Preventing Flashback and Backfire in Gas Welding

Gas welding is a powerful and versatile technique widely used in metal fabrication. However, like any process involving flammable gases and high temperatures, it comes with serious risks. Among the most dangerous are flashbacks and backfires, two events that can lead to equipment damage, injury, or even explosions if not properly understood and managed.

Understanding Flashback and Backfire

Before we can prevent flashbacks and backfires, we need to understand what they are and how they differ.

What Is a Backfire?

A backfire is a sharp popping sound that occurs when the flame momentarily extinguishes and then relights, often caused by touching the flame to the molten pool or by dirty or overheated torch tips.

Common causes of backfire include:

Partially blocked torch tips

Operating too close to the work surface

Excessively low gas pressure

Overheating the tip

What Is a Flashback?

A flashback is much more severe. It occurs when the flame travels back into the torch, hose, or regulator. It may be accompanied by a hissing or whistling noise and, in the worst-case scenario, can ignite the gas inside the hoses or cylinders.

Dangers of flashbacks:

Hose rupture or bursting

Torch or regulator explosions

Fire hazards in the surrounding environment

Root Causes of Flashback and Backfire

Both incidents typically stem from a combination of equipment faults, user errors, or incorrect gas setups.

Equipment-Related Causes

Worn Torch Tips: Over time, torch tips wear out, develop carbon buildup, or get partially blocked. These conditions can cause irregular gas flow leading to backfire.

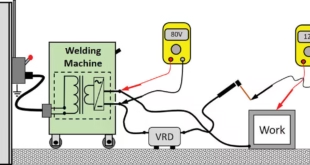

Faulty Regulators or Valves: If the pressure regulators aren’t delivering stable output, a pressure drop can allow a reverse flow of gas.

Cracked Hoses: Leaky hoses can draw in air, altering the gas mixture and allowing the flame to burn back.

Operational Errors

Lighting the Torch Incorrectly: Igniting the torch with the valves fully open or in the wrong sequence can cause unstable flames.

Shutting Off Abruptly: Quickly turning off the oxygen or acetylene can suck the flame back into the torch body.

Improper Tip Use: Using tips not designed for the torch or project type creates turbulence and improper combustion.

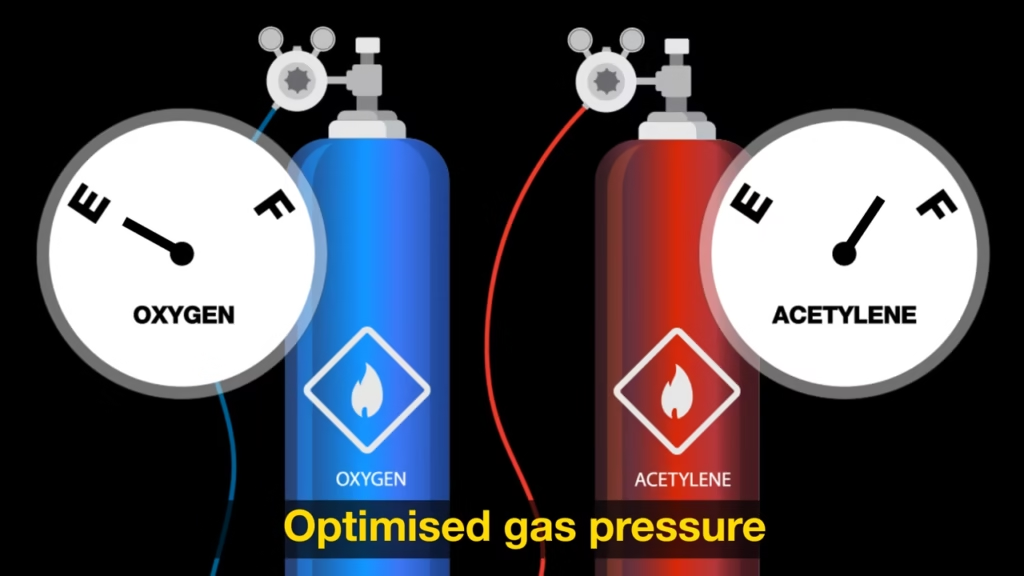

Gas Flow and Mixture Issues

Incorrect Oxygen-to-Acetylene Ratio: A neutral flame requires the proper balance. If one gas overwhelms the other, combustion may become unstable.

- Blockages: Dust, metal particles, or carbon can obstruct flow, causing pressure to build and backflash.

Equipment Design Features That Prevent Flashbacks

Thankfully, many modern tools include safety mechanisms to limit the risk of flashbacks.

Flashback Arrestors

These small but critical components stop a flashback from traveling beyond the torch.

Location: Usually installed at the torch inlet or regulator outlet.

How They Work: A combination of flame barrier and pressure-sensitive valve that seals the gas line in the event of a reverse flame.

Types: Some are built-in to torches; others are external and screw onto fittings.

Non-Return Valves (Check Valves)

Check valves allow gas to flow in one direction only, preventing reverse flow that could lead to flashbacks.

Often used in conjunction with flashback arrestors.

Protect both the user and the gas supply system.

Torch Design and Tip Selection

Torches with heat-dissipating heads and correctly sized tips help reduce the chance of overheating and turbulent flow.

Tips designed for specific gas pressures promote a stable flame.

Best Practices for Safe Operation

Much of flashback and backfire prevention comes down to how you operate and maintain your equipment.

Proper Setup Procedures

Leak Testing: Always use a soapy solution or leak detection fluid to inspect all joints and connections before lighting the torch.

Correct Regulator Settings: Follow manufacturer guidelines for oxygen and fuel pressures. Overpressurization can encourage backfires.

Correct Lighting and Shutdown Techniques

Lighting: Open the fuel valve slightly, ignite, then slowly introduce oxygen to achieve a neutral flame.

Shutdown: Turn off the acetylene first, then the oxygen. Releasing oxygen first can create a vacuum effect that draws the flame back.

Monitoring Flame Behavior

Watch for:

Fluctuating flame length

Hissing or popping noises

Unusual flame colors

Maintenance and Inspection Protocols

Routine inspections are critical to catching faults before they become hazards.

Routine Equipment Checks

Daily: Visually inspect torch tips, hose fittings, and valve operation.

Weekly: Perform leak tests and inspect hose flexibility.

Monthly: Test flashback arrestors and check check-valve performance.

Replacing Damaged Components

Torch Tips: Replace when carbonized or deformed.

Hoses: Change out any that are cracked, stiff, or leaking.

Flashback Arrestors: Replace according to manufacturer recommendations or after a flashback event.

Training and Awareness

Even with perfect equipment, untrained operators pose a serious risk.

Educating Welders on Flashback Risks

Include real-life demonstrations in training programs.

Stress the difference between backfires and flashbacks and how to respond.

Encourage understanding over memorization.

Importance of Emergency Procedures

If Flashback Occurs: Shut off gas supply immediately and evacuate if needed.

Know Your Gear: All welders should know where their shutoff valves and fire extinguishers are located.

Regulatory and Safety Standards

Following national safety codes helps standardize and enforce best practices.

OSHA and ANSI Recommendations

OSHA 1910.253 mandates use of flashback arrestors and check valves in many gas welding applications.

ANSI Z49.1 provides safety rules specific to oxy-fuel welding and cutting.

Industry Best Practices

AWS Recommendations: The American Welding Society encourages dual check systems and routine audits.

Manufacturer Guidelines: Always read and follow equipment manuals. Different brands have specific pressure ranges and procedures.

FAQs

What is the difference between a flashback and a backfire?

A backfire is a loud pop caused by the flame briefly extinguishing and reigniting at the tip. A flashback is more dangerous and occurs when the flame travels backward into the hose or regulator.

How do flashback arrestors work?

They contain a flame barrier and check valve that stops the flame and gas from traveling in reverse, preventing it from reaching upstream equipment or gas cylinders.

Can I reuse flashback arrestors after a flashback incident?

It’s generally not recommended. After a flashback, inspect or replace the arrestor as its internal components may be damaged.

What gas mixture increases the risk of flashbacks?

An improper ratio of oxygen to acetylene, especially when oxygen is set too high, can destabilize the flame and increase flashback risk.

Are flashback arrestors required by law?

Yes, in many jurisdictions. OSHA regulations and ANSI standards both recommend or require the use of arrestors and check valves on oxy-fuel system.

Conclusion

Preventing flashback and backfire in gas welding is not just about equipment — it’s about mindset, training, and vigilance. By understanding the root causes and recognizing early warning signs, welders can protect themselves, their coworkers, and their work environment from unnecessary danger.

With proper tools like flashback arrestors, consistent maintenance, and good habits, we can weld safely, confidently, and effectively every time the torch is lit.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders