Plasma Transferred Arc Welding: The Complete Guide

Introduction

Plasma Transferred Arc Welding (PTA) might sound like something straight out of a science fiction movie, but it’s actually a cutting-edge welding technique used across various industries. From aerospace to oil and gas, PTA welding offers unparalleled precision and versatility. But what exactly is PTA welding, and why is it so important? Let’s dive in and find out.

Understanding Plasma Transferred Arc Welding

How Does PTA Welding Work?

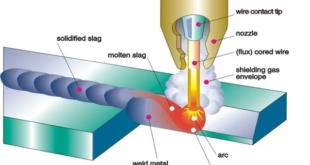

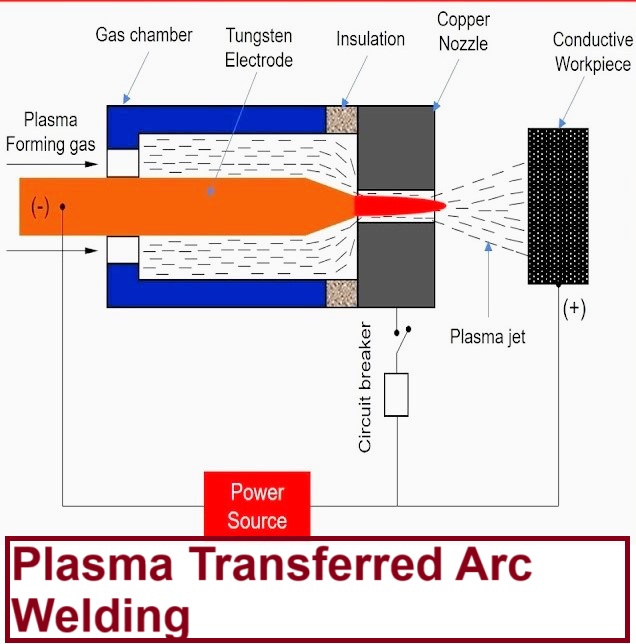

At its core, PTA welding uses a plasma arc to transfer melted material from a welding electrode to the workpiece. The plasma arc, generated by ionizing a gas (usually argon), creates intense heat that melts the material and deposits it onto the surface, forming a strong, metallurgically bonded coating. This process is incredibly precise, allowing for detailed and high-quality welds.

Key Components of PTA Welding System

To understand how PTA welding works, let’s break down its key components:

- Plasma Torch: The heart of the system, where the plasma arc is generated. The torch directs the plasma arc towards the workpiece and ensures that the arc is stable and focused.

- Power Supply: Provides the necessary electrical energy to create the plasma arc. The power supply must be reliable and capable of delivering a consistent output to maintain the quality of the weld.

- Control System: Manages the parameters like current, voltage, and gas flow. The control system allows the operator to fine-tune the welding process, ensuring optimal conditions for each specific application.

- Powder Feeder: Delivers the welding material in powder form to the plasma arc. The feeder must be precise to ensure that the right amount of material is deposited uniformly.

Advantages & Disadvantages

Advantages of Plasma Transferred Arc Welding

Precision and Control

One of the standout features of PTA welding is its precision. The ability to control the plasma arc and the deposition of the material with high accuracy makes it ideal for applications requiring intricate details and minimal material waste. This precision ensures that the weld is not only strong but also aesthetically pleasing. For instance, in the aerospace industry, precise coatings on turbine blades can significantly enhance their performance and longevity.

Versatility

PTA welding is incredibly versatile. It can be used on a wide range of materials, including metals and alloys, and is suitable for various applications, from coating components to repairing worn-out parts. Whether you’re working with hard-to-weld materials or performing complex repairs, PTA welding can handle it. This versatility is especially valuable in the automotive industry, where different components require specific material properties to function optimally.

Cost Efficiency

While the initial setup cost for PTA welding might be high, the long-term benefits include reduced material wastage, higher quality welds, and less need for post-weld treatments. This makes it a cost-effective solution for many industries. Over time, the investment pays off as the efficiency and quality of the welds lead to lower operational costs. For example, in the oil and gas sector, the durability of PTA welded components can result in fewer replacements and reduced maintenance costs.

Disadvantages of Plasma Transferred Arc Welding

Initial Setup Cost

The sophisticated equipment required for PTA welding can be expensive. This includes the plasma torch, power supply, and control systems, making the initial investment quite high. Small businesses or workshops might find the cost prohibitive. However, for large-scale operations, the long-term savings and benefits can justify the initial expenditure.

Technical Expertise Required

Operating a PTA welding system requires specialized knowledge and skills. Training and experience are crucial to ensure high-quality welds and to maintain the equipment properly. Without the right expertise, the quality of the welds can suffer, and equipment can be damaged. Regular training and certification programs can help bridge this gap and ensure operators are well-versed in the latest techniques and safety protocols.

PTA Welding Process in Detail

Step-by-Step Procedure

- Preparation: Clean the workpiece to remove any contaminants. This step is crucial to ensure that the weld adheres properly and that no impurities compromise the integrity of the weld.

- Setup: Configure the welding parameters on the control system. This includes setting the current, voltage, and gas flow rate to match the specific requirements of the job.

- Welding: Initiate the plasma arc and start the welding process, feeding the powder material into the arc. The operator must carefully monitor the process to ensure that the material is deposited evenly.

- Cooling: Allow the welded area to cool down naturally or with the aid of cooling systems. Proper cooling is essential to prevent any thermal distortion or cracking.

- Inspection: Check the weld quality using appropriate inspection techniques. This might include visual inspection, radiographic testing, or ultrasonic testing to ensure that the weld meets the required standards.\

Safety Measures and Precautions

Safety in PTA welding is paramount. Proper protective gear, including gloves, goggles, and aprons, should be worn. Adequate ventilation is necessary to avoid inhalation of fumes. Regular maintenance of equipment helps prevent accidents and ensures smooth operation. Additionally, operators should be trained in emergency procedures to handle any unexpected situations. For instance, knowing how to safely shut down the system in case of a malfunction can prevent injuries and equipment damage.

Equipment and Materials Used in PTA Welding

Essential Tools and Machinery

- Plasma Torch: Generates the plasma arc. It’s designed to handle high temperatures and provide a stable arc.

- Power Supply: Provides electrical energy. A reliable power supply is crucial for consistent welding performance.

- Control System: Manages welding parameters. Advanced control systems can automate many aspects of the welding process, enhancing precision.

- Powder Feeder: Supplies welding material. The feeder must be accurate and consistent to ensure high-quality welds.

Suitable Materials and Alloys

PTA welding is compatible with various materials, including stainless steel, nickel-based alloys, cobalt-based alloys, and titanium. This flexibility makes it suitable for a wide range of industrial applications, from aerospace components to automotive parts. For example, nickel-based alloys are often used in the aerospace industry for their high-temperature resistance, while cobalt-based alloys are favored in the medical field for their biocompatibility.

Applications of PTA Welding

Aerospace Industry

In aerospace, PTA welding is used for coating turbine blades, landing gear, and other critical components. The precision and reliability of PTA welding ensure the safety and performance of these high-stress parts, which must withstand extreme conditions. The ability to apply wear-resistant coatings extends the lifespan of these components, reducing the need for frequent replacements.

Automotive Industry

PTA welding is employed in the automotive sector for coating engine parts, such as valves and pistons, enhancing their durability and performance. The ability to apply wear-resistant coatings makes it invaluable for extending the life of critical components. This results in better engine performance and reduced maintenance costs for vehicles.

Oil and Gas Sector

The oil and gas industry utilizes PTA welding for hard-facing and repairing drilling tools, pipelines, and valves, extending their service life and reducing downtime. These applications demand materials that can resist corrosion and wear, which PTA welding provides. For example, hard-facing with cobalt-based alloys can significantly enhance the durability of drilling tools used in harsh environments.

Repair and Maintenance

PTA welding is ideal for repairing worn-out components. The ability to deposit material accurately means that only the damaged area is repaired, preserving the integrity of the entire part. This is especially useful for expensive or difficult-to-replace components. For instance, repairing a turbine blade using PTA welding can save significant costs compared to replacing the entire blade.

Comparing with Other Welding Techniques

PTA vs. TIG Welding

While both PTA and TIG welding offer precision, PTA welding stands out due to its ability to deposit material with minimal dilution, making it ideal for coating applications. TIG welding, on the other hand, is typically used for joining metals with a high degree of control. For instance, TIG welding is preferred for creating clean, high-quality welds on thin materials, whereas PTA welding excels in adding durable coatings.

PTA vs. MIG Welding

MIG welding is typically faster but lacks the precision of PTA welding. PTA welding’s controlled environment results in higher quality and more durable welds, whereas MIG welding is often preferred for its speed and ease of use in less critical applications. MIG welding is commonly used in construction and manufacturing where speed and efficiency are prioritized over precision.

PTA vs. Laser Welding

Laser welding offers high precision like PTA welding but can be more expensive and less versatile in terms of the range of materials it can handle. Laser welding is ideal for applications requiring very fine, precise welds, while PTA welding is better suited for heavy-duty coating and repair tasks. For example, laser welding is often used in the electronics industry for creating micro-welds, whereas PTA welding is used in industrial applications requiring robust coatings.

Future Trends in PTA Welding

Technological Advancements

The future of PTA welding looks promising with ongoing advancements in automation, control systems, and plasma torch technology. These improvements will enhance precision, reduce costs, and broaden the application scope. Innovations such as real-time monitoring and adaptive control systems are expected to make PTA welding even more efficient and reliable. For instance, integrating AI and machine learning into control systems can optimize welding parameters in real-time, improving weld quality and reducing waste.

Emerging Applications

New applications in medical device manufacturing, renewable energy, and microelectronics are emerging as industries recognize the benefits of PTA welding’s precision and versatility. For example, the ability to create wear-resistant coatings on medical implants or components for renewable energy systems is driving new research and development. In the field of renewable energy, PTA welding can be used to enhance the durability of wind turbine components, leading to longer service life and reduced maintenance costs.

FAQs

What is the difference between PTA welding and plasma arc welding?

PTA welding uses a plasma arc to transfer material in powder form onto the workpiece, while plasma arc welding primarily focuses on joining metals using a plasma arc without the powder material deposition.

Can PTA welding be automated?

Yes, PTA welding can be automated, enhancing precision, efficiency, and repeatability, especially for large-scale industrial applications.

What are the common issues faced in PTA welding?

Common issues include porosity, cracking, and inconsistent material deposition, often caused by improper parameter settings or poor maintenance of equipment.

How do you maintain PTA welding equipment?

Regular maintenance involves cleaning the plasma torch, checking and replacing worn-out parts, and calibrating the control systems to ensure optimal performance.

Is PTA welding suitable for small-scale projects?

While PTA welding is typically used for industrial applications, it can be adapted for small-scale projects, especially those requiring high precision and quality.

Conclusion

Plasma Transferred Arc Welding is a powerful and versatile technique that plays a crucial role in various industries. Its precision, control, and ability to work with a wide range of materials make it an invaluable tool for both manufacturing and repair applications. As technology advances, PTA welding will continue to evolve, opening up new possibilities and applications.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders