Radiography Testing (RT)- NDT Inspection Introduction Radiography Testing (RT) is a non-destructive testing (NDT) method used in welding to inspect and evaluate the quality of welds. It involves the use of X-rays or gamma rays to create images of the internal structure of the welded components. The purpose of this …

Read More »Introduction to Destructive Weld Testing

Introduction to Destructive Weld Testing: Ensuring Strong and Reliable Joints Introduction Welding is a vital process in various industries, from construction and manufacturing to automotive and aerospace. The quality and reliability of welded joints play a crucial role in ensuring the structural integrity and safety of the finished product. To …

Read More »Penetrant Testing (PT) – NDT Inspection

Penetrant Testing (PT) – NDT Inspection Introduction Welcome to this comprehensive guide on Penetrant Testing (PT) – NDT Inspection. In this article, we will explore the various aspects of PT, its applications, techniques, inspection methods, advantages, limitations, and more. Whether you are new to the field or seeking to expand …

Read More »Welding in the Oil and Gas Industry

Welding in the Oil and Gas Industry Introduction Welding plays a crucial role in the oil and gas industry due to its importance in the production and transportation of energy resources. The sector heavily relies on welding to ensure the integrity and reliability of various structures and equipment. Without welding, …

Read More »Welding of Reactive and Refractory Metals

Welding of Reactive and Refractory Metals Introduction Definition and Significance of Welding Reactive and Refractory Metals Welding reactive and refractory metals is a crucial process in various industries, especially those that deal with extreme conditions and require materials with exceptional properties. Reactive metals, such as titanium, zirconium, and tantalum, are …

Read More »What is x-ray welding?

What is x-ray welding? Introduction Definition of X-ray welding X-ray welding is a specialized welding technique that utilizes X-rays to weld two pieces of metal together. The process involves using an X-ray machine to generate high-energy radiation, which is then directed onto the weld area to produce a weld. This …

Read More »Acoustic Emission Testing – NDT Inspection

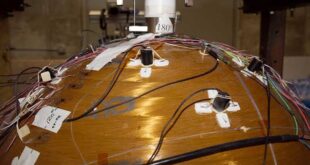

Acoustic Emission Testing – NDT Inspection Introduction Non-Destructive Testing (NDT) refers to a group of methods used to evaluate the properties and integrity of materials, structures, and components without causing damage to them. The primary objective of NDT is to detect defects, discontinuities, and other anomalies that may compromise the …

Read More »Eddy Current Testing (ECT) – NDT Inspection

Eddy Current Testing (ECT) – NDT Inspection Introduction Definition of Eddy Current Testing Eddy Current Testing (ECT) is a non-destructive testing (NDT) technique that is used to detect surface and near-surface defects in conductive materials. ECT works on the principle of electromagnetic induction and is capable of detecting defects such …

Read More »Magnetic Particle Inspection – NDT Inspection

Magnetic Particle Inspection – NDT Inspection Introduction Magnetic Particle Inspection (MPI) is a non-destructive testing (NDT) technique used to detect surface and subsurface defects in ferromagnetic materials. This method utilizes the magnetic properties of materials to identify defects that are not visible to the naked eye. MPI is commonly used …

Read More »Radiographic Testing – NDT Inspection

Radiographic Testing – NDT Inspection Introduction Radiographic testing (RT) is a non-destructive testing (NDT) technique that uses electromagnetic radiation, typically X-rays or gamma rays, to produce an image of the internal structure of an object. Radiographic testing is commonly used in a variety of industries, including welding technology, to ensure …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders