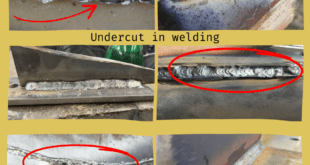

Understanding Acceptable Welding Undercut and Its Acceptance Criteria Welding undercut is a groove melted into the base metal adjacent to the weld toe that isn’t filled with weld metal. While some degree of undercut may seem minor, excessive or poorly formed undercut can reduce fatigue life, create stress risers, and …

Read More »Welding Inspectors

The Role and Duties of a Welding Inspector In the welding industry, structural integrity and safety hinge on more than just skilled welders and advanced equipment — they depend significantly on the vigilance and expertise of welding inspectors. These professionals are the backbone of welding quality assurance, tasked with ensuring …

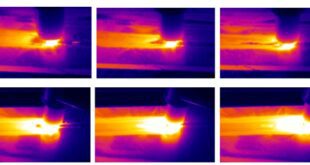

Read More »Infrared Thermography Testing

Infrared Thermography Testing – NDT Inspection Infrared Thermography Testing (IRT) is a powerful method in the realm of Non-Destructive Testing (NDT) used to evaluate materials, components, or systems without causing any damage. It’s like having X-ray vision for heat, enabling professionals to detect flaws, inconsistencies, or defects in welded joints …

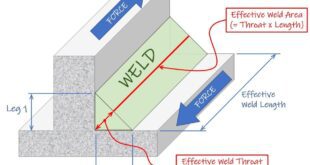

Read More »Fillet Weld Size

How to measure Fillet Weld Size Welding is an essential process in many industries, and fillet welds are one of the most common types of welds used to join metal parts. However, the quality of a fillet weld largely depends on its size, which directly affects its strength and functionality. …

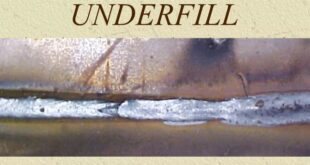

Read More »What is Underfill in Welding

What is Underfill in Welding Introduction to Underfill in Welding In welding, achieving a strong and defect-free weld is essential for ensuring the structural integrity of a joint. However, welding defects can occur if the process isn’t carefully controlled. One such defect is underfill, which can lead to serious issues …

Read More »Mastering Flange Welding: A Comprehensive Guide for Welders

Mastering Flange Welding Flange welding is a critical process in various industries, especially in sectors like construction, manufacturing, and petrochemicals. It involves joining two pipes or connecting a pipe to a pressure vessel, pump, or valve by welding a flange to each end of the pipe. This creates a secure …

Read More »Welding Defect Repair Guide

Art of Welding Defect Repair: A Comprehensive Guide Introduction Welding is both an art and a science, where skilled craftsmen fuse metal components to create structures of strength and integrity. However, in the intricate dance of heat and metal, imperfections can arise, jeopardizing the integrity of the weld. Understanding how …

Read More »Planar Defects in Welding

Planar Defects in Welding: Ensuring Strong, Flawless Joints Welding is a critical process in the fabrication of various structures, and while it provides strength and durability, it’s not immune to imperfections. Planar defects in welding can compromise the integrity of joints, leading to structural issues and reduced service life. In …

Read More »Ultrasonic Testing – NDT Inspection

Ultrasonic Testing – NDT Inspection Introduction Ultrasonic Testing (UT) is a non-destructive testing (NDT) technique widely used in the field of welding inspection. It involves the use of high-frequency sound waves to detect and evaluate defects in welds without causing any damage to the tested material. In the world of …

Read More »How to Weld Varying Diameter Pipes

How to Weld Varying Diameter Pipes Introduction Welding varying diameter pipes can be a challenging task that requires expertise and precision. Whether you’re working on a plumbing project, industrial construction, or any other application involving pipes, understanding the proper techniques for welding different pipe diameters / pipe welding is essential. …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders