Common Welding Failures Introduction Welding is a fundamental process in manufacturing and construction, crucial for joining metals and creating structures of all kinds. However, despite its widespread use and importance, welding is not immune to failures. These failures, also known as welding defects, can compromise the integrity, strength, and safety …

Read More »Welding Defect Repair Guide

Art of Welding Defect Repair: A Comprehensive Guide Introduction Welding is both an art and a science, where skilled craftsmen fuse metal components to create structures of strength and integrity. However, in the intricate dance of heat and metal, imperfections can arise, jeopardizing the integrity of the weld. Understanding how …

Read More »Welding Thin Pipes and Tubes

Welding Thin Pipes and Tubes: A Comprehensive Guide Introduction Welding thin pipes and tubes requires a unique set of skills and techniques to ensure a strong and reliable bond. Whether you’re a seasoned welder or just starting in the world of welding, this guide will provide you with valuable insights …

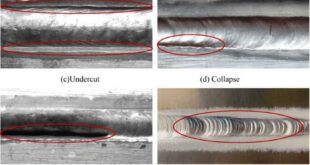

Read More »Undercut in Welding

Unveiling the Undercut in Welding Welding, a crucial industrial process, is not without its challenges. One such challenge that often goes unnoticed but can significantly compromise weld integrity is “undercut.” In this article, we’ll dive deep into the world of undercut in welding, exploring its causes, identification methods, impact on …

Read More »The Most Dreaded Defects in Welding

The Most Dreaded Defects in Welding In the world of metalworking and fabrication, welding is an indispensable process. Whether it’s building skyscrapers, constructing bridges, or crafting intricate art pieces, welding plays a vital role in joining metals. However, like any other process, welding is not without its challenges. Welders and …

Read More »Welding Techniques for Lead

Welding Techniques for Lead: A Comprehensive Guide Lead is a heavy and soft metal that finds its use in various industries, including battery manufacturing, radiation shielding, and plumbing. Lead welding is a crucial skill in various industries, from construction to plumbing. Whether you’re a seasoned welder or just starting, understanding …

Read More »Essential Welding Equipment And Tools

Essential Welding Equipment And Tools Introduction Welding is a fundamental process used in the manufacturing, construction, and repair of metal structures and equipment. It involves heating two metal parts to their melting points and joining them together by melting a filler metal into the joint. Welding is a highly specialized …

Read More »What is Welding Timer?

What is Welding Timer? Introduction Welding is a fundamental process used across various industries, from manufacturing to construction, to join metals and materials. Ensuring high-quality welds while maximizing productivity is crucial in these fields. One indispensable tool that contributes significantly to achieving this balance is the welding timer. In this …

Read More »What is a Fillet Weld?

What is a Fillet Weld? Introduction Definition of Fillet Weld A fillet weld is a type of weld commonly used in joining two pieces of metal, typically at right angles, in a lap joint or a T-joint configuration. It is a weld that is triangular in cross-section and has a …

Read More »Welding Techniques for Cast Iron

Welding Techniques for Cast Iron Introduction Welding is a fundamental process in the world of manufacturing and construction, enabling the joining of diverse materials to create robust and intricate structures. Among the various materials that welders encounter, cast iron holds a unique position due to its distinct properties and challenges …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders