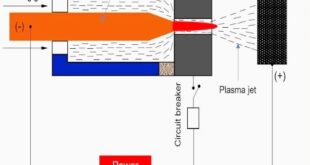

Plasma Transferred Arc Welding: The Complete Guide Introduction Plasma Transferred Arc Welding (PTA) might sound like something straight out of a science fiction movie, but it’s actually a cutting-edge welding technique used across various industries. From aerospace to oil and gas, PTA welding offers unparalleled precision and versatility. But what …

Read More »Preheating Metal Before Welding

Preheating Metal Before Welding Introduction Preheating involves heating the base metal to a specific temperature before welding. This preparatory step is often overlooked but is essential for certain materials and conditions. The brief overview of preheating in welding reveals its primary purpose: to reduce the risk of cracking, improve weld …

Read More »What Causes Pinholes in Welding?

What Causes Pinholes in Welding? Introduction In the intricate world of welding, pinholes are a persistent challenge that welders encounter. These tiny voids, often invisible to the naked eye, can significantly compromise the integrity and quality of a weld. Understanding what pinholes are and why they need to be addressed …

Read More »Pulse MIG Welding

Pulse MIG Welding Introduction Pulse MIG Welding, also known as Pulsed Gas Metal Arc Welding (GMAW-P), is an advanced welding process that involves the intermittent pulsing of current through the welding wire. Unlike conventional MIG (Metal Inert Gas) welding, where a constant voltage and current are applied, Pulse MIG Welding …

Read More »6g Welding Position

Mastering the 6G Welding Position: Challenges, Techniques, and Advantages Welding is a critical skill in various industries, from construction to manufacturing. The ability to weld proficiently in different positions is a hallmark of a skilled welder. Among the various welding positions, the 6G welding position stands out for its complexity …

Read More »Pulse TIG Welding

Pulse TIG welding Introduction Pulse TIG Welding represents a refinement of conventional TIG welding, wherein the welding current is modulated to alternate between high and low levels at a controlled frequency. Unlike continuous current welding, which applies a constant current throughout the welding process, pulse welding alternates between a peak …

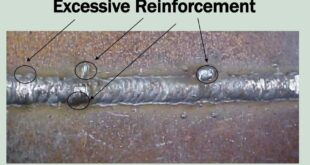

Read More »Excessive Weld Reinforcement

Excessive Weld Reinforcement Introduction Welding is a crucial process in various industries, from construction to manufacturing. It involves joining metals together using heat, pressure, or a combination of both. However, achieving the perfect weld isn’t always straightforward. One common issue that welders encounter is excessive weld reinforcement. Definition of Excessive …

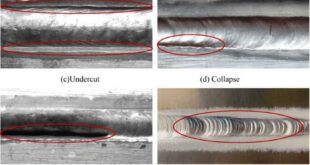

Read More »Welding Cracks and How to Prevent Them

Welding Cracks and How to Prevent Them Welding is a critical process in various industries, ranging from construction to manufacturing. However, despite its importance, welding can lead to structural weaknesses if not performed correctly. One of the most common issues encountered in welding is the occurrence of cracks. These cracks …

Read More »Can you Weld Rusty Metal?

Rusty Metal Welding: Techniques, Tips, and Challenges You Need to Know Introduction Rusty metal, with its reddish-brown patina, is a common sight, particularly in outdoor environments where exposure to moisture and oxygen accelerates the corrosion process. As metal structures age, they often succumb to rust, leading to weakened integrity and …

Read More »Multipass Welding

Multipass Welding Introduction to Multipass Welding Multipass welding is a sophisticated welding technique employed in various industries for joining materials of substantial thickness. Unlike single-pass welding, where the entire weld is completed in one pass, multipass welding involves layering multiple passes of weld metal to achieve the desired joint strength …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders