What is Narrow Gap Welding? Definition and Overview: Narrow gap welding (NGW) is a specialized technique tailored for welding thick materials by minimizing the width of the groove between the joint surfaces. This process significantly reduces the amount of filler material required and enhances efficiency. By creating a narrow groove, …

Read More »Boiler Welding Techniques

Boiler Welding Techniques – A Complete Guide for Professionals Boiler welding is a specialized craft essential to the structural integrity and performance of boilers. Boilers operate under high pressure and temperature, often containing volatile substances. Welding for boilers demands advanced skill and understanding to ensure joints can withstand extreme stresses …

Read More »Types of Welding And Their Uses

Different Types of Welding and What They Are Used For Welding is a critical process in various industries, used to join materials, primarily metals, by applying heat, pressure, or both. This versatile technique is vital in the construction of buildings, infrastructure, vehicles, machinery, and much more. While the basic principle …

Read More »How Robotic Technology is Transforming Welding

How Robotic Technology is Transforming Welding? The welding industry is experiencing a seismic shift as robotic technology takes center stage, revolutionizing how welding processes are carried out. Traditionally reliant on manual labor, welding is now integrating advanced robotics to enhance productivity, precision, and safety. This transformation is driven by the …

Read More »Eastwood Elite TIG 200 LCD Review

Eastwood Elite TIG 200 LCD: Unveiling the Welding Powerhouse Introduction Welding enthusiasts, both novices and seasoned professionals, are always on the lookout for a welding machine that strikes a perfect balance between features, performance, and affordability. In this comprehensive review, we dive into the intricacies of the Eastwood Elite TIG …

Read More »Tubular Cored Wire Welding

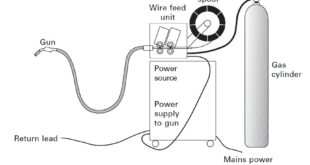

Tubular Cored Wire Welding Introduction The welding industry has witnessed significant advancements in technology, and one notable innovation that has gained prominence is Tubular Cored Wire Welding. This method represents a sophisticated approach to joining metals, offering distinct advantages over traditional welding techniques. Definition Tubular cored wire welding is a …

Read More »Sheet and Plate Metal Welding

Sheet and Plate Metal Welding Introduction Sheet and plate metal welding is a critical process in the realm of metalworking and manufacturing. It involves joining flat metal pieces together to create various structures and components, using various welding techniques. This article explores the fundamentals and significance of sheet and plate …

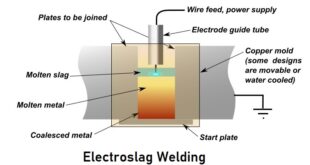

Read More »What is Electroslag Welding?

What is Electroslag Welding? Introduction Electroslag welding is a specialized welding process that offers numerous advantages in specific applications. In this comprehensive guide, we will delve into the intricacies of electroslag welding, exploring its definition, process, applications, benefits, limitations, and more. Whether you are a welding enthusiast, a professional welder, …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders