Neutron Radiography Testing: Unveiling the Invisible Neutron radiography testing, a powerful and non-destructive imaging technique, has become indispensable in various industries. From ensuring the structural integrity of aerospace components to revolutionizing medical diagnostics, neutron radiography has carved a niche for itself in the realm of scientific innovation. How Neutron Radiography …

Read More »Knife-Line Attack in Stainless Steel

Knife-Line Attack in Stainless Steel Knife-Line Attack is a form of corrosion that can weaken Stainless Steel structures and components. It is characterized by the development of thin cracks along the grain boundaries of the material. These cracks can significantly reduce the strength of the steel and, if not controlled, …

Read More »The Most Dreaded Defects in Welding

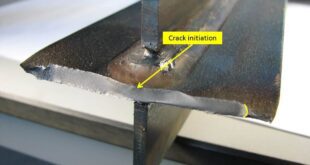

The Most Dreaded Defects in Welding In the world of metalworking and fabrication, welding is an indispensable process. Whether it’s building skyscrapers, constructing bridges, or crafting intricate art pieces, welding plays a vital role in joining metals. However, like any other process, welding is not without its challenges. Welders and …

Read More »Post Weld Heat Treatment Process (PHWT)

Post Weld Heat Treatment Process (PHWT) In the field of welding, achieving strong and reliable joints is crucial for ensuring the structural integrity and performance of various components. One effective method employed to enhance the properties of weldments is the Post Weld Heat Treatment Process (PHWT). This process involves subjecting …

Read More »Visual Inspection for Welding – Ensuring Quality and Integrity

Visual Inspection for Welding Welding plays a pivotal role in industries ranging from construction to manufacturing, creating strong and durable joints that are crucial for the integrity of structures and products. Ensuring the quality of these welds is paramount, and one of the most fundamental methods to achieve this is …

Read More »How To Improve Fatigue Life of Welded Joints?

How To Improve Fatigue Life of Welded Joints? Introduction In the realm of structural integrity and longevity, the significance of optimizing fatigue life in welded structures cannot be overstated. Welded joints serve as critical components in a myriad of applications, ranging from towering skyscrapers to intricate aerospace assemblies. The ability …

Read More »What is a Fillet Weld?

What is a Fillet Weld? Introduction Definition of Fillet Weld A fillet weld is a type of weld commonly used in joining two pieces of metal, typically at right angles, in a lap joint or a T-joint configuration. It is a weld that is triangular in cross-section and has a …

Read More »What Is Heat Affected Zone (HAZ)?

What Is Heat Affected Zone (HAZ)? Introduction Definition of the Heat Affected Zone (HAZ) The Heat Affected Zone (HAZ) refers to the region of a material that undergoes significant changes in its microstructure and mechanical properties due to the heat generated during welding or heat treatment processes. When heat is …

Read More »Mold Tool and Die Repair Welding

Mold Tool and Die Repair Welding Introduction Overview of mold tool and die repair welding Mold tool and die repair welding is a specialized process used to restore and repair damaged molds and dies used in various industries, such as manufacturing, automotive, and aerospace. Welding techniques are employed to fix …

Read More »Ultrasonic Testing – NDT Inspection

Ultrasonic Testing – NDT Inspection Introduction Ultrasonic Testing (UT) is a non-destructive testing (NDT) technique widely used in the field of welding inspection. It involves the use of high-frequency sound waves to detect and evaluate defects in welds without causing any damage to the tested material. In the world of …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders