Introduction Resistance butt welding is a solid-state welding process wherein two metal workpieces are joined together by the application of heat and pressure. Unlike traditional fusion welding methods that involve melting the base metals, resistance butt welding relies on the generation of heat through electrical resistance at the interface of …

Read More »Electrogas Welding

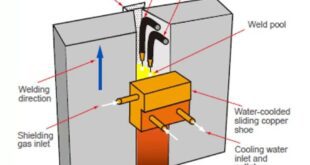

Electrogas Welding: Revolutionizing Industrial Welding Introduction Electrogas welding, also known as EGW, is a fusion welding process primarily used for thick materials, typically ranging from 1 inch to several inches in thickness. It involves the application of heat generated by electrical resistance to melt and join metals together, forming a …

Read More »Sheet and Plate Metal Welding

Sheet and Plate Metal Welding Introduction Sheet and plate metal welding is a critical process in the realm of metalworking and manufacturing. It involves joining flat metal pieces together to create various structures and components, using various welding techniques. This article explores the fundamentals and significance of sheet and plate …

Read More »Ten Signs You are Welding Correctly

Ten Signs You’re Welding Correctly Welding involves a lot of variables: different techniques, different metals, and different positions, to name just a few. But despite all that variety, your goal with any welding project — even with any single weld — is a reliable, safe weld that functions correctly. To …

Read More »What Is Hot Pressure Welding?

What Is Hot Pressure Welding? Introduction Welding is an important process used in various industries for joining materials. One of the most effective welding techniques is hot pressure welding, which involves the use of heat and pressure to join materials together. In this article, we will explore the basics of …

Read More »MIG VS TIG VS Stick vs Flux Core

MIG VS TIG VS Stick vs Flux Core: A Comprehensive Comparison Introduction In the world of welding, there are several different processes to choose from, each with its own advantages and disadvantages. This article will explore four popular welding methods: MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), Stick, and …

Read More »Welding Non-Ferrous Metals

Welding Non-Ferrous Metals: Techniques, Applications, and Challenges Introduction Welding is a critical manufacturing process that joins materials together to create strong and durable structures. While welding is often associated with ferrous metals like steel and iron, it is equally essential for non-ferrous metals, such as aluminum, copper, and titanium. Non-ferrous …

Read More »MIG vs TIG: Which One to Choose?

MIG vs TIG: Which One to Choose? Introduction Welding stands as one of the fundamental processes that underpin the modern world’s infrastructure and manufacturing landscape. From towering skyscrapers to intricate machinery, the art of joining metals has enabled the creation of structures and products that shape our daily lives. At …

Read More »Proper Alignment and Joint Fit-up

Proper Alignment and Joint Fit-up Proper alignment and joint fit-up play a pivotal role in ensuring the structural integrity and overall performance of various components, from construction projects to industrial machinery. Achieving a seamless connection between parts not only enhances the mechanical strength but also reduces the risk of failure, …

Read More »Thermo-mechanically Affected Zone in Friction Stir Welding

Thermo-mechanically Affected Zone in Friction Stir Welding Introduction Friction Stir Welding (FSW) is a revolutionary solid-state joining process that has gained immense popularity in various industries due to its advantages over conventional welding methods. However, during the FSW process, a unique zone called the Thermo-mechanically Affected Zone (TMAZ) is formed. …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders