Resistance Welding – Which metal has excellent or poor weldability?

Introduction

Resistance welding is a joining process that involves the application of pressure and electric current to the metal area being welded, causing the metal to melt and fuse together. It is a commonly used welding process in various industries, including automotive, aerospace, and electronics, due to its ability to provide strong and reliable welds.

Selecting the appropriate welding process for different metals and alloys is critical to achieving optimal results in terms of weld quality, productivity, and cost-effectiveness. The ease of weldability and recommended welding methods vary depending on the specific properties of the metal or alloy being welded, such as its composition, thickness, and joint configuration.

Therefore, it is essential to have a guide that provides information on the ease of weldability and recommended welding methods for common metals and alloys in resistance welding. This guide can help welding professionals and manufacturers select the appropriate welding process for their specific applications, ensuring that they achieve the desired results and avoid issues such as weld defects, porosity, and cracking.

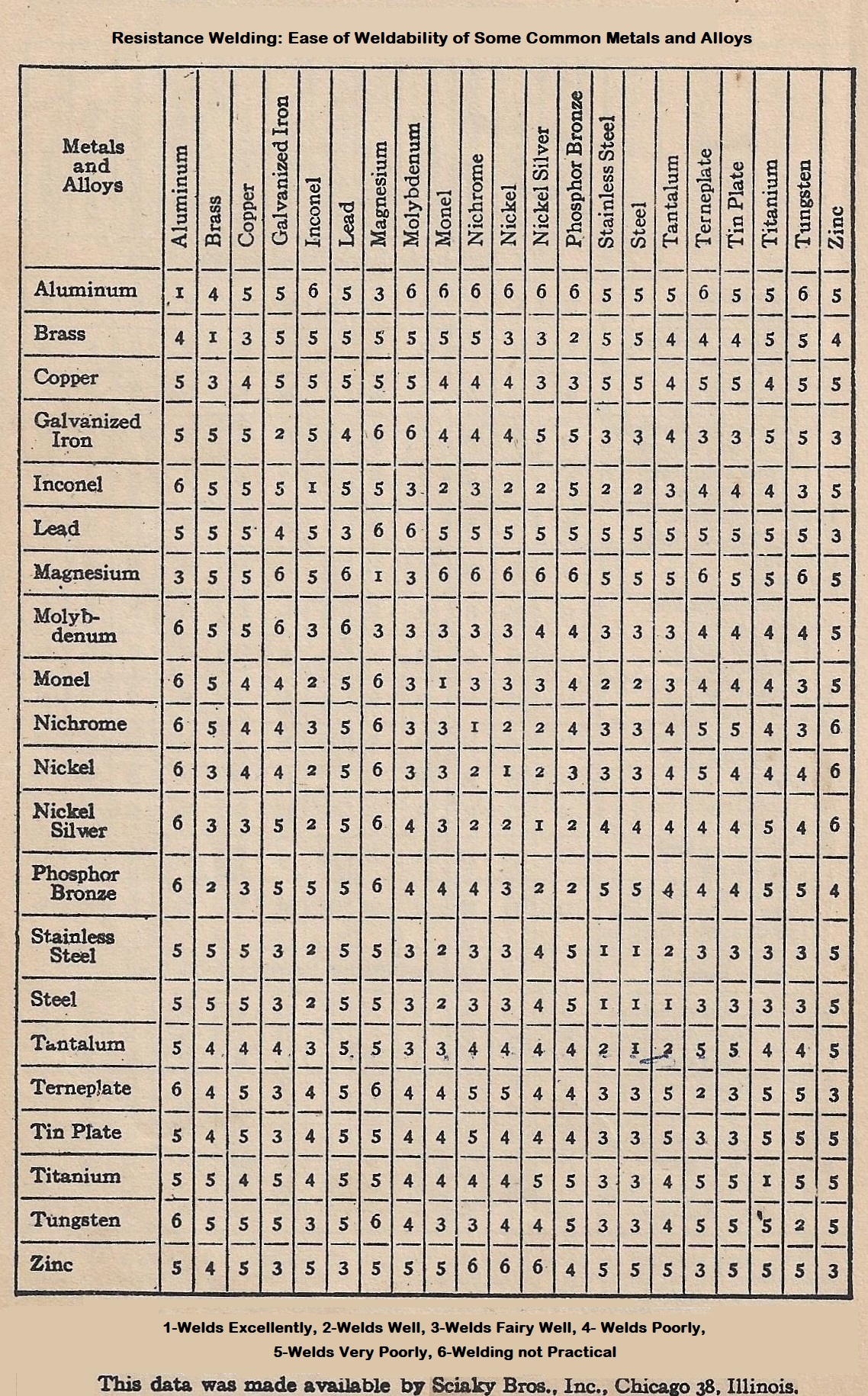

Ease of Weldability for Common Metals and Alloys

Resistance welding is a versatile joining process that can be applied to a wide range of metals and alloys. However, the ease of weldability varies depending on the specific properties of the metal or alloy being welded. The following are the ease of weldability for common metals and alloys in resistance welding:

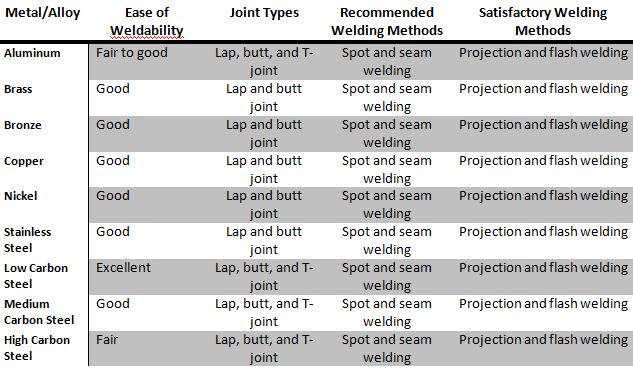

- Aluminum: Aluminum is relatively easy to weld, but its weldability depends on its alloy composition and thickness. Welding methods such as spot and seam welding are recommended for aluminum.

- Brass: Brass is considered easy to weld due to its low melting point and high thermal conductivity. Spot and seam welding are recommended for brass.

- Bronze: Bronze is also considered easy to weld due to its low melting point and high thermal conductivity. Spot and seam welding are recommended for bronze.

- Copper: Copper is considered easy to weld due to its high thermal conductivity. Spot and seam welding are recommended for copper.

- Nickel: Nickel is considered easy to weld due to its high melting point and ductility. Spot and seam welding are recommended for nickel.

- Stainless Steel: Stainless steel is relatively easy to weld, but its weldability depends on its alloy composition and thickness. Spot and seam welding are recommended for stainless steel.

- Low Carbon Steel: Low carbon steel is considered excellent in terms of weldability due to its low carbon content and high thermal conductivity. Spot and seam welding are recommended for low carbon steel.

- Medium Carbon Steel: Medium carbon steel is considered good in terms of weldability, but its weldability may be affected by its carbon content and alloy composition. Spot and seam welding are recommended for medium carbon steel.

- High Carbon Steel: High carbon steel is considered fair in terms of weldability due to its high carbon content and alloy composition. Spot and seam welding are recommended for high carbon steel.

Factors Affecting Ease of Weldability

The ease of weldability for different metals and alloys in resistance welding can be affected by several factors, including:

- Alloy composition

The composition of the metal or alloy being welded can affect its ease of weldability. Some alloys may require pre- and post-weld heat treatments to prevent cracking or distortion.

- Thickness

The thickness of the metal or alloy being welded can also affect its ease of weldability. Thicker materials may require higher current levels or longer welding times to achieve a proper weld.

- Joint configuration

The type of joint being welded can also affect the ease of weldability. Some joints may require specific welding methods to achieve proper fusion.

- Welding parameters

The welding parameters, such as current, voltage, and electrode force, can also affect the ease of weldability. Proper selection and adjustment of these parameters can ensure a quality weld.

The ease of weldability for common metals and alloys in resistance welding varies depending on their specific properties. Several factors can affect the ease of weldability, including alloy composition, thickness, joint configuration, and welding parameters. Welding professionals and manufacturers must consider these factors when selecting the appropriate welding process for their specific applications.

Welding Methods for Different Joint Types

Resistance welding offers several welding methods suitable for different joint types. The following are the recommended and satisfactory welding methods for different joint types:

Lap Joint

In a lap joint, two pieces of metal overlap. The recommended welding method for lap joints is spot welding.

Butt Joint

In a butt joint, two pieces of metal are placed end-to-end. The recommended welding methods for butt joints are spot welding and seam welding.

T-Joint

In a T-joint, two pieces of metal intersect at a right angle, forming a T-shape. The recommended welding methods for T-joints are spot welding, seam welding, and projection welding.

Spot Welding

Spot welding is a resistance welding method that involves applying electric current and pressure to the metal area being welded, causing it to melt and fuse together. It is commonly used in lap joints, T-joints, and other joint types where the thickness of the material being welded is less than 3mm.

Seam Welding

Seam welding is a resistance welding method that involves applying continuous electric current and pressure to the metal area being welded, causing it to melt and fuse together. It is commonly used in butt joints and other joint types where the thickness of the material being welded is more than 3mm.

Projection Welding

Projection welding is a resistance welding method that involves applying electric current and pressure to a small projection on one of the metal pieces being welded. The projection serves as a focal point for the welding current, causing the metal to melt and fuse together. It is commonly used in T-joints and other joint types where a precise location for the weld is required.

Flash Welding

Flash welding is a resistance welding method that involves applying high current and pressure to the metal area being welded, causing it to melt and fuse together. It is commonly used in butt joints and other joint types where high-quality welds are required.

Factors Affecting Recommended Welding Methods

Several factors can affect the recommended welding methods for different joint types in resistance welding, including:

- Joint type The type of joint being welded can affect the recommended welding method. Different welding methods may be recommended for lap joints, butt joints, and T-joints.

- Material thickness The thickness of the material being welded can affect the recommended welding method. Spot welding is commonly used for thinner materials, while seam welding is recommended for thicker materials.

- Material type The type of material being welded can affect the recommended welding method. Different welding methods may be recommended for different materials, such as stainless steel, aluminum, and low carbon steel.

- Weld quality requirements The quality requirements of the weld can affect the recommended welding method. For high-quality welds, flash welding may be recommended, while for lower quality welds, spot welding may be sufficient.

Considerations for Specific Applications

When selecting the appropriate welding method for a specific application, it is essential to consider several factors, including:

Alloy Composition

The composition of the metal or alloy being welded can affect the weldability and the recommended welding method. Some materials are more difficult to weld than others, and some welding methods are more suitable for certain alloys. Therefore, it is important to consider the alloy composition and select the appropriate welding method accordingly.

Thickness

The thickness of the material being welded can also affect the recommended welding method. Some welding methods, such as spot welding, are more suitable for thinner materials, while others, such as seam welding, are better for thicker materials.

Joint Configuration

The joint configuration, including the shape and size of the joint, can also affect the recommended welding method. Some welding methods, such as projection welding, are more suitable for T-joints, while others, such as seam welding, are better for butt joints.

Welding Specifications

Welding specifications, such as the required strength and quality of the weld, can also affect the recommended welding method. Some welding methods, such as flash welding, may produce stronger and higher-quality welds than others.

Consultation with Welding Experts

Finally, it is always advisable to consult with welding experts and professionals to ensure the appropriate welding method is selected for a specific application. Welding experts can provide valuable insights and recommendations based on their experience and expertise.

FAQs

Which metals have poor weldability and which metal has the best weldability?

Some metals that have poor weldability include cast iron, titanium, and certain high-strength steels. Generally, aluminum and certain types of stainless steel have good weldability.

What material is difficult to weld by resistance welding?

Materials that have poor electrical conductivity, such as high-strength steels, are difficult to weld by resistance welding.

What is resistance welding suitable for?

Resistance welding is suitable for joining metals with high electrical conductivity, such as copper and aluminum.

What causes poor weldability of aluminum?

The poor weldability of aluminum is due to its high thermal conductivity and oxide layer that forms on its surface.

What is poor welding?

Poor welding refers to the result of a welding process that produces a low-quality or defective joint between two pieces of metal.

Which materials are suitable for resistance welding?

Materials that have high electrical conductivity, such as copper and aluminum, are suitable for resistance welding.

What is the hardest material to weld?

Generally, materials that are difficult to weld include high-strength steels, titanium, and certain refractory metals.

What is the most difficult weld?

The most difficult weld depends on various factors, including the materials being joined, the welding process being used, and the complexity of the joint. However, generally speaking, welding dissimilar metals or thin materials can be challenging.

Conclusion

In conclusion, when selecting the appropriate welding method for a specific application, considerations such as alloy composition, thickness, joint configuration, welding specifications, and consultation with welding experts should be taken into account. By considering these factors, welding professionals and manufacturers can ensure the appropriate welding method is selected, resulting in high-quality and efficient welding processes.

In conclusion, selecting the appropriate welding process is crucial to achieving optimal results in welding applications. There are various welding processes available, each with its advantages and disadvantages, and selecting the right process can be the difference between a successful or failed welding application. Resistance welding, in particular, is a popular welding process due to its efficiency, speed, and ability to produce high-quality welds.

When selecting a welding process, it is important to consider the metal or alloy being welded, joint type, thickness, and welding specifications. These factors can affect the ease of weldability and recommended welding methods. Additionally, consultation with welding experts can provide valuable insights into selecting the appropriate welding process for a specific application.

The guide provides a comprehensive overview of the ease of weldability for common metals and alloys, recommended and satisfactory welding methods for different joint types, and considerations for specific applications. By following these guidelines, welding professionals and manufacturers can select the appropriate welding process for their applications, resulting in high-quality and efficient welding processes.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders