Welding Defects and their Types

Introduction

Welding defects are unacceptable imperfections that occur during the welding process. Weld quality depends on the mechanical properties of the materials, it can be quantitative or qualitative. Mostly “fit-for-service” approach is used i.e., the fabricated weld can perform the intended service. But in some projects, the weld flaws may cause critical problems, these flaws then become defects and may adversely affect the mechanical properties required for the given application. Weld defects can produce catastrophic results if they are not identified and not properly addressed.

Welding Defects

Welding defects are unacceptable imperfections that occur during the welding process. Any imperfection or unwanted technical or design deviation is termed as a defect in the welding process i.e., deviation from ideal code and standards. There are many parameters that become reasons for these defects. These parameters can be any of these imperfect weldings, choosing the wrong electrode, poor conditions for welding, lack of skill and practice, or incorrect measurements of parameters. They may occur at any step during the welding process. These can be easily detected in the form of geometric imperfections. These defects can affect both the metallic structure of the material internally and externally. According to welding societies, there are codes and standards for acceptable limits of imperfections or discontinuities e.g., EN ISO 6520-1. when imperfections or discontinuities exceed the given limits then in welding terms it becomes a weld defect. It is important for weld quality to identify the defect correctly so that proper actions are taken to prevent further occurrence.

Types of Welding Defects

There are two types of welding defects based on their location. These types are:

- External Welding Defects

- Internal Welding Defects.

External welding defects are those that appear on the surface of the weld and can be visualized with the naked eye. Examples of external defects are porosity, undercut, overlaps, craters, surface cracks, underfill, spattering, excessive penetration, and arc strikes.

Internal welding defects are those which are not on the surface of the material and can not be seen through the naked eye. Examples of internal defects are incomplete fusion, incomplete penetration, slag inclusion, internal porosity, and internal cracks.

Both internal and external types of welding defects are common welding processes. here is a detailed explanation of these defects and their causes, remedies, and prevention to avoid these defects.

Types of Welding Defects

Here are some common weld discontinuities that occur during any welding process:

Porosity

Porosity occurs as rounded pores, it happens because of excessive moisture. these also present as cavities formed due to the solidification/freezing of gases in the weld pool. These discontinuities occur as many forms like surface-breaking pores.

Remedies

- To avoid porosity, choose suitable/right electrode and filler materials.

- To avoid porosity, use a larger welding arc

- Apply more gas flow and ensure gas has proper pressure and flow

Incomplete fusion

it happens when weld metal does not fuse to the base metal properly. it is because of applying incorrect welding method. it is because of lack of proper fusion of weld metal and base metal. sometimes, it also appears in adjoining weld beads. This creates a gap in the joint that is not filled with molten metal.

Causes

- Insufficient heat input

- wrong type or size of the electrode or electrode angle

- improper or faulty joint design

- inadequate gas shielding.

- production of slag on weld groove

- low welding current

- too much welding speed

- Linear misalignment

Remedies

- Follow the correct welding guidelines with proper specification

- electrode position must correct

- Cleaning the weld surface before the welding

Weld spattering

Weld spattering is formed by droplets of molten material that are scattered during the welding process and resulting in the formation of unsightly bubbles of material. Weld spatter/molten droplets can potentially be causing safety issues like burn injuries as these droplets travel through the air.

Causes

- High arc current and damp electrodes cause spattering

- Wrong selection of electrodes

- Contamination with other materials

- improper wire feeding speed

Remedies

- lowering the current and arc length

- Use dry electrodes i.e., the right selection of electrodes

Undercut

Undercut is a defect in the form of a groove at the weld toe produced by the base material that melted and was drawn into the weld metal. typical causes of undercuts are improper welding techniques, improper weld parameters, high welding currents or voltages, improper weaving width, and higher welding speed.

Overlap

Overlap occurs at the toe of the weld, i.e., the region of lack of fusion. Overlap is the projection of weld metal beyond the weld toe or weld root. It occurs because of poor control of the welding process, improper selection of the welding materials, or improper preparation of materials prior to welding.

Prevention

- A proper welding technique

- Use of smaller electrodes

- the right amount of current and voltage

- Change to flat position

Laminations

Laminations are a type of internal welding defect, they can be tested through a non-destructive method i.e., by use of ultrasonic testing. these are caused by gas voids, gapping and water drops, and shrinkage of cavities.

Seams and laps

Seams and laps are longitudinal base metal discontinuities that occur in forged and rolled products, or both. They can cause cracking and should be avoided.

Incomplete penetration

It refers to an incomplete penetrated weld through the joint. This is actually not necessarily a discontinuity since many joints often do not require full penetration. It is a joint root condition in a groove weld in which weld metal does not extend through the joint thickness/length. It is the failure of filler metal or base metal to completely fill the root of the weld.

Causes

- Insufficient root opening

- Insufficient heat input

- Misalignment of weld

- wrong type or size of the electrode or electrode angle

- improper or faulty joint design

Remedies

- Use proper joint geometry and joint design

- Follow welding procedure specification

- Adjust electrode or workpiece position

- Use smaller electrodes to increase root opening

- Improve visibility

Excessive penetration / Burn through

causes of excessive penetration are large joint gaps, small root faces, or higher heat inputs. it can cause erosion/corrosion. For reduction of these defects use better pipe fittings and ensure correct weld technique

Prevention

- Reduce arc voltage/current or both

- Increase the welding speed

- Use proper electrode

Root concavity

Root concavity occurs because of shrinkage of the weld pool. Melting of the root pass by the second pass can also produce root concavity.

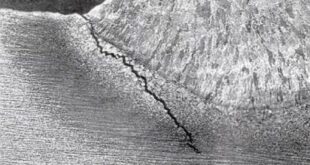

Cracks

Cracks are local discontinuities, formed in the weld and base metal when localized stresses exceed the ultimate strength of the material. They may occur at elevated temperatures during weld metal solidification. High residual stresses and hydrogen embrittlement are causes of crack formation. Welding cracks are brittle in nature, exhibiting little plastic deformation at the crack boundaries.

Types of cracks

Solidification cracks occur during the weld solidification process

Hydrogen-induced cracks diffuse out into parent metal on cooling

Mechanical damage

Mechanical damage is surface material damage occurred during the manufacturing process. The mechanical properties of materials used in welding cause various types of weld discontinuities The mechanical properties include tensile strength, ductility, impact, and fracture toughness, and fatigue strength. Any of these properties may be degraded by a welding discontinuity.

Excessive Weld Reinforcement

Excessive weld reinforcement refers to an overbuildup of weld material beyond the required specifications. In simpler terms, it’s when more weld material is deposited than necessary for the intended application. This can lead to several issues, including compromised structural integrity and aesthetic concerns.

FAQs

What is the most serious welding defect?

The most serious welding defect is likely to be a complete lack of fusion, as it can cause the welded joint to fail under load.

How are welding defects classified?

Welding defects can be classified in a variety of ways, including by the type of defect (e.g. incomplete fusion, porosity, cracking), the cause of the defect (e.g. poor technique, incorrect equipment or parameters), and the location of the defect (e.g. in the weld metal, heat-affected zone, or base metal).

What is the best way to avoid developing weld defects?

The best way to avoid developing weld defects is to follow proper welding procedures, use appropriate equipment and welding materials, and ensure that the welder is properly trained and experienced. Also, performing quality control checks on the finished welds.

What is the importance of welding defects?

Welding defects can have a significant impact on the strength and integrity of the welded joint, and can lead to premature failure of the structure or component.

What kind of defects should not be in good welding?

Some of the defects that should not be present in good welding include incomplete fusion, porosity, cracking, and excessive undercut.

What causes cracks in welding?

Cracks in welding can be caused by a variety of factors, including improper welding technique, incorrect welding parameters, improper preheat or post-weld heat treatment, and the presence of contaminants in the weld area.

What is the most common welding process?

The most common welding process is likely to be shielded metal arc welding (SMAW or stick welding), which is widely used in a variety of industries and applications.

Why weld usually fails in HAZ?

Welds can fail in the heat-affected zone (HAZ) due to a variety of reasons, including thermal stress, metallurgical changes, and improper preheat or post-weld heat treatment.

What is the type of welding defect caused due to poor?

A type of welding defect caused due to poor technique is called “undercut” which occurs when the weld metal is not properly fused to the base metal, leaving a groove or undercut along the edge of the weld. This can weaken the weld and increase the risk of failure.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders