Welding Galvanized Steel: Techniques, Safety, and Best Practices Introduction Welding Galvanized Steel, a process that joins two pieces of steel together, plays a crucial role in various industries, including construction, automotive, and manufacturing. Galvanized steel is coated with a layer of zinc to protect it from corrosion, making it an …

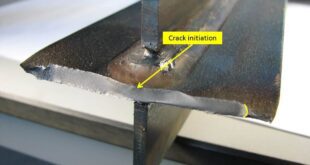

Read More »How To Improve Fatigue Life of Welded Joints?

How To Improve Fatigue Life of Welded Joints? Introduction In the realm of structural integrity and longevity, the significance of optimizing fatigue life in welded structures cannot be overstated. Welded joints serve as critical components in a myriad of applications, ranging from towering skyscrapers to intricate aerospace assemblies. The ability …

Read More »Crane Rail Welding Process

Crane Rail Welding Process Introduction Definition and Purpose of Crane Rail Welding Crane rail welding is the process of permanently joining two sections of crane rail tracks through various welding techniques. The primary purpose of crane rail welding is to create a continuous, smooth, and strong rail track to support …

Read More »Ultrasonic Testing – NDT Inspection

Ultrasonic Testing – NDT Inspection Introduction Ultrasonic Testing (UT) is a non-destructive testing (NDT) technique widely used in the field of welding inspection. It involves the use of high-frequency sound waves to detect and evaluate defects in welds without causing any damage to the tested material. In the world of …

Read More »Welding in the Oil and Gas Industry

Welding in the Oil and Gas Industry Introduction Welding plays a crucial role in the oil and gas industry due to its importance in the production and transportation of energy resources. The sector heavily relies on welding to ensure the integrity and reliability of various structures and equipment. Without welding, …

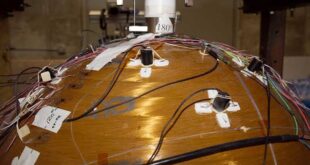

Read More »Acoustic Emission Testing – NDT Inspection

Acoustic Emission Testing – NDT Inspection Introduction Non-Destructive Testing (NDT) refers to a group of methods used to evaluate the properties and integrity of materials, structures, and components without causing damage to them. The primary objective of NDT is to detect defects, discontinuities, and other anomalies that may compromise the …

Read More »How To Become CSWIP 3.1 Welding Inspector?

How To Become CSWIP 3.1 Welding Inspector? Introduction CSWIP 3.1 certification is a globally recognized certification scheme for welding inspectors developed by the Certification Scheme for Welding Inspection Personnel (CSWIP), which is a division of TWI Ltd. This certification is considered to be a standard for welding inspection and is …

Read More »Eddy Current Testing (ECT) – NDT Inspection

Eddy Current Testing (ECT) – NDT Inspection Introduction Definition of Eddy Current Testing Eddy Current Testing (ECT) is a non-destructive testing (NDT) technique that is used to detect surface and near-surface defects in conductive materials. ECT works on the principle of electromagnetic induction and is capable of detecting defects such …

Read More »NDT Non-Destructive Testing

NDT Non-Destructive Testing Introduction Non-Destructive Testing (NDT) is a group of techniques used in science and industry to evaluate the properties of a material, component or system without causing any damage to it. This means that the inspection process does not alter or affect the material or component in any …

Read More »Weld Testing Methods

Weld Testing Methods Introduction Weld testing is a crucial step in the manufacturing process of many industrial products, ensuring the strength and reliability of the welded joints. The objective of weld testing is to detect any defects or inconsistencies that might affect the structural integrity of the final product. Weld …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders