Welding Defects

There are several types of defects that can occur during the welding of stainless steel. Each one affects the weld’s integrity in a different way, making it crucial for welders to understand how they form and how to prevent them. The most common defects include:

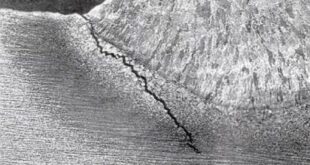

- Cracking: Cracks can severely weaken a weld, making it prone to failure under stress. Cracking can occur during or after welding and can be influenced by high thermal stress or improper cooling rates.

- Porosity: Porosity refers to small gas pockets trapped in the weld metal. These voids reduce the density and strength of the weld, leading to potential failures.

- Incomplete Fusion: This defect occurs when the weld metal doesn’t fully bond with the base material, leading to weak points where the two pieces of metal are not properly joined.

- Undercutting: Undercutting is when the weld erodes the base material, leaving a groove along the edges. This can compromise the strength of the weld and the overall structure.

- Weld Spatter: Spatter is the small droplets of molten metal that are thrown out of the weld pool during welding. While it doesn’t necessarily weaken the weld, it affects the appearance and can lead to inclusions.

- Lack of Penetration: This happens when the weld doesn’t fully penetrate the joint, leaving portions of the base metal unjoined. This reduces the strength of the welded joint and its load-bearing capacity.

Cracking in Stainless Steel Welding

Cracking is one of the most dangerous defects that can occur in stainless steel welding. There are two main types of cracking: hot cracking and cold cracking.

- Hot Cracking: Hot cracking happens during the solidification of the weld metal, when it is cooling down. This is usually due to the presence of impurities like sulfur or phosphorus in the weld. These impurities lower the melting point of certain areas, causing cracks to form as the metal solidifies. Hot cracking is often seen in high-temperature zones of the weld.

- Cold Cracking: Cold cracking occurs after the weld has cooled down, usually several hours or even days later. It is often caused by residual stress left in the metal after welding or by hydrogen that gets absorbed into the weld. Cold cracking is especially problematic because it can go unnoticed until the weld is put under stress.

Cracks can be difficult to detect and may lead to sudden failure under load. To prevent cracking, make sure you’re using the right filler materials and controlling the cooling rate carefully. Preheating the base material can also help to reduce thermal stress.

Porosity in Stainless Steel Welding

Porosity is a defect where gas pockets become trapped in the weld metal, leading to small voids or cavities. These gas pockets can significantly weaken the weld, especially if the porosity is widespread.

There are a few reasons why porosity occurs:

- Contaminants: Dirt, oil, or rust on the base material can introduce gases during welding. These gases can become trapped in the molten weld pool, forming voids as the metal cools.

- Improper Shielding Gas: Stainless steel welding often requires specific shielding gases to protect the weld from atmospheric contamination. If the shielding gas is incorrect or if there are leaks in the gas supply, air can get into the weld pool, causing porosity.

- Humidity and Moisture: Moisture from the environment or from poorly stored filler materials can vaporize during welding, creating gas bubbles in the weld.

To avoid porosity, always ensure that the base material and filler rods are clean and dry. Use the correct shielding gas and maintain a consistent flow throughout the welding process. If necessary, you can also adjust the welding parameters to reduce the chances of gas entrapment.

Incomplete Fusion and Its Consequences

Incomplete fusion happens when the weld metal does not properly fuse with the base material or with previous weld passes. This creates weak spots in the joint where the two materials aren’t fully connected. The consequences of incomplete fusion can be severe, as it reduces the overall strength of the weld and increases the risk of failure.

There are several causes of incomplete fusion:

- Insufficient Heat: If the heat input is too low, the weld metal won’t melt enough to fully bond with the base material. This is often due to incorrect welding parameters or an improper technique.

- Improper Welding Angle: The angle at which the electrode or torch is held can also affect fusion. If the angle is too steep or too shallow, it can result in incomplete fusion.

- Excessive Travel Speed: Moving too quickly across the weld can cause the weld pool to solidify before it has a chance to properly fuse with the base material.

To prevent incomplete fusion, make sure you’re using the correct heat settings and welding techniques. Slowing down your travel speed and ensuring a proper angle can help promote better fusion between the materials.

Undercutting: A Common Stainless Steel Welding Defect

Undercutting occurs when the weld erodes the base material, creating a groove along the edge of the weld. This weakens the joint and reduces the overall strength of the weld. Undercutting can be especially problematic in stainless steel welding because it can compromise the corrosion resistance of the material, leaving it more vulnerable to environmental damage.

Several factors can lead to undercutting:

- Excessive Heat Input: If too much heat is applied, the base material can melt away, leaving behind a groove.

- Improper Electrode Angle: The angle of the welding electrode can affect how the molten metal flows into the joint. A poor angle can lead to undercutting along the edges.

- Fast Travel Speed: Moving too quickly across the weld can also contribute to undercutting, as the weld pool doesn’t have enough time to fill in the groove created by the molten metal.

To avoid undercutting, reduce your heat input, adjust the angle of your electrode, and slow down your travel speed. This will allow the molten metal to properly fill in the joint without eroding the base material.

Effects of Weld Spatter

Weld spatter refers to small droplets of molten metal that are thrown out of the weld pool during welding. While spatter doesn’t usually weaken the weld, it can affect the appearance and create additional work, as it needs to be cleaned up afterward. In some cases, spatter can also lead to inclusions in the weld, reducing its quality.

Spatter is often caused by:

- High Current Settings: When the current is set too high, it can create excessive spatter as the molten metal is violently ejected from the weld pool.

- Incorrect Arc Length: Holding the welding torch too far from the workpiece can result in an unstable arc, leading to more spatter.

- Improper Shielding Gas: The wrong type of shielding gas or a poor gas flow can also cause spatter during stainless steel welding.

To reduce spatter, adjust the current settings and maintain a stable arc. Use the correct shielding gas and ensure that the gas flow is steady and consistent throughout the weld.

Lack of Penetration in Welds

Lack of penetration occurs when the weld metal does not fully penetrate the joint. This leaves parts of the base metal unjoined, weakening the overall structure and making it more prone to failure. Lack of penetration is a serious defect, as it reduces the weld’s load-bearing capacity and can lead to catastrophic failure under stress.

Causes of lack of penetration include:

- Low Heat Input: If the heat input is too low, the weld won’t penetrate deep enough into the joint.

- Poor Joint Design: A poorly designed joint can make it difficult for the weld to fully penetrate the base material.

- Incorrect Technique: In some cases, the welding technique may not allow for full penetration, especially if the torch angle or travel speed is incorrect.

To ensure proper penetration, increase the heat input, adjust your welding technique, and make sure the joint design allows for full access to the base material.

How to Prevent Stainless Steel Welding Defects

Preventing welding defects requires careful attention to detail before, during, and after the welding process. Understanding the potential causes of these defects can guide you in avoiding them and producing high-quality welds. Here’s how you can prevent some of the common defects:

- Material Preparation: Thoroughly clean the base metal to remove any contaminants, such as oil, grease, or rust. Even small particles can lead to porosity or weak spots in the weld.

- Use the Correct Filler Material: Using the right filler metal that matches the composition of the base material helps ensure a strong, defect-free weld.

- Control Heat Input: Stainless steel is highly sensitive to heat. Using the appropriate amount of heat—neither too high nor too low—helps prevent defects like cracking, warping, and lack of penetration.

- Proper Shielding Gas: Stainless steel welding requires specific shielding gases, often a mix of argon with helium or CO2. This protects the weld from contamination by the surrounding air.

- Monitor Welding Parameters: Set your machine to the correct voltage, amperage, and travel speed based on the thickness of the material and the type of stainless steel you are welding.

Identify and Repair Stainless Steel Welding Defects

Sometimes, defects occur despite the best preventive measures. Identifying them early through inspection can prevent serious problems down the line. Here are a few common methods for identifying welding defects:

- Visual Inspection: This is the simplest form of inspection, where you can visually assess the weld for surface defects like undercutting, spatter, or incomplete fusion. It’s often the first step in the quality control process.

- Radiographic Testing (X-rays): This method is used to identify internal defects such as porosity or cracks that aren’t visible on the surface. X-rays can reveal the internal structure of the weld and show any gaps, voids, or inclusions.

- Ultrasonic Testing (UT): Ultrasonic testing uses high-frequency sound waves to detect imperfections within the weld. It’s a highly accurate method for identifying internal defects and determining the overall quality of the weld.

- Magnetic Particle Testing: This method is used to detect surface and slightly subsurface defects. It’s commonly used for identifying cracks or incomplete fusion.

When defects are identified, they must be repaired before the part or structure is put into service. Repair methods depend on the type of defect:

- Grinding and Rewelding: For surface defects like undercutting or incomplete fusion, the affected area can be ground down and rewelded.

- Filling Porosity: If porosity is detected, the defective section can often be rewelded with improved shielding gas flow to prevent further gas entrapment.

- Post-Weld Heat Treatment: This process can be used to relieve stresses in the weld and reduce the chances of cracking. It can also improve the weld’s toughness and ductility.

Proper inspection and repair ensure that defects are eliminated before they can compromise the integrity of the welded structure.

FAQs

What causes cracking in stainless steel welds?

Cracking in stainless steel welds is often caused by excessive heat input, improper cooling rates, or residual stress in the metal. Hot cracking occurs during solidification, while cold cracking can occur later due to hydrogen absorption or stress.

How can I prevent porosity in stainless steel welding?

To prevent porosity, ensure that the base material is clean and dry, use the correct shielding gas, and avoid moisture contamination in the welding environment. Proper gas flow and consistent welding parameters can also reduce the risk of gas entrapment.

Why does undercutting occur, and how can I avoid it?

Undercutting happens when the base material is eroded due to excessive heat input or an improper welding angle. To avoid it, reduce heat input, adjust your electrode angle, and slow down your travel speed to allow the molten metal to fill the joint properly.

What is the best method for detecting internal welding defects?

Radiographic testing (X-rays) and ultrasonic testing are the most effective methods for detecting internal defects such as porosity, cracks, or incomplete fusion. These methods provide a detailed view of the weld’s internal structure.

How can I repair a weld with incomplete fusion?

Incomplete fusion can often be repaired by grinding down the affected area and rewelding it with proper heat input and technique. It’s essential to ensure that the weld metal fully bonds with the base material during the repair.

Conclusion

Welding stainless steel requires careful attention to detail to avoid defects that can compromise the strength and durability of the weld. From cracking to porosity and incomplete fusion, each defect weakens the weld in different ways. By understanding the causes of these defects and taking preventive steps, such as controlling heat input and ensuring proper material preparation, you can produce high-quality, defect-free welds.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders