Introduction

Resistance butt welding is a solid-state welding process wherein two metal workpieces are joined together by the application of heat and pressure. Unlike traditional fusion welding methods that involve melting the base metals, resistance butt welding relies on the generation of heat through electrical resistance at the interface of the workpieces. This process creates a strong and seamless bond between the materials, without the need for additional filler metals.

During resistance butt welding, the two workpieces are brought into contact, and an electrical current is passed through them. The resistance to the current flow at the interface generates heat, causing the metal to soften and fuse together under pressure. Once the desired weld is achieved, the current is discontinued, and the joint is allowed to cool, forming a metallurgical bond between the two pieces.

Understanding the Process

In this section, we’ll delve deeper into the intricacies of resistance butt welding, providing a comprehensive understanding of the process, its key components, and how it compares to other welding techniques.

Overview of the Resistance Butt Welding Process

Resistance butt welding, also known as resistance spot welding, is a solid-state welding process primarily used for joining two metal workpieces together. Unlike conventional fusion welding methods, which involve melting the base metals, resistance butt welding creates joints through the application of heat and pressure without melting the materials.

The process involves bringing the two workpieces into contact and passing an electrical current through them. The resistance to the current flow at the interface generates heat, softening the metal and causing it to fuse under pressure. Once the desired weld is achieved, the current is discontinued, and the joint is allowed to cool, forming a strong metallurgical bond between the two pieces.

Key Components Involved

Several key components are integral to the resistance butt welding process:

- Welding Electrodes: These are typically made of copper alloys and serve as the contact points through which the electrical current is passed onto the workpieces.

- Power Supply: The power supply delivers the electrical energy required to generate heat during the welding process. It must provide precise control over current, voltage, and timing parameters to ensure optimal weld quality.

- Clamping Mechanism: A clamping mechanism holds the workpieces firmly together during welding, ensuring proper alignment and contact between the surfaces to be joined.

- Control System: The control system regulates the welding parameters, such as current, voltage, and duration, based on the material type, thickness, and desired weld quality.

How Heat is Generated and Applied in Resistance Butt Welding

Heat is generated in resistance butt welding primarily through the resistance to electrical current flow at the interface of the workpieces. As the current passes through the metal, it encounters resistance, leading to the conversion of electrical energy into heat. This localized heating softens the material, allowing it to deform and fuse under pressure, forming a strong weld joint.

The amount of heat generated is determined by factors such as the magnitude of current, the duration of the welding cycle, and the electrical resistance of the materials being welded. Proper control and adjustment of these parameters are essential to achieving consistent and high-quality welds.

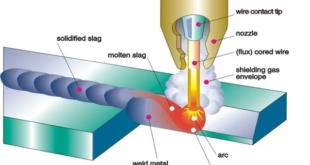

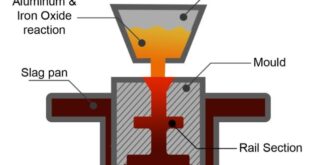

Comparison with Other Welding Techniques

Resistance butt welding offers several advantages over conventional fusion welding techniques such as MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding. Unlike fusion welding, which requires the use of filler metals and often results in distortion and porosity, resistance butt welding creates clean, precise welds without the need for additional materials. Additionally, resistance butt welding is well-suited for joining dissimilar metals and can produce joints with superior strength and integrity. Its efficiency, speed, and reliability make it a preferred choice for various industrial applications where high-quality welds are essential.

Metals Suitable for Resistance Butt Welding

Resistance butt welding is suitable for a wide range of metals, including:

Steel

Steel is one of the most commonly welded metals using resistance butt welding. Its versatility, strength, and availability make it an ideal choice for various industrial applications.

Aluminum

Aluminum exhibits excellent weldability with resistance butt welding, making it suitable for lightweight structures in automotive, aerospace, and marine applications.

Copper

Copper and its alloys are frequently welded using resistance butt welding due to their excellent electrical conductivity and corrosion resistance. These welds are widely used in electrical and electronic industries.

Techniques and Best Practices

In this section, we’ll explore the essential techniques and best practices for achieving optimal results in resistance butt welding. From preparation steps to troubleshooting tips, mastering these aspects is crucial for producing strong and durable welds.

Preparation Steps Before Welding

Before initiating the welding process, several preparation steps are essential to ensure the quality of the weld:

- Cleaning: Thoroughly clean the surfaces to be welded to remove any contaminants, such as dirt, oil, or rust, which can interfere with the welding process and weaken the weld joint.

- Alignment: Proper alignment of the workpieces is crucial to ensure uniform contact and consistent weld quality. Use alignment fixtures or clamps to hold the pieces in position securely.

- Surface Preparation: Ensure that the surfaces to be welded are flat and free of irregularities. Machining or grinding may be necessary to achieve the desired surface finish.

- Electrode Selection: Choose welding electrodes suitable for the materials being welded and the specific welding parameters. Proper electrode selection is critical for achieving optimal conductivity and heat distribution.

Selection of Appropriate Welding Parameters

The selection of welding parameters plays a significant role in determining the quality and integrity of the weld. Key parameters to consider include:

- Current: The magnitude of electrical current passing through the workpieces affects the amount of heat generated during welding. Proper current selection is essential for achieving the desired weld penetration and strength.

- Pressure: The amount of pressure applied to the workpieces influences the forging of the weld joint and the expulsion of any contaminants. Optimal pressure ensures adequate contact between the surfaces and promotes consistent fusion.

- Time: The duration of the welding cycle determines the heating and cooling phases of the process. Balancing the heating and cooling times is crucial for preventing overheating or insufficient fusion.

- Electrode Force: The force applied by the electrodes affects the compression of the workpieces during welding. Adjusting the electrode force ensures uniform contact and proper heat distribution.

Techniques for Achieving Strong and Durable Welds

To achieve strong and durable welds in resistance butt welding, consider the following techniques:

- Proper Sequence: Ensure that the welding sequence is consistent and follows a predefined procedure to maintain uniformity and integrity throughout the weld joint.

- Controlled Heat Input: Monitor and control the heat input during welding to prevent overheating or underheating, which can lead to defects such as burn-through or incomplete fusion.

- Post-Weld Treatment: Implement post-weld treatments such as stress relieving or annealing to improve the mechanical properties and durability of the weld joint.

- Quality Inspection: Conduct thorough inspections of the weld joint using non-destructive testing methods to detect any defects or inconsistencies and ensure compliance with quality standards.

Common Challenges and Troubleshooting Tips

Despite meticulous preparation and execution, resistance butt welding may encounter challenges that require troubleshooting:

- Poor Weld Quality: If the weld exhibits defects such as porosity, incomplete fusion, or cracking, review the welding parameters and adjust them accordingly to improve penetration and fusion.

- Electrode Wear: Excessive electrode wear can lead to inconsistent welds and reduced productivity. Regularly inspect and maintain the electrodes, and consider using electrode dressing techniques to prolong their lifespan.

- Material Incompatibility: When welding dissimilar materials, ensure compatibility and consider using intermediate materials or interlayers to promote bonding and prevent intermetallic reactions.

- Equipment Malfunction: Address any equipment malfunctions promptly, such as power supply issues or electrode misalignment, to prevent disruptions to the welding process.

Applications Across Industries

Resistance butt welding finds extensive use across a variety of industries due to its versatility, efficiency, and ability to produce high-quality welds. Let’s explore how this welding technique is applied in different sectors:

Automotive Industry

In the automotive industry, resistance butt welding plays a crucial role in the fabrication of various components and structures. It is commonly used for joining body panels, chassis components, exhaust systems, and other automotive parts. The high-speed production capabilities of resistance butt welding make it ideal for mass production environments, allowing automakers to achieve tight tolerances and consistent weld quality while maintaining cost-effectiveness.

Aerospace Industry

In the aerospace industry, where precision, strength, and reliability are paramount, resistance butt welding is employed in the manufacturing of aircraft structures, engine components, and aerospace assemblies. The ability of resistance butt welding to produce joints with minimal distortion and excellent mechanical properties makes it well-suited for critical applications in aerospace engineering. Additionally, its capability to join lightweight materials like aluminum and titanium contributes to the development of lightweight and fuel-efficient aircraft designs.

Construction Industry

In the construction industry, resistance butt welding is utilized for joining structural components, reinforcing bars, and metal frameworks. It enables the fabrication of sturdy and durable structures such as bridges, buildings, and infrastructure projects. Resistance butt welding offers advantages such as fast production rates, minimal material wastage, and superior joint strength, making it a preferred choice for construction applications where structural integrity is essential.

Electrical Industry

The electrical industry extensively utilizes resistance butt welding for joining copper and aluminum conductors in electrical cables, busbars, and electrical connections. Resistance butt welding provides a reliable and efficient method for creating secure electrical connections with minimal electrical resistance, ensuring optimal conductivity and performance. Its ability to produce joints with low electrical resistance and excellent mechanical strength makes it indispensable in the manufacturing of electrical components and systems.

Advantages and Benefits

Resistance butt welding offers numerous advantages and benefits that make it a preferred choice in various industries. Let’s explore some of these advantages:

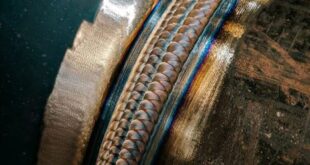

Superior Strength and Integrity of Welds

One of the primary advantages of resistance butt welding is its ability to produce welds with superior strength and integrity. The solid-state welding process creates a metallurgical bond between the workpieces, resulting in joints that exhibit high tensile strength and excellent fatigue resistance. This makes resistance butt welding suitable for applications requiring durable and long-lasting welds, such as automotive chassis, aerospace structures, and pressure vessels.

Cost-effectiveness Compared to Other Welding Methods

Resistance butt welding is highly cost-effective compared to other welding methods, particularly in high-volume production environments. The process requires minimal consumables, such as filler metals, reducing material costs. Additionally, the high speed and efficiency of resistance butt welding contribute to lower labor costs and increased productivity. The overall cost-effectiveness of resistance butt welding makes it an attractive option for manufacturers seeking to optimize their production processes while maintaining quality standards.

Efficiency and Speed of the Welding Process

Resistance butt welding is known for its efficiency and speed, making it suitable for high-volume manufacturing applications. The process involves rapid heating and forging of the workpieces, resulting in short cycle times and increased throughput. Additionally, resistance butt welding eliminates the need for preheating or post-weld heat treatment, further streamlining the production process. The efficiency and speed of resistance butt welding enable manufacturers to meet tight production deadlines and fulfill customer demands effectively.

Environmental Advantages (Minimal Fumes, Energy Efficiency, etc.)

Resistance butt welding offers several environmental advantages compared to traditional welding methods. The process generates minimal fumes and airborne contaminants, reducing air pollution and creating a safer working environment for operators. Additionally, resistance butt welding is energy-efficient, requiring lower power consumption compared to processes such as arc welding. The minimal environmental impact of resistance butt welding makes it an environmentally sustainable choice for manufacturers committed to reducing their carbon footprint and complying with environmental regulations.

FAQs

What are the main advantages of resistance butt welding?

Resistance butt welding offers advantages such as strength, durability, cost-effectiveness, and high production speed.

Which industries commonly use resistance butt welding?

Resistance butt welding is widely used in industries such as automotive, aerospace, construction, and electronics.

What factors affect the quality of resistance butt welds?

Factors such as material thickness, welding current, electrode pressure, and welding parameters influence the quality of resistance butt welds.

How can welding defects be prevented in resistance butt welding?

Welding defects can be prevented by optimizing process parameters, ensuring proper material preparation, and implementing quality control measures.

What are the safety precautions to follow during resistance butt welding?

Safety precautions include ventilation, use of protective gear, and regular maintenance of welding equipment to minimize risks to operators.

Conclusion

Resistance butt welding stands as a cornerstone of modern manufacturing, offering a reliable, efficient, and versatile welding technique with wide-ranging applications and benefits. Mastering this technique is not only essential for meeting the demands of today’s industries but also paves the way for innovation, growth, and sustainability in the future.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders