Rusty Metal Welding: Techniques, Tips, and Challenges You Need to Know Introduction Rusty metal, with its reddish-brown patina, is a common sight, particularly in outdoor environments where exposure to moisture and oxygen accelerates the corrosion process. As metal structures age, they often succumb to rust, leading to weakened integrity and …

Read More »Welding Copper and Copper Alloys

Welding Techniques for Copper and Copper Alloys Introduction Copper and its alloys are welded using various methods tailored to specific needs. Tungsten Inert Gas (TIG) welding ensures precision, making it ideal for thin copper sections, while Gas Metal Arc Welding (GMAW) or MIG welding is preferred for thicker components due …

Read More »Welding Thin Pipes and Tubes

Welding Thin Pipes and Tubes: A Comprehensive Guide Introduction Welding thin pipes and tubes requires a unique set of skills and techniques to ensure a strong and reliable bond. Whether you’re a seasoned welder or just starting in the world of welding, this guide will provide you with valuable insights …

Read More »Hot Wedge Welding

Hot Wedge Welding: Applications, Functionality, Materials, and Safety Introduction: Hot Wedge Welding (HW) is a versatile and efficient welding technique widely employed in various industries. This ultimate guide aims to provide comprehensive insights into the uses, functionality, materials, and safety considerations associated with Hot Wedge Welding. Overview of Hot Wedge …

Read More »Crane Rail Welding Process

Crane Rail Welding Process Introduction Definition and Purpose of Crane Rail Welding Crane rail welding is the process of permanently joining two sections of crane rail tracks through various welding techniques. The primary purpose of crane rail welding is to create a continuous, smooth, and strong rail track to support …

Read More »Ultrasonic Testing – NDT Inspection

Ultrasonic Testing – NDT Inspection Introduction Ultrasonic Testing (UT) is a non-destructive testing (NDT) technique widely used in the field of welding inspection. It involves the use of high-frequency sound waves to detect and evaluate defects in welds without causing any damage to the tested material. In the world of …

Read More »How to Weld Plastic?

How to Weld Plastic? Introduction Plastic welding plays a crucial role in various industries and applications. The ability to join plastic parts together effectively opens up a world of possibilities in fields such as manufacturing, automotive, construction, and even DIY projects. By understanding and mastering plastic welding techniques, individuals can …

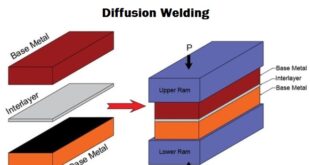

Read More »What is Diffusion Welding?

What is Diffusion Welding? Introduction Diffusion welding is a joining process that involves the bonding of two or more materials through the diffusion of atoms across the joint interface. It is a solid-state welding technique that does not require the melting of the base materials. Instead, it relies on high …

Read More »Friction Stir Welding and Process

Friction Stir Welding and Process Introduction Friction Stir Welding (FSW) is a solid-state welding process that was developed in the 1990s. It involves the joining of metals without melting the material, and instead uses friction and pressure to create a strong bond between the two pieces. FSW has become an …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders