Welding Cracks and How to Prevent Them

Welding is a critical process in various industries, ranging from construction to manufacturing. However, despite its importance, welding can lead to structural weaknesses if not performed correctly. One of the most common issues encountered in welding is the occurrence of cracks. These cracks can compromise the integrity of the weld and ultimately jeopardize the safety of the entire structure. In this article, we will explore the causes of welding cracks and provide valuable insights into preventing them.

Understanding the Causes of Welding Cracks

To effectively prevent welding cracks, one must first comprehend the underlying factors that contribute to their formation. These causes can vary depending on the welding process, material properties, and environmental conditions. Broadly categorized, the primary causes of welding cracks include thermal stresses, residual stresses, and metallurgical factors.

Thermal Stresses

During welding, the localized heating and subsequent rapid cooling of the base metal and weld metal induce thermal stresses within the welded joint. Variations in thermal expansion and contraction rates between the base metal and filler metal create internal forces that can exceed the material’s yield strength, leading to crack initiation and propagation.

Residual Stresses

Residual stresses, arising from the uneven distribution of temperature and deformation during welding, persist in the welded structure even after the cessation of welding. These residual stresses can exceed the material’s strength, particularly in regions with geometric constraints or abrupt changes in cross-section, predisposing the welded joint to cracking under applied loads or thermal cycles.

Metallurgical Factors

The metallurgical composition and microstructure of the base metal, filler metal, and heat-affected zone (HAZ) influence the susceptibility to welding cracks. Factors such as alloy content, grain size, and impurities can promote crack formation through mechanisms such as liquation, solidification cracking, or hydrogen-induced cracking.

Hydrogen Embrittlement

Hydrogen, present in the welding environment or absorbed by the metal during the process, can lead to hydrogen embrittlement. This phenomenon occurs when hydrogen atoms accumulate at grain boundaries, weakening the material and making it susceptible to cracking.

Contamination

Contaminants such as oil, grease, or moisture on the surface of the metal can interfere with the welding process and create defects in the weld, including cracks. Proper cleaning and preparation of the welding surfaces are essential for preventing contamination-related issues.

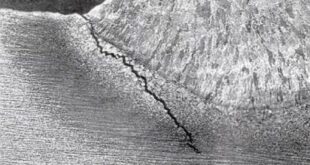

Types of Welding Cracks

Welding cracks, though they share a common consequence of compromised integrity, can manifest in distinct forms and under varying conditions. Understanding the specific characteristics and behaviors of different types of welding cracks is essential for devising targeted prevention and mitigation strategies. Here, we delve into three prevalent categories: hot cracks, cold cracks, and stress cracks.

Hot Cracks

Hot cracks, also known as solidification cracks or liquation cracks, occur during the solidification phase of the weld metal. As the molten weld pool cools and solidifies, localized regions may experience constrained contraction due to surrounding solid metal. This constraint restricts the movement of the solidifying metal, leading to the development of tensile stresses within the weld bead. If the material’s ductility is insufficient to accommodate these stresses, micro-cracks may initiate and propagate within the solidifying weld metal. Hot cracks typically form perpendicular to the direction of solidification and are commonly observed in materials prone to liquation or segregation of alloying elements.

Cold Cracks

In contrast to hot cracks, cold cracks, also referred to as hydrogen-induced cracking or delayed cracking, occur after the completion of welding, often during the cooling phase or even hours or days later. Cold cracks are predominantly associated with the presence of hydrogen in the weld metal or base material. Hydrogen, introduced from sources such as moisture, contaminants, or electrode coatings, diffuses into the weld metal during welding and becomes trapped within its microstructure. Subsequent exposure to tensile stresses, either from residual stresses or external loading, prompts the hydrogen to recombine into molecular hydrogen, exerting internal pressure within the material. If the material’s ductility is compromised or if critical stress thresholds are exceeded, cold cracks may propagate along grain boundaries or other susceptible regions within the weldment.

Stress Cracks

Stress cracks, also known as mechanical or fatigue cracks, arise from the cumulative effect of cyclic loading or mechanical stresses acting on the welded structure over time. Unlike hot or cold cracks, which primarily result from thermal or hydrogen-related mechanisms, stress cracks originate from the application of mechanical forces that exceed the material’s fatigue strength or endurance limit. These cracks may initiate at stress concentration points, such as weld toe geometries or sharp changes in cross-section, where the local stress levels are elevated. Over successive loading cycles, micro-cracks propagate, eventually leading to visible cracking and potential structural failure.

Techniques for Preventing Welding Cracks

Preventing welding cracks requires a comprehensive approach that addresses various aspects of the welding process, material selection, and operational parameters. By implementing effective techniques and best practices, welders can minimize the risk of crack formation and ensure the integrity of welded joints. Here, we explore six key strategies for crack prevention:

Proper Joint Preparation

The foundation of a successful weld begins with meticulous joint preparation. Properly cleaning and profiling the joint surfaces, removing any contaminants, oxides, or surface irregularities, ensures optimal fusion between the base metals and promotes uniform distribution of weld metal. Additionally, employing appropriate joint geometries and ensuring proper fit-up minimizes residual stresses and reduces the likelihood of crack initiation at the weld interface.

Control of Heat Input

Controlling the heat input during welding is crucial for managing thermal stresses and minimizing the risk of cracking. By adjusting parameters such as welding current, voltage, travel speed, and heat input per unit length, welders can tailor the energy input to match the specific requirements of the base materials and welding process. Avoiding excessive heat input reduces the likelihood of overheating, distortion, and metallurgical changes that can predispose the welded joint to cracking.

Selection of Suitable Welding Processes

Different welding processes exhibit varying characteristics in terms of heat input, arc stability, and metallurgical effects. Choosing the most appropriate welding process for the specific application and material properties can significantly influence crack susceptibility. Processes such as gas metal arc welding (GMAW), shielded metal arc welding (SMAW), or flux-cored arc welding (FCAW) offer distinct advantages in terms of control over heat input, filler metal composition, and shielding gas effectiveness, contributing to crack prevention.

Proper Electrode Selection

The selection of electrode or filler material plays a critical role in weld quality and crack prevention. Matching the composition and mechanical properties of the electrode to those of the base metal helps ensure compatibility and reduces the risk of metallurgical incompatibilities that can lead to cracking. Additionally, low-hydrogen electrodes or filler metals with controlled levels of hydrogen content are preferred for applications where hydrogen-induced cracking is a concern.

Preheating and Post-Weld Heat Treatment

Preheating the base metal prior to welding and applying post-weld heat treatment (PWHT) procedures can effectively mitigate residual stresses and reduce the risk of cracking. Preheating slows down the cooling rate during welding, allowing for more uniform thermal gradients and minimizing the potential for stress concentration. PWHT relieves residual stresses and promotes microstructural homogenization, enhancing the weld’s mechanical properties and resistance to cracking.

Managing Welding Parameters

Maintaining strict control over welding parameters, including arc length, travel speed, electrode angle, and interpass temperature, is essential for achieving consistent and defect-free welds. Monitoring and adjusting these parameters throughout the welding process help optimize heat distribution, control weld bead geometry, and minimize the accumulation of residual stresses. Additionally, implementing robust welding procedures and qualification protocols ensures repeatability and reliability in crack prevention efforts.

Advanced Strategies for Crack Prevention

While basic techniques lay the groundwork for crack prevention in welding, advanced strategies offer additional layers of refinement and optimization. By incorporating these advanced approaches into welding practices, welders can further enhance weld quality and resilience against cracking. Here, we explore three advanced strategies for crack prevention:

Welding Sequence Optimization

Optimizing the welding sequence can exert significant influence on residual stress distribution and crack susceptibility. By strategically planning the sequence in which weld passes are made, welders can minimize the accumulation of residual stresses and thermal gradients within the welded structure. Sequential welding, starting from the center and progressing outward, or employing alternating welding directions, helps distribute thermal effects more uniformly, reducing the likelihood of stress concentration and crack initiation. Additionally, staggering weld passes and allowing sufficient cooling time between passes can mitigate the buildup of residual stresses and enhance weld integrity.

Use of Filler Metals and Fluxes

The careful selection of filler metals and fluxes can contribute to crack prevention by optimizing weld chemistry and shielding characteristics. Filler metals with tailored compositions, including low-hydrogen variants and alloys designed for specific applications, help mitigate hydrogen-induced cracking and enhance weld mechanical properties. Fluxes, when utilized in processes such as submerged arc welding (SAW) or flux-cored arc welding (FCAW), provide a protective atmosphere that reduces the risk of atmospheric contamination and assists in slag removal, promoting clean welds with reduced susceptibility to cracking.

Stress Relieving

Stress relieving, also known as post-weld heat treatment (PWHT), is a controlled thermal process applied after welding to alleviate residual stresses and enhance the mechanical properties of the welded structure. By subjecting the welded component to elevated temperatures within a predefined range, typically below the material’s transformation temperature but above its recrystallization temperature, stress-relieving treatments facilitate the relaxation of residual stresses and promote microstructural stabilization. This thermal conditioning not only reduces the risk of cracking but also improves weld ductility, toughness, and resistance to fatigue, ensuring the long-term reliability of the welded assembly.

Importance of Quality Control and Inspection

In addition to preventive measures, rigorous quality control and inspection are essential for detecting and addressing potential defects in welds. Visual inspection, non-destructive testing techniques such as ultrasonic or X-ray testing, and adherence to industry standards and specifications play a crucial role in ensuring weld integrity.

Case Studies and Real-World Applications

Examining case studies and real-world examples provides valuable insights into the practical implications of welding crack prevention techniques and the consequences of crack failures. Here, we explore two contrasting scenarios:

Examples of Welding Crack Failures

Welding crack failures can have significant repercussions, ranging from structural integrity issues to safety hazards and costly downtime. One notable example occurred in a pressure vessel used in a petrochemical plant. Despite adherence to welding procedures and quality control measures, a hidden crack formed during fabrication due to inadequate preheat and hydrogen contamination. Over time, the crack propagated under cyclic loading, leading to catastrophic failure and a release of hazardous materials. The incident resulted in environmental damage, regulatory scrutiny, and substantial financial losses for the plant operator. This case underscores the critical importance of diligent crack prevention measures and comprehensive inspection protocols in high-consequence applications.

Successful Implementation of Crack Prevention Techniques

In contrast, a case study involving the construction of a bridge structure showcases the successful implementation of crack prevention techniques. Welding engineers employed a combination of preheating, controlled heat input, and stress-relieving treatments to mitigate the risk of cracking in critical weld joints. Additionally, meticulous selection of filler metals with low hydrogen content and adherence to stringent welding procedures ensured weld quality and integrity. Subsequent non-destructive testing confirmed the absence of defects, validating the effectiveness of the crack prevention measures. The completed bridge structure surpassed performance expectations, withstanding environmental stresses and providing reliable service over its operational lifespan. This case highlights the importance of proactive crack prevention strategies and demonstrates their tangible benefits in enhancing weld quality and structural durability.

FAQs

How common are welding cracks, and are they preventable?

Welding cracks are relatively common but can be prevented through proper welding techniques and adherence to preventive measures.

What role does material selection play in preventing welding cracks?

Choosing materials with lower susceptibility to cracking, along with controlling hydrogen levels and employing suitable welding procedures, can significantly reduce the risk of welding cracks.

Why is preheating important in welding crack prevention?

Preheating helps reduce thermal gradients and residual stresses in the base metal, minimizing the likelihood of crack formation during welding.

What are some signs of potential welding cracks during visual inspection?

Visual inspection may reveal discontinuities, irregularities, or fissures along the weld bead or adjacent areas, indicating the presence of potential cracks.

How can welders ensure the effectiveness of post-weld heat treatment?

Proper execution of post-weld heat treatment, including adherence to specified temperature and duration parameters, is essential for achieving the desired stress relief and metallurgical transformation in the weldment.

Conclusion

In conclusion, welding cracks pose significant challenges in various industries, but with proper understanding of the causes and preventive measures, they can be effectively mitigated. By implementing techniques such as preheating, post-weld heat treatment, and rigorous quality control, welders can ensure the integrity and reliability of their welds, ultimately contributing to safer and more durable structures.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders