Orbital Welding Techniques

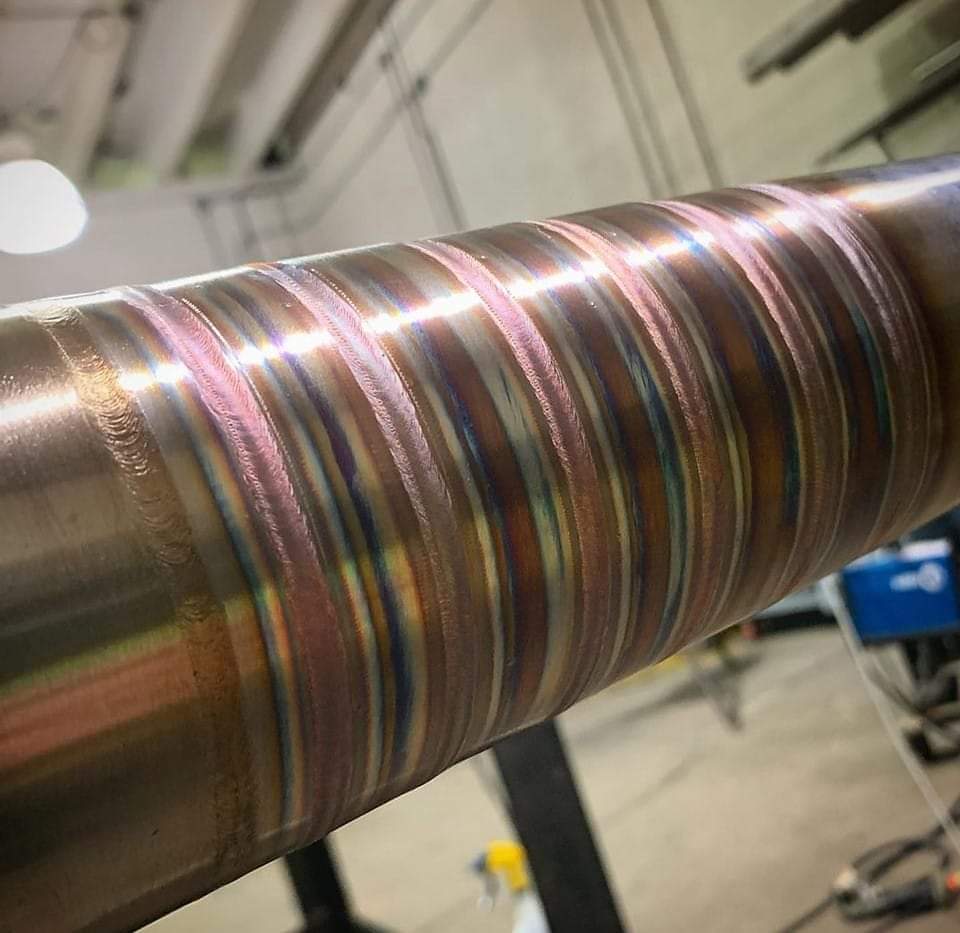

Orbital welding is a specialized welding process that involves the rotation of a welding electrode around the workpiece. This technique is highly effective for joining pipes and tubes in a variety of applications, particularly in industries that require precision, such as aerospace, pharmaceuticals, and nuclear power. As technology advances, orbital welding has become an essential method for ensuring the integrity and quality of welded joints in critical applications.

In this comprehensive guide, we’ll delve into the principles of orbital welding, its advantages, common applications, and best practices for implementing this innovative welding technique. By understanding the intricacies of orbital welding, you can make informed decisions about its application in your projects.

Table of Contents

ToggleUnderstanding Orbital Welding

Orbital welding combines the benefits of traditional welding methods with automated systems to create high-quality, precise welds. The process typically uses a tungsten electrode, which rotates around the workpiece, forming a consistent and controlled weld pool.

How Orbital Welding Works

- Setup:

The workpiece, usually a pipe or tube, is clamped in place. The orbital welding machine is set up with the appropriate parameters, including welding speed, arc length, and shielding gas flow. - Electrode Rotation:

As the welding machine begins operation, the tungsten electrode rotates around the circumference of the workpiece. This rotation allows for uniform heating and weld bead formation. - Welding Process:

The process typically involves a combination of heat generated by the arc and the shielding of the weld pool using an inert gas, such as argon. This shielding prevents contamination and ensures high weld quality. - Cooling and Inspection:

Once the welding cycle is complete, the weld is allowed to cool. After cooling, inspection and testing are conducted to verify the quality and integrity of the weld.

Advantages of Orbital Welding

Orbital welding offers numerous benefits, making it a preferred choice in many industries. Here are some key advantages:

- Precision and Consistency:

The automated nature of orbital welding allows for precise control over the welding parameters, resulting in consistent and high-quality welds. This is particularly important in critical applications where weld integrity is paramount. - Reduced Human Error:

By automating the welding process, orbital welding minimizes the potential for human error. This results in fewer defects and a higher level of quality assurance. - Improved Speed and Efficiency:

Orbital welding is typically faster than traditional welding methods due to its automated processes. This increased efficiency can lead to significant time savings on large projects. - Versatility:

Orbital welding can be applied to a variety of materials, including stainless steel, aluminum, and titanium. It is effective for welding thin-walled tubes and pipes, making it suitable for various industries. - Better Weld Quality:

The controlled environment and consistent heat application lead to superior weld quality. Orbital welds are often free from defects such as porosity and lack of fusion.

Common Applications of Orbital Welding

Orbital welding is widely used in several industries, including:

- Aerospace:

The aerospace industry requires high-quality welds to ensure safety and reliability. Orbital welding is used for joining components in aircraft and spacecraft, where precision is critical. - Pharmaceuticals:

In the pharmaceutical sector, orbital welding is employed for fabricating equipment and piping systems used in drug manufacturing. The high-quality welds produced by this technique help maintain the integrity of sterile environments. - Nuclear Power:

The nuclear industry relies on orbital welding for critical applications involving piping systems and pressure vessels. The precision and reliability of orbital welding are essential in this high-stakes environment. - Food and Beverage:

Orbital welding is used to construct piping systems in food and beverage processing. The clean, high-quality welds produced ensure that contamination is minimized, maintaining product safety. - Oil and Gas:

In the oil and gas industry, orbital welding is utilized for welding pipelines and other components that require high strength and durability in harsh environments.

Best Practices for Orbital Welding

To achieve optimal results with orbital welding, it is essential to follow best practices. Here are some key considerations:

- Proper Equipment Setup:

Ensure that the orbital welding machine is set up correctly, including the selection of the appropriate electrode, shielding gas, and welding parameters. Refer to the manufacturer’s guidelines for optimal settings. - Material Preparation:

Properly prepare the workpieces by cleaning the surfaces to remove contaminants. Ensure that the edges are aligned and fitted tightly to promote a good weld. - Calibration and Testing:

Regularly calibrate the welding machine and conduct test welds to verify the settings. This helps to identify any potential issues before commencing with production welds. - Monitor Parameters:

Continuously monitor welding parameters during the process to ensure consistency. This includes tracking the welding speed, arc length, and gas flow rates. - Post-Weld Inspection:

Conduct thorough inspections of the welds to identify any defects or areas of concern. Non-destructive testing methods such as ultrasonic testing or radiographic inspection can be employed for this purpose.

Conclusion

Orbital welding is a highly effective technique that combines precision, efficiency, and versatility. By understanding its principles, advantages, and best practices, you can leverage this innovative method for your welding projects. Whether in aerospace, pharmaceuticals, or oil and gas, orbital welding is transforming the way welds are performed, ensuring high-quality and reliable joints in critical applications. Embrace the benefits of orbital welding, and elevate your welding processes to meet the demands of modern industry.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders