What is Whipping Welding? Introduction Definition of Whipping Welding Whipping welding is a specialized welding technique that involves the use of a circular or zigzag motion to create weld beads. This technique is characterized by the rhythmic back-and-forth movement of the welding torch or electrode. The motion creates overlapping weld …

Read More »Acoustic Emission Testing – NDT Inspection

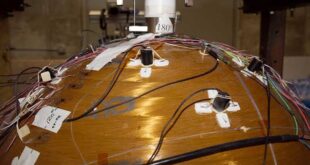

Acoustic Emission Testing – NDT Inspection Introduction Non-Destructive Testing (NDT) refers to a group of methods used to evaluate the properties and integrity of materials, structures, and components without causing damage to them. The primary objective of NDT is to detect defects, discontinuities, and other anomalies that may compromise the …

Read More »Self-Shielded Flux Cored Welding

Self-Shielded Flux Cored Welding Introduction Self-Shielded Flux Cored Welding is a welding process that uses a continuous, tubular electrode filled with flux to join two pieces of metal together. Unlike traditional welding methods, this process does not require an external shielding gas to protect the weld pool from atmospheric contamination. …

Read More »Radiographic Testing – NDT Inspection

Radiographic Testing – NDT Inspection Introduction Radiographic testing (RT) is a non-destructive testing (NDT) technique that uses electromagnetic radiation, typically X-rays or gamma rays, to produce an image of the internal structure of an object. Radiographic testing is commonly used in a variety of industries, including welding technology, to ensure …

Read More »Boilermaker Certification and Training

Boilermaker Certification and Training Introduction Explanation of boilermaking Boilermaking is a specialized field within the construction and manufacturing industries that involves the fabrication, installation, and maintenance of boilers, tanks, and pressure vessels. Boilermakers work with a variety of materials, including steel, aluminum, copper, and brass, and use specialized tools and …

Read More »What Is Explosion Welding?

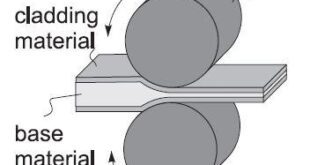

Introduction Explosion welding, also known as explosive welding or EXW, is a solid-state welding process that uses the energy generated by a chemical explosion to bond two or more dissimilar metals or alloys. The process is characterized by the formation of a high-velocity jet of metal that collides with a …

Read More »What is Cold Welding?

What is Cold Welding Introduction Definition of cold welding: Cold welding is a solid-state welding process in which two metals are joined together at room temperature under high pressure, without the need for heat or external energy. Brief history and discovery of cold welding Cold welding was first discovered in …

Read More »Welding Electrodes and Filler Materials

Welding Electrodes and Filler Materials Introduction Welding is a widely used process in the manufacturing industry to join two or more metal parts together. It involves melting the base metal and adding a filler material to create a strong joint. One of the critical factors in welding is the choice …

Read More »Do’s and Don’ts in Welding

Do’s and Don’ts in Welding Introduction Welding is a vital process used in many industries, including construction, manufacturing, and automotive repair. It involves the use of heat and pressure to fuse two or more metal parts together, creating a strong, permanent bond. However, welding can also be a hazardous activity …

Read More »Effects of Welding Variables on Welding Quality

Effects of Welding Variables on Welding Quality Introduction Welding is a process of joining two or more materials, usually metals or thermoplastics, by heating them to their melting point and then cooling them to form a permanent bond. The welding process can be performed using various methods such as gas …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders