FCAW vs GMAW

FCAW vs GMAW

Table of Contents

ToggleIntroduction

When it comes to welding, two of the most commonly discussed methods are Flux-Cored Arc Welding (FCAW) and Gas Metal Arc Welding (GMAW). Understanding the differences between these two techniques is crucial for anyone involved in welding, whether you’re a beginner or an experienced professional. This article aims to provide a comprehensive comparison of FCAW and GMAW, highlighting their unique characteristics, advantages, disadvantages, applications, costs, skill requirements, safety considerations, and environmental impacts. By the end of this article, you’ll have a clear understanding of which welding method might be best suited for your specific needs.

Understanding FCAW (Flux-Cored Arc Welding)

What is FCAW?

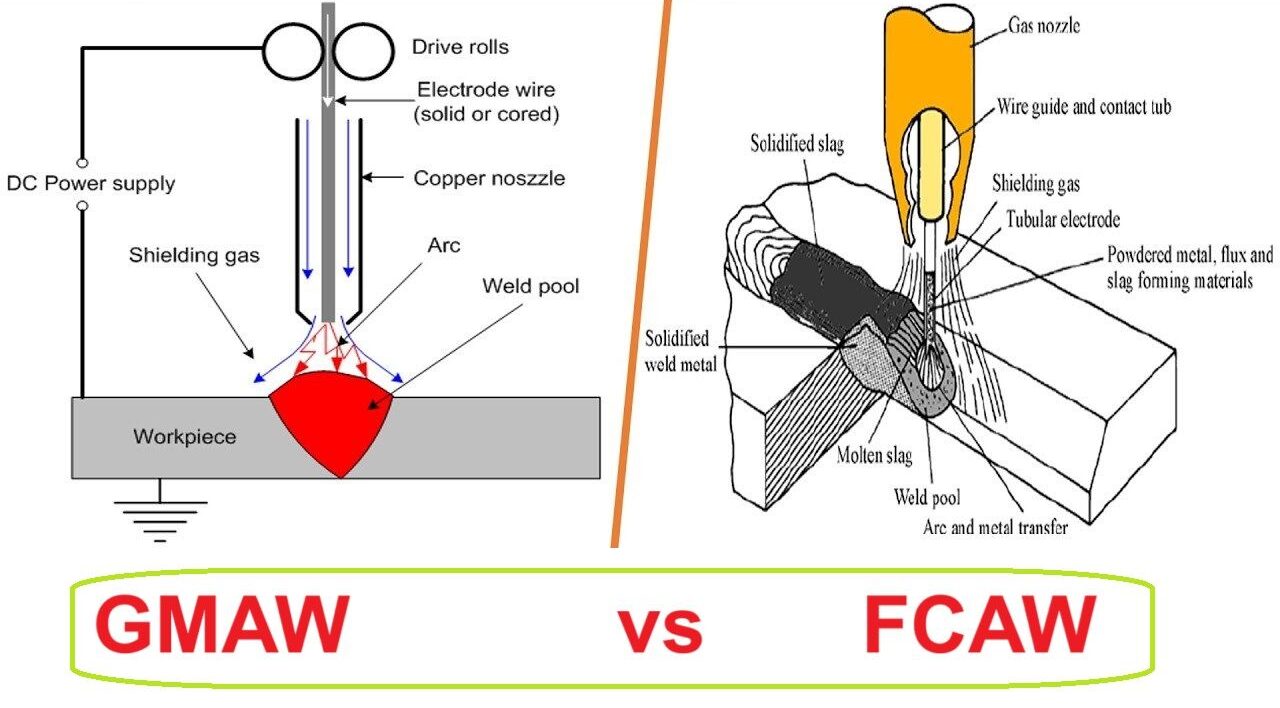

Flux-Cored Arc Welding, or FCAW, is a semi-automatic or automatic welding process that involves a continuously fed consumable electrode containing a flux core. This flux core generates protective gases and slag as the weld is laid down, which shields the weld pool from contamination.

Types of FCAW

Self-Shielded FCAW

Self-Shielded FCAW relies on the flux core of the wire to produce the necessary shielding gas. This makes it ideal for outdoor welding where wind might disperse external shielding gases.

Gas-Shielded FCAW

Gas-Shielded FCAW, on the other hand, uses an external shielding gas in addition to the flux core. This method is typically used in controlled environments and offers cleaner welds compared to self-shielded FCAW.

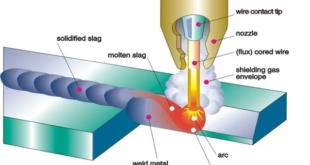

How FCAW Works

In FCAW, the electrode wire is fed through a welding gun, where it makes contact with the workpiece and creates an electric arc. The heat generated by the arc melts the wire and the base metal, forming a molten weld pool. The flux core within the wire releases gases and forms a slag that covers and protects the weld as it cools.

Understanding GMAW (Gas Metal Arc Welding)

What is GMAW?

Gas Metal Arc Welding, commonly known as MIG (Metal Inert Gas) welding, uses a continuous solid wire electrode fed through a welding gun. The process relies on an external shielding gas to protect the weld pool from atmospheric contamination.

Types of GMAW

Short Circuit Transfer

In short circuit transfer, the wire touches the workpiece and creates a short circuit, which generates heat and melts the wire. This method is suitable for thin materials.

Globular Transfer

Globular transfer involves the wire melting and forming large droplets that fall onto the workpiece. This method can be spattery and is less controlled.

Spray Transfer

Spray transfer creates a stable arc with small, consistent droplets transferring from the wire to the workpiece. It’s ideal for thick materials and provides high-quality welds.

Pulsed Spray Transfer

Pulsed spray transfer alternates between high and low current, allowing for better control over the heat input and reducing spatter. This technique is versatile and can be used on a variety of materials and thicknesses.

How GMAW Works

In GMAW, the wire electrode is continuously fed through the welding gun while an external shielding gas flows around the arc. The electric arc melts the wire and the base material, creating a weld pool. The shielding gas protects the molten pool from oxidation and contamination.

Advantages and Disadvantages

Advantages of FCAW

High Deposition RatesFCAW is known for its high deposition rates, making it efficient for welding thick materials.

Suitability for Outdoor Welding

Self-Shielded FCAW is less affected by wind, making it ideal for outdoor applications where maintaining a shielding gas might be challenging.

Versatility with Thick Materials

FCAW excels in welding thick sections of metal, providing strong and durable welds.

Lower Sensitivity to Contaminants

The flux core in FCAW helps in dealing with rust, mill scale, and other contaminants on the base metal, ensuring a cleaner weld.

Advantages of GMAW

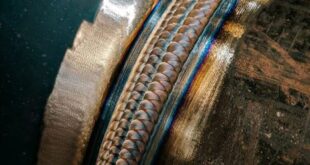

High Weld Quality

GMAW produces high-quality welds with minimal spatter, making it suitable for precision applications.

Ease of Automation

The continuous wire feed and the use of shielding gas make GMAW easier to automate, improving consistency and productivity in industrial applications.

Lower Fume Emission

GMAW generates fewer fumes compared to FCAW, creating a safer working environment.

Better Control and Precision

With various transfer modes available, GMAW offers better control over the welding process, allowing for precise and clean welds.

Disadvantages of FCAW

Higher Levels of Smoke and Fumes

FCAW generates significant amounts of smoke and fumes, necessitating proper ventilation and respiratory protection.

Requirement for Slag Removal

After welding with FCAW, slag must be chipped away from the weld, adding an extra step to the process.

Limited to Ferrous Metals

FCAW is generally limited to welding ferrous metals, which can restrict its use in some industries.

Disadvantages of GMAW

Shielding Gas Sensitivity to Wind

GMAW’s reliance on shielding gas makes it unsuitable for outdoor welding where wind can disperse the gas and compromise weld quality.

Higher Equipment Costs

The initial setup and equipment costs for GMAW can be higher compared to FCAW, especially when considering the need for gas cylinders and regulators.

Limited to Indoor or Controlled Environments

GMAW is best suited for indoor or controlled environments to ensure the integrity of the shielding gas.

Applications of FCAW/GMAW

Applications of FCAW

Construction Industry

FCAW is widely used in construction for structural steel welding due to its high deposition rates and suitability for thick materials.

Shipbuilding

The shipbuilding industry benefits from FCAW’s ability to weld thick sections and its performance in outdoor environments.

FCAW is ideal for manufacturing heavy equipment, providing strong welds for robust structures.

Applications of GMAW

Automotive Industry

GMAW is extensively used in the automotive industry for its precision and ability to weld thin materials without distortion.

Aerospace Industry

The aerospace industry relies on GMAW for its high-quality, precise welds and the ability to automate the welding process.

Fabrication of Metal Structures

GMAW is used in the fabrication of metal structures where high weld quality and precision are paramount.

Cost Considerations

Initial Setup Costs

FCAW generally has lower initial setup costs due to the simpler equipment required. GMAW, however, requires more expensive equipment, including gas cylinders and regulators.

Operational Costs

The operational costs of FCAW can be lower since it doesn’t always require external shielding gas. GMAW’s operational costs can be higher due to the need for continuous gas supply.

Maintenance Costs

Both FCAW and GMAW require regular maintenance, but GMAW equipment, being more complex, might incur higher maintenance costs.Read our Article on Estimating weld cost.

Skill Level and Training

Training Requirements for FCAW

FCAW typically requires less training compared to GMAW, making it accessible for beginners.

Training Requirements for GMAW

GMAW requires more extensive training due to the need to manage the shielding gas and the variety of transfer modes.

Ease of Learning and Mastering Each Technique

While both techniques have a learning curve, GMAW’s additional variables can make it more challenging to master compared to FCAW.

Choosing the Right Welding Technique

Factors to Consider

When choosing between FCAW and GMAW, consider factors such as the working environment, material thickness, and desired weld quality.

Application-Specific Recommendations

For outdoor and heavy-duty applications, FCAW might be more suitable. For precision and indoor welding, GMAW could be the better choice.

Personal Preferences and Experience

Your personal experience and comfort level with each technique should also influence your decision. Practical trials and training can help determine which method suits you best.

FAQs

What is the main difference between FCAW and GMAW?

The main difference lies in the shielding method. FCAW uses a flux core to generate protective gases, while GMAW relies on external shielding gas.

Which welding method is more cost-effective?

FCAW generally has lower initial setup and operational costs, but the choice depends on specific application requirements and long-term use.

Can FCAW be used for thin materials?

FCAW is better suited for thicker materials. For thin materials, GMAW is typically preferred due to its precision and lower heat input.

Is GMAW suitable for outdoor welding?

GMAW is not ideal for outdoor welding as the shielding gas can be dispersed by wind. FCAW, particularly self-shielded FCAW, is better for outdoor conditions.

What are the best practices for ensuring safety in welding?

Always use appropriate PPE, ensure proper ventilation, regularly inspect equipment, and follow safety protocols to minimize risks associated with welding.

Conclusion

Both FCAW and GMAW offer unique advantages and disadvantages. FCAW is well-suited for outdoor, heavy-duty welding with less concern for contaminants, while GMAW provides high-quality, precise welds suitable for automation and indoor environments. By understanding the characteristics of each method, you can make an informed decision on which welding technique best fits your needs.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders