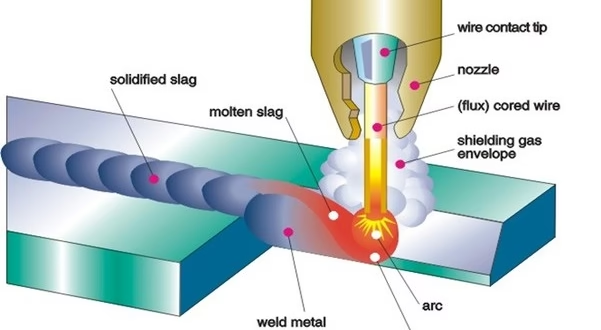

Flux-Cored Arc Welding: Self-Shielded vs Gas-Shielded Welding is at the core of modern metal fabrication, making it possible to construct bridges, ships, skyscrapers, and pipelines. Among the numerous welding methods available today, Flux-Cored Arc Welding (FCAW) has carved a niche for itself, especially in heavy industrial sectors. This semi-automatic or …

Read More »

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders