Purge Welding vs. Non-Purge Welding

Introduction

Definition of purge welding

Purge welding is a welding technique that involves creating a protective gas atmosphere around the weld zone during the welding process. This is typically achieved by introducing an inert gas, such as argon, to displace the surrounding air. The purpose of purge welding is to prevent oxidation and contamination of the weld, ensuring a clean and high-quality weld joint. It is commonly used when welding materials that are sensitive to atmospheric gases, such as stainless steel, duplex stainless steel, titanium, and other reactive metals.

Definition of non-purge welding

Non-purge welding, also known as conventional or regular welding, refers to the welding process where a protective gas atmosphere is not actively maintained during the welding operation. Instead, the shielding gas used during welding, such as argon or a mixture of gases, provides some level of protection to the weld pool from atmospheric contamination. Non-purge welding is commonly used for materials that are less sensitive to oxidation and contamination, such as mild steel and carbon steel.

Importance of choosing the appropriate welding technique

Choosing the appropriate welding technique, whether it is purge welding or non-purge welding, is crucial for achieving the desired weld quality and meeting specific welding requirements. The welding technique can have a significant impact on the integrity, strength, and appearance of the weld joint. Factors such as the material being welded, the desired weld quality, the application of the welded structure, and the specific welding codes and standards need to be considered when selecting the welding technique.

Purge welding is particularly important when working with materials that are highly susceptible to oxidation and contamination. The presence of oxygen and nitrogen in the surrounding atmosphere can cause weld defects such as porosity, excessive oxidation, and reduced corrosion resistance in certain materials. By creating a controlled and oxygen-free environment, purge welding helps to eliminate these issues and ensures a high-quality weld with minimal defects.

Non-purge welding, on the other hand, is more suitable for materials that are less sensitive to atmospheric exposure. It can be a faster and more cost-effective welding technique, especially for applications where the weld quality requirements are not as stringent. However, it is essential to consider the potential risks of contamination and oxidation associated with non-purge welding, as these factors can affect the weld quality, structural integrity, and long-term performance of the welded components.

Purge Welding

Explanation of the purge welding process

Purge welding is a technique that involves creating a protective gas atmosphere around the weld zone to prevent oxidation and contamination during the welding process. The primary objective is to maintain a controlled environment that is free from atmospheric gases, particularly oxygen and nitrogen, which can adversely affect the quality and integrity of the weld.

Purpose and benefits of using a protective gas atmosphere

The purpose of using a protective gas atmosphere in purge welding is to create a barrier between the weld pool and the surrounding air. This serves several benefits:

- Prevents oxidation: Oxidation occurs when the molten metal reacts with oxygen, leading to the formation of oxides in the weld. By eliminating or minimizing the presence of oxygen, purge welding helps to prevent oxidation and maintain the corrosion resistance of the welded material.

- Reduces contamination: Atmospheric gases, such as nitrogen and moisture, can introduce impurities into the weld pool, leading to defects like porosity. By displacing the surrounding air with an inert gas, purge welding reduces the risk of contamination, resulting in a cleaner and more structurally sound weld.

- Improves weld quality: Purge welding contributes to the overall quality and integrity of the weld joint. It helps to achieve better fusion, improved mechanical properties, and enhanced aesthetics by minimizing defects and ensuring a consistent weld profile.

Materials that typically require purge welding

Purge welding is commonly used when working with materials that are highly susceptible to oxidation and contamination, including:

- Stainless steel: Stainless steel contains chromium, which provides its corrosion resistance. However, during welding, the presence of oxygen can lead to chromium depletion, compromising the material’s corrosion resistance. Purge welding helps to maintain the desired chromium levels, ensuring the integrity of the stainless steel welds.

- Duplex stainless steel: Duplex stainless steel possesses a mixed microstructure of austenite and ferrite, which provides excellent strength and corrosion resistance. However, maintaining the proper balance of these phases during welding is crucial. Purge welding is often necessary to prevent the formation of undesirable phases and maintain the desired properties.

- Reactive metals: Metals such as titanium, zirconium, and tantalum are highly reactive and can readily react with oxygen and nitrogen at elevated temperatures. Purge welding is essential to prevent contamination and preserve the unique properties of these metals.

Steps involved in the purge welding process

Purge welding typically involves the following steps:

- Creating a seal around the welding area: To establish a controlled environment, a seal is created around the weld joint using materials such as adhesive-backed tape, inflatable devices, or welding enclosures. This seal prevents the ingress of atmospheric gases into the welding zone.

- Introducing inert gas to displace surrounding air: Once the seal is in place, an inert gas, such as argon, is introduced into the sealed space to displace the surrounding air. The flow rate and pressure of the inert gas are controlled to create a positive pressure inside the sealed area, ensuring that no atmospheric gases enter the weld zone.

- Welding in a controlled atmosphere: With the inert gas purging the surrounding air, the welding operation can proceed in a controlled atmosphere. The welder performs the welding process, typically using techniques such as Tungsten Inert Gas (TIG) welding, which employs a non-consumable tungsten electrode and a separate filler material.

Advantages and disadvantages of purge welding

Advantages of purge welding include:

- Superior weld quality: Purge welding helps to minimize defects such as porosity, oxidation, and contamination, resulting in welds with improved mechanical properties and corrosion resistance.

- Consistent and aesthetic appearance: By reducing oxidation and maintaining the proper chemistry of the weld, purge welding produces welds with a consistent and aesthetically pleasing appearance, which is particularly important in applications where the welds are visible or require a high level of cosmetic appeal.

- Compliance with industry standards: Purge welding is often necessary to meet strict industry standards and regulatory requirements, especially in sectors such as aerospace, pharmaceuticals, and food processing. It ensures that welds adhere to the specified quality and integrity standards.

- Enhanced corrosion resistance: By minimizing oxidation and contamination, purge welding helps preserve the corrosion resistance of materials such as stainless steel and reactive metals, ensuring their long-term durability and performance in corrosive environments.

Disadvantages of purge welding include:

- Additional time and cost: Purge welding typically requires additional setup time and equipment compared to non-purge welding. The need for sealing devices, gas supply systems, and welding enclosures increases the overall cost of the welding operation.

- Complexity and expertise: Purge welding techniques require specialized knowledge and skills to create and maintain the controlled atmosphere during the welding process. Welders need to be proficient in handling the equipment and understanding the unique considerations of purge welding.

- Limitations in certain scenarios: Purge welding may not be feasible or practical in certain situations, such as when working with complex geometries, confined spaces, or areas with limited access. In such cases, non-purge welding techniques may be preferred.

Non-Purge Welding

Explanation of the non-purge welding process

Non-purge welding, also known as conventional or regular welding, is a welding technique where a protective gas atmosphere is not actively maintained during the welding operation. Instead, the shielding gas used during welding provides some level of protection to the weld pool from atmospheric contamination. The shielding gas, typically argon or a mixture of gases, forms a protective barrier around the weld, preventing the direct contact of atmospheric gases with the molten metal.

Use cases for non-purge welding

Non-purge welding is commonly employed in various applications where the weld quality requirements are less stringent or when specific conditions allow for the absence of a controlled protective gas atmosphere. Some use cases for non-purge welding include:

- Welding mild steel: Mild steel is less sensitive to oxidation compared to materials like stainless steel or reactive metals. Therefore, non-purge welding is often used for joining mild steel components in applications such as general fabrication, construction, and automotive industries.

- Coated or post-weld treated structures: Non-purge welding is suitable when the weld joint will undergo post-weld treatments, such as galvanizing, painting, or other protective coatings. These treatments can provide additional protection against corrosion, compensating for any potential oxidation during the welding process.

- Temporary or non-critical welds: Non-purge welding is often utilized for temporary welds or non-critical applications where the primary concern is achieving a functional weld rather than optimal weld quality. Examples include temporary fixturing, tack welding, or non-structural welds.

Materials suitable for non-purge welding

Non-purge welding is generally suitable for materials that are less sensitive to oxidation and contamination during the welding process. Some of the materials commonly welded using the non-purge technique include:

- Mild steel: Mild steel is a common material used in various industries, and non-purge welding is often applied for its joining due to its lower sensitivity to atmospheric exposure.

- Carbon steel: Carbon steel is another material that can be effectively welded using non-purge techniques, particularly when the carbon content is low to moderate.

- Low-alloy steels: Certain low-alloy steels, which contain additional alloying elements for improved mechanical properties, can also be welded using non-purge methods.

Shielding gas used in non-purge welding

In non-purge welding, the shielding gas serves the dual purpose of protecting the weld pool from atmospheric contamination and stabilizing the arc. Argon, often used as a standalone shielding gas, is commonly employed in non-purge welding due to its inertness and effectiveness in reducing atmospheric interactions with the molten metal. Additionally, mixtures of gases like argon and carbon dioxide (CO2) or argon and oxygen (O2) can be used depending on the specific requirements of the welding process.

Advantages and disadvantages of non-purge welding

Advantages of non-purge welding include:

- Simplicity and cost-effectiveness: Non-purge welding is generally simpler and less time-consuming compared to purge welding. It eliminates the need for creating a sealed environment and introducing inert gases, resulting in reduced setup time and lower costs.

- Time efficiency: Non-purge welding allows for faster welding operations since there is no waiting time for purging and setting up the controlled atmosphere.

- Versatility: Non-purge welding can be applied to a wide range of materials, including mild steel and carbon steel, making it a versatile technique for various applications.

Disadvantages of non-purge welding include:

- Increased risk of oxidation and contamination: Non-purge welding carries a higher risk of oxidation and contamination due to the absence of a controlled protective gas atmosphere. This can lead to weld defects such as porosity and reduced corrosion resistance, particularly in materials that are sensitive to atmospheric exposure, such as stainless steel and reactive metals.

- Compromised weld quality: Non-purge welding may result in lower weld quality compared to purge welding. The absence of a protective gas environment can lead to the formation of weld defects, including porosity, incomplete fusion, and excessive spatter. This can adversely affect the mechanical properties and overall integrity of the weld.

- Reduced corrosion resistance: Without the protection of a purge gas, non-purge welds are more susceptible to corrosion, especially in environments with high levels of moisture, chemicals, or corrosive substances. This can shorten the lifespan of the weld and compromise the overall durability of the welded structure.

- Limited application to sensitive materials: Non-purge welding is not suitable for certain materials that require a controlled atmosphere to maintain their properties. Reactive metals, stainless steel, and other alloys with high susceptibility to oxidation and contamination may necessitate the use of purge welding to ensure optimal results.

- Inadequate compliance with industry standards: Certain industries, such as aerospace, nuclear, or food processing, have strict quality and safety regulations that mandate the use of purge welding to achieve the desired weld integrity. Non-purge welding may not meet these stringent requirements, making it unsuitable for certain applications.

Despite these disadvantages, non-purge welding does offer some advantages, such as lower setup time and equipment costs compared to purge welding. It can be more suitable for materials that are less sensitive to oxidation and contamination, such as mild steel or carbon steel, and in scenarios where access to the weld joint is limited or complex. However, careful consideration of the trade-offs between weld quality, corrosion resistance, and compliance with industry standards is necessary when choosing non-purge welding as the preferred technique.

Comparison between Purge Welding and Non-Purge Welding

Weld quality and integrity:

Purge Welding:

Purge welding generally provides superior weld quality compared to non-purge welding. By creating a controlled atmosphere and minimizing oxidation and contamination, purge welding helps to produce welds with improved mechanical properties, enhanced corrosion resistance, and reduced defects such as porosity. The controlled environment ensures better fusion and a consistent weld profile, contributing to the overall integrity and durability of the weld joint.

Non-Purge Welding:

Non-purge welding, while capable of producing acceptable welds, may have lower overall weld quality compared to purge welding. The absence of a controlled atmosphere increases the risk of oxidation, contamination, and weld defects. The welds may exhibit higher porosity and reduced corrosion resistance, particularly in materials that are more sensitive to atmospheric exposure.

Contamination and oxidation risks

Purge Welding:

Purge welding significantly reduces the risks of contamination and oxidation during the welding process. By creating a controlled atmosphere with an inert gas, purge welding helps to prevent the ingress of atmospheric gases, such as oxygen and nitrogen, that can cause weld defects and compromise the quality of the weld joint. It ensures cleaner, defect-free welds with minimal porosity and improved resistance to corrosion.

Non-Purge Welding:

Non-purge welding carries a higher risk of contamination and oxidation compared to purge welding. While the shielding gas used in non-purge welding provides some level of protection, it may not be sufficient to completely eliminate the potential for contamination and oxidation. As a result, non-purge welds may be more prone to defects such as porosity and reduced corrosion resistance.

Material compatibility and sensitivity

Purge Welding:

Purge welding is particularly important when working with materials that are highly sensitive to oxidation and contamination. Stainless steel, duplex stainless steel, titanium, and other reactive metals are examples of materials that typically require purge welding. These materials are prone to degradation of their properties when exposed to atmospheric gases during welding. Purge welding helps to maintain the desired characteristics and integrity of these materials.

Non-Purge Welding:

Non-purge welding is more suitable for materials that are less sensitive to atmospheric exposure. Mild steel and carbon steel, for instance, are commonly welded using non-purge techniques as they have lower susceptibility to oxidation and contamination. While certain low-alloy steels can be welded without purging, materials that are highly reactive or prone to oxidation may still require purge welding for optimal results.

Applicability in different welding scenarios

Purge Welding:

Purge welding is commonly employed in critical applications where weld quality is paramount. Industries such as aerospace, pharmaceuticals, food processing, and oil and gas often require purge welding due to the high standards of weld integrity and the need to avoid contamination. It is particularly applicable in scenarios where the weld joint will be subjected to harsh environments, corrosive substances, or stringent regulatory requirements.

Non-Purge Welding:

Non-purge welding finds wider applicability in various industries and scenarios where the weld quality requirements are less stringent. It is often used in general fabrication, construction, automotive, and other non-critical applications. Non-purge welding can be suitable for temporary fixturing, tack welding, or non-structural welds. Additionally, it is commonly utilized when the weld joint will undergo post-weld treatments or coatings to provide additional protection against corrosion.

Cost considerations

Purge Welding:

Purge welding is generally more complex and time-consuming compared to non-purge welding. The process involves creating a sealed environment, introducing inert gases, and using specialized equipment and materials to maintain the controlled atmosphere. These additional steps and requirements can increase the cost of the welding operation. However, in industries where the weld quality and integrity are critical, the cost of purge welding is justified by the benefits it provides.

Non-Purge Welding:

Non-purge welding is simpler and more cost-effective compared to purge welding. It eliminates the need for creating a sealed environment and introducing inert gases, resulting in reduced setup time and lower equipment and material costs. This makes non-purge welding a preferred choice for applications where the weld quality requirements are less stringent or when cost efficiency is a priority.

Factors Influencing the Choice of Welding Technique

Material type and grade

The type and grade of the material being welded play a crucial role in determining the appropriate welding technique. Certain materials, such as stainless steel, duplex stainless steel, and reactive metals, are highly sensitive to oxidation and contamination, necessitating the use of purge welding. On the other hand, materials like mild steel and carbon steel are less prone to atmospheric exposure, making non-purge welding a viable option.

Welding specifications and requirements

The specific welding specifications and requirements set by the project, industry standards, or regulatory bodies are important factors in choosing the welding technique. The required weld quality, mechanical properties, and corrosion resistance can influence whether purge welding or non-purge welding is more suitable. Additionally, specific welding codes and standards may dictate the use of a particular technique for compliance purposes.

Weld joint location and accessibility

The location and accessibility of the weld joint also affect the choice of welding technique. In scenarios where creating a sealed environment for purge welding is challenging due to limited access or complex geometries, non-purge welding may be the more practical option. Non-purge welding can be performed in open-air environments, making it more adaptable to various joint configurations.

Time and cost constraints

Time and cost considerations often influence the choice of welding technique. Purge welding generally requires additional setup time and equipment, leading to higher costs compared to non-purge welding. If there are tight project deadlines or budget constraints, non-purge welding may be preferred as it is typically faster and more cost-effective.

Welder expertise and equipment availability

The expertise of the welder and the availability of appropriate equipment also influence the selection of the welding technique. Purge welding requires specialized knowledge and skills to create and maintain a controlled atmosphere. It also necessitates the availability of suitable sealing devices, inert gas supply systems, and welding enclosures. If the welder is more experienced and proficient in purge welding techniques and the necessary equipment is readily available, it may be the preferred choice.

FAQs

What is the purpose of purge welding?

The purpose of purge welding is to create a controlled atmosphere using an inert gas to minimize oxidation, contamination, and weld defects during the welding process.

Why purge stainless steel welding?

Purging is particularly important for stainless steel welding because stainless steel is highly sensitive to oxidation and contamination. Purging helps maintain the desired properties and integrity of the stainless steel weld by preventing the formation of chromium carbides and reducing the risk of weld decay.

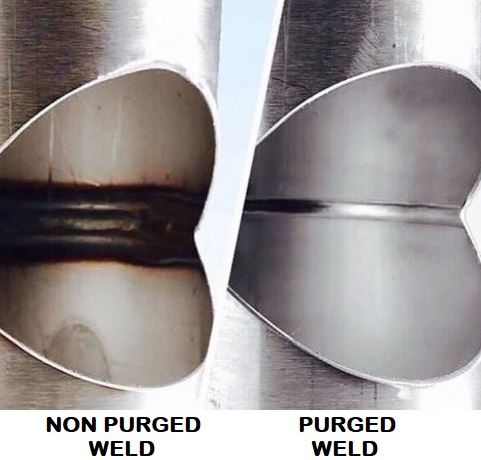

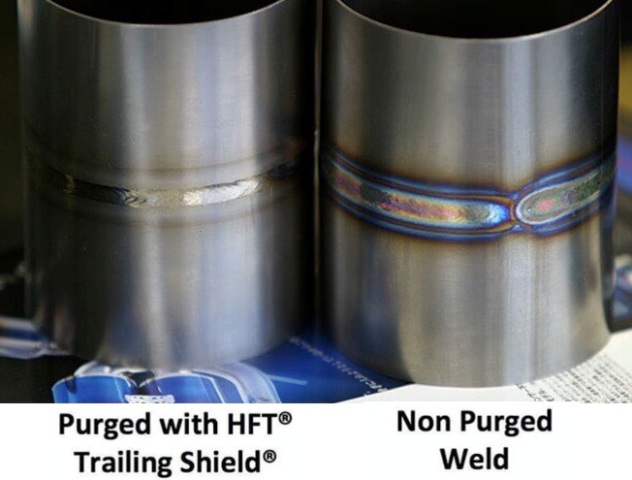

What happens to the weld when the pipe is not purged?

When a pipe is not purged during welding, it can result in the introduction of atmospheric gases, such as oxygen and nitrogen, into the weld zone. This can lead to weld defects such as porosity, reduced corrosion resistance, and decreased mechanical properties, compromising the quality and integrity of the weld joint.

Which material required purging?

Materials that are reactive or highly sensitive to oxidation and contamination, such as stainless steel, duplex stainless steel, and reactive metals like titanium, typically require purging during welding to ensure optimal weld quality and integrity.

What are the advantages of a purge?

The advantages of purge welding include improved weld quality, enhanced corrosion resistance, reduced porosity and defects, better mechanical properties, and the ability to meet stringent industry standards and regulatory requirements.

What is a purge process?

The purge process involves creating a sealed environment around the weld area and introducing an inert gas, such as argon, to displace the surrounding air. This controlled atmosphere helps prevent oxidation and contamination during welding.

How do you purge a weld?

To purge a weld, a seal is created around the weld area using materials such as tape, dams, or inflatable bladders. Then, an inert gas, such as argon, is introduced to displace the surrounding air and create a protective atmosphere.

How long to purge before welding?

The duration of purging before welding can vary depending on factors such as the size of the weldment, the material being welded, and the welding specifications. Typically, purging is done for a sufficient amount of time to ensure the displacement of air and achieve the desired level of oxygen concentration.

What is the formula for purge rate?

The formula for purge rate is typically calculated by considering factors such as the volume of the purge chamber, the desired oxygen concentration, and the flow rate of the purging gas.

Why argon gas is used in purging?

Argon gas is commonly used in purging due to its inert nature. It helps to displace oxygen and other atmospheric gases effectively, creating a protective environment during welding.

What gas is used to purge stainless steel?

For stainless steel welding, argon or a mixture of argon and helium is often used for purging. The choice of gas depends on the specific requirements of the welding process and the material being welded.

Can you weld stainless without purge?

While it is possible to weld stainless steel without purging, it may result in lower-quality welds with reduced corrosion resistance and increased risk of defects. Purging is generally recommended for optimal weld quality and to maintain the desired properties of stainless steel welds.

Conclusion

In conclusion, the choice between purge welding and non-purge welding depends on several factors that must be carefully considered. Purge welding, which involves creating a controlled atmosphere using inert gas, offers superior weld quality and integrity by minimizing oxidation and contamination. It is particularly suitable for materials highly sensitive to atmospheric exposure, such as stainless steel and reactive metals. On the other hand, non-purge welding, which relies on shielding gas, can be more cost-effective and versatile for materials that are less prone to oxidation, like mild steel and carbon steel.

The decision to use purge welding or non-purge welding relies on factors such as material type and grade, welding specifications and requirements, joint location and accessibility, time and cost constraints, as well as the expertise and equipment availability of the welder. Each technique has its advantages and disadvantages, and understanding these factors is crucial in ensuring optimal weld quality and meeting project needs.

Ultimately, choosing the appropriate welding technique is essential to achieve welds that meet the desired standards of quality, strength, and durability. Whether it is the need for a controlled atmosphere to prevent contamination and ensure corrosion resistance, or the flexibility and cost-effectiveness of non-purge welding, careful consideration of these factors will help in making an informed decision. By understanding the unique characteristics of purge welding and non-purge welding, welders and industry professionals can select the technique that best suits their specific requirements, ensuring successful welding outcomes in various applications.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders