Internal Welding Defects

Welding is a critical process in various industries, ensuring the structural integrity of assembled components. However, even in the hands of skilled welders, internal welding defects can compromise the quality of the welds, leading to potential hazards and failures.

Introduction

In the realm of welding, understanding internal defects is paramount to achieving durable and reliable welded joints. This article delves into the intricate world of internal welding defects, shedding light on their types, causes, detection methods, and preventive measures.

Importance of Weld Quality

Weld quality is not just a matter of aesthetics; it’s a crucial factor in determining the longevity and reliability of structures. Poor weld quality can result in catastrophic consequences, making it imperative to address and rectify internal welding defects.

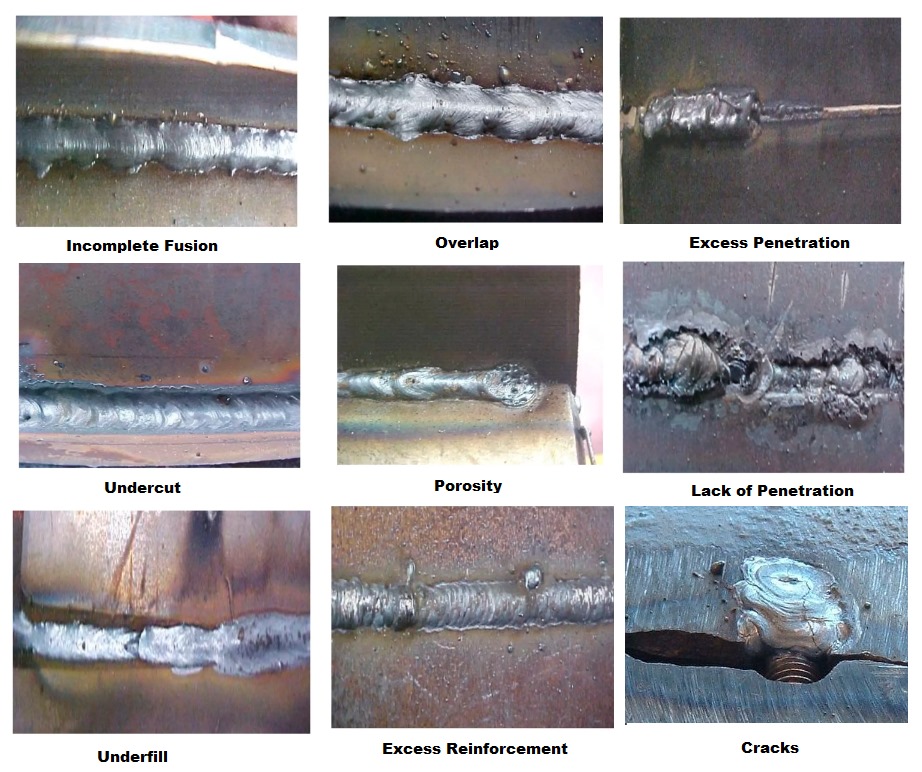

Common Types of Internal Welding Defects

Porosity

Porosity is a common internal welding defect characterized by the presence of air pockets within the weld metal. This can weaken the weld and compromise its structural integrity.

Slag Inclusions

Inclusions refer to foreign materials trapped in the weld metal, such as slag or oxides. These can act as stress concentrators, leading to weld failure over time.

Lack of Fusion

Lack of fusion occurs when there is incomplete bonding between the weld metal and the base material. This results in weakened joints susceptible to fractures.

Causes of Internal Welding Defects

Poor Welding Technique

Inadequate welding techniques, such as incorrect heat settings or improper electrode manipulation, can contribute to the formation of internal defects.

Contaminated Welding Materials

The use of contaminated welding materials introduces impurities into the weld, fostering the development of defects.

Inadequate Pre-weld Cleaning

Insufficient cleaning of the base materials before welding can leave contaminants, creating a breeding ground for defects.

Detection Methods

Visual Inspection

Visual inspection is the most straightforward method, involving a thorough examination of the weld for any visible defects.

Non-Destructive Testing (NDT)

NDT techniques, including ultrasonic testing and magnetic particle inspection, provide deeper insights into the internal structure of welds without causing damage.

Radiographic Testing

Radiographic testing uses X-rays or gamma rays to capture images of the internal weld structure, revealing defects that may be invisible to the naked eye.

Impact on Structural Integrity

Internal welding defects can compromise the structural integrity of welded joints, leading to premature failure and safety hazards.

Preventive Measures

Proper Training and Certification

Ensuring welders are adequately trained and certified helps mitigate the risk of defects resulting from poor technique.

Quality Control Measures

Implementing stringent quality control measures throughout the welding process helps identify and rectify defects promptly.

Adequate Welding Procedures

Following established welding procedures, including proper material preparation and cleaning, significantly reduces the likelihood of defects.

Industry Standards and Regulations

Welding Codes and Standards

Adhering to industry-specific welding codes and standards ensures that welds meet the required quality and safety criteria.

Regulatory Compliance

Complying with regulatory standards and guidelines is essential to guarantee the integrity of welded structures.

Advancements in Welding Technology

Automated Welding Processes

Automation in welding processes, such as robotic welding, minimizes human error and enhances the precision of welds.

Robotics in Welding

Robotic welding systems offer increased efficiency and consistency, reducing the likelihood of defects.

Future Trends

Artificial Intelligence in Weld Inspection

The integration of artificial intelligence in weld inspection is poised to revolutionize defect detection, providing faster and more accurate assessments.

Sustainable Welding Practices

The future of welding emphasizes sustainability, with eco-friendly practices and materials gaining prominence.

The Role of Skilled Welders

Training and Development

Continuous training and professional development empower welders to stay updated on the latest techniques and technologies.

Continuous Learning

The welding industry evolves, and continuous learning is essential for welders to adapt to new challenges and advancements.

FAQs

Can internal welding defects be completely eliminated?

While complete elimination is challenging, rigorous quality control measures significantly reduce the occurrence of internal defects.

How often should weld inspections be conducted?

Regular weld inspections, both visual and non-destructive, should be conducted as per industry standards and project requirements.

Are automated welding processes more reliable than manual welding?

Automated processes, when correctly implemented, offer higher reliability and consistency compared to manual welding.

What role does government regulation play in welding standards?

Government regulations set the minimum standards for welding, ensuring safety and quality across industries.

Is artificial intelligence the future of weld inspection?

Yes, AI in weld inspection is poised to revolutionize the speed and accuracy of defect detection in the welding industry.

Conclusion

In conclusion, understanding and addressing internal welding defects are paramount for ensuring the longevity and safety of welded structures. By implementing preventive measures, staying informed about industry advancements, and prioritizing the role of skilled welders, we can forge a future where welding defects are minimized.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders