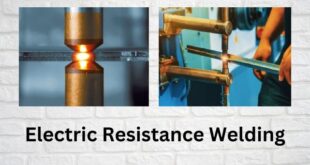

Introduction Resistance butt welding is a solid-state welding process wherein two metal workpieces are joined together by the application of heat and pressure. Unlike traditional fusion welding methods that involve melting the base metals, resistance butt welding relies on the generation of heat through electrical resistance at the interface of …

Read More »What is Flame Hardening?

A Comprehensive Overview, Process, and Benefits Introduction Flame hardening, also known as flame surface hardening or flame heating, is a heat treatment method used to increase the hardness and wear resistance of metal surfaces. It involves the localized heating of a metal component using a high-temperature flame, followed by rapid …

Read More »Tungsten Carbide Hardfacing and Welding

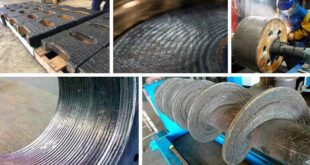

Tungsten Carbide Hardfacing and Welding Introduction The field of metallurgy and material science has witnessed remarkable advancements, and one such innovation that has garnered significant attention is Tungsten Carbide Hardfacing. This technique involves applying a layer of tungsten carbide, a robust and wear-resistant material, onto the surface of a substrate, …

Read More »Sheet and Plate Metal Welding

Sheet and Plate Metal Welding Introduction Sheet and plate metal welding is a critical process in the realm of metalworking and manufacturing. It involves joining flat metal pieces together to create various structures and components, using various welding techniques. This article explores the fundamentals and significance of sheet and plate …

Read More »Robotic Grinding and Sanding Automation

Robotic Grinding and Sanding Automation In today’s rapidly evolving industrial landscape, the term “automation” has become synonymous with efficiency, precision, and cost-effectiveness. Robotic Grinding and Sanding Automation is at the forefront of this automation revolution, offering a myriad of advantages to various industries. This article delves into the world of …

Read More »Thermographic Testing – NDT Inspection

Maximizing Quality: Comprehensive Guide Thermographic Testing for Welded Joints Thermographic Testing operates on the principle of detecting temperature variations. It utilizes an infrared camera to capture the heat patterns emitted by the surface of the welded joint. The underlying idea is simple: flaws or defects often generate distinct thermal signatures. …

Read More »Robotic Welding in the Automotive Industry: Revolutionizing Manufacturing Processes

Robotic Welding in the Automotive Industry In the fast-paced world of automotive manufacturing, innovation and efficiency are paramount. Robotic welding, a groundbreaking technological advancement, has emerged as a game-changer in the industry. This article delves into the transformative impact of robotic welding in the automotive sector, examining its benefits, applications, …

Read More »Mold Tool and Die Repair Welding

Mold Tool and Die Repair Welding Introduction Overview of mold tool and die repair welding Mold tool and die repair welding is a specialized process used to restore and repair damaged molds and dies used in various industries, such as manufacturing, automotive, and aerospace. Welding techniques are employed to fix …

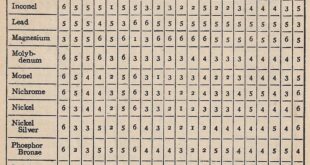

Read More »Resistance Welding – Which metal has excellent or poor weldability?

Resistance Welding – Which metal has excellent or poor weldability? Introduction Resistance welding is a joining process that involves the application of pressure and electric current to the metal area being welded, causing the metal to melt and fuse together. It is a commonly used welding process in various industries, …

Read More »How To Become CSWIP 3.1 Welding Inspector?

How To Become CSWIP 3.1 Welding Inspector? Introduction CSWIP 3.1 certification is a globally recognized certification scheme for welding inspectors developed by the Certification Scheme for Welding Inspection Personnel (CSWIP), which is a division of TWI Ltd. This certification is considered to be a standard for welding inspection and is …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders