What Causes Welding Spatter? Welding spatter is caused by unstable molten metal droplets being ejected from the arc or weld pool. The instability arises from a combination of incorrect process parameters, consumable or base-metal contamination, poor shielding or gas flow, equipment faults, and operator technique. Fundamental physics of arc metal …

Read More »MIG Welding Settings

MIG Settings by Thickness (MIG Settings Chart & Tuning Guide) Getting MIG (GMAW) settings right begins with metal thickness. Thickness determines the transfer mode you can use, the wire size you should load, the gas you should choose, and—ultimately—the voltage and wire feed speed (WFS) that give sound fusion without …

Read More »Acceptable Porosity

How Much Porosity Is Acceptable in a Weld? Porosity is like the tiny potholes of the welding world — small, hidden, and sometimes harmless, but in the wrong spot or quantity, they can cause catastrophic failure. So, how much porosity is too much? The answer isn’t a one-size-fits-all — it …

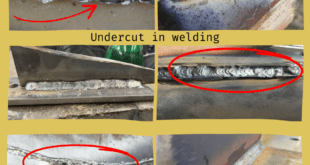

Read More »Acceptance Criteria for Undercut

Understanding Acceptable Welding Undercut and Its Acceptance Criteria Welding undercut is a groove melted into the base metal adjacent to the weld toe that isn’t filled with weld metal. While some degree of undercut may seem minor, excessive or poorly formed undercut can reduce fatigue life, create stress risers, and …

Read More »Blowholes

Understanding Blowholes in Welding: Causes, Prevention, and Inspection In the world of welding, we encounter various challenges. Welding isn’t just about melting metal; it’s about creating strong, reliable joints that meet specific standards. However, imperfections known as welding defects can arise, which may compromise the integrity, strength, and appearance of …

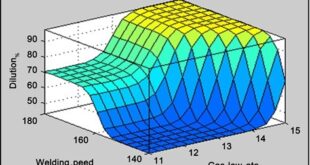

Read More »Weld Metal Dilution

Weld Metal Dilution Rate When you’re laying down a weld, there’s a quiet chemistry dance happening under the hood—the weld metal dilution rate. It might not sound too flashy at first, but trust me, understanding weld dilution can make or break your weld’s quality, strength, and life span. What is …

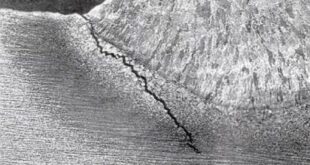

Read More »Chevron Cracking

What is Chevron Cracking in Welding? Welding is a fascinating process that binds metals together, but like any technical procedure, it’s not without its challenges. One such challenge is Chevron Cracking, a defect that can compromise the strength and integrity of welded joints. But what exactly is Chevron Cracking, and how …

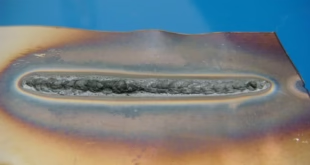

Read More »Sugaring In Stainless Steel

What Is Sugaring in Stainless Steel? What Does Sugaring Mean? Sugaring is a common term in welding that refers to the rough, oxidized surface that forms on stainless steel when it is exposed to oxygen during high-temperature processes, like welding. This grainy, sugar-like appearance usually forms on the underside of …

Read More »Infrared Thermography Testing

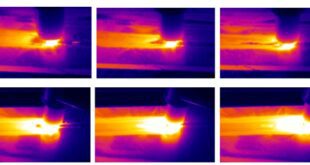

Infrared Thermography Testing – NDT Inspection Infrared Thermography Testing (IRT) is a powerful method in the realm of Non-Destructive Testing (NDT) used to evaluate materials, components, or systems without causing any damage. It’s like having X-ray vision for heat, enabling professionals to detect flaws, inconsistencies, or defects in welded joints …

Read More »Cold Cracking: Causes and Cures

Cold Cracking: Causes and Cures Introduction Welding is more than just joining metals—it’s about creating structures that can endure stress and last a long time. However, welding comes with challenges, and one of the most critical is cold cracking. Known as the “silent destroyer” of welds, cold cracking can occur …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders