Understanding Weld Dilution and Chemical Inhomogeneity

Weld dilution refers to the mixing of the base metal and filler metal during the welding process. When two metals, typically the base metal and a consumable filler metal, come into contact and melt, they combine to form a new alloy at the weld interface. This fusion zone contains a mixture of the base metal and filler metal constituents. The degree of mixing or dilution can vary widely and depends on several factors, including welding process, parameters, base metal properties, and joint design.

Weld Dilution Fundamentals

Weld dilution lies at the heart of welding science, influencing the composition, structure, and properties of the final weld. In this section, we will delve into the fundamental aspects of weld dilution, breaking down its definition, the processes that govern it, and the different types that can occur.

Explanation of Weld Dilution and Chemical Inhomogeneity

Mixing of Base Metal and Filler Metal

At its core, weld dilution signifies the mingling of the base metal and the filler metal during the welding process. To appreciate this concept fully, it’s important to understand the sequence of events during welding. When a welder initiates an arc and applies heat to the base metal, it begins to melt. Simultaneously, the consumable filler metal, usually in the form of a wire or rod, is introduced into the weld pool.

As both the base metal and filler metal melt, they combine in the weld pool, leading to a mixing of their constituents. The extent of this mixing is influenced by several factors, including welding process, parameters (such as current, voltage, and travel speed), base metal properties (composition and thickness), and the design of the joint.

Implications of Chemical Inhomogeneity

- Corrosion Susceptibility: Welds with chemical inhomogeneity are more susceptible to corrosion, which can lead to premature failure in various applications.

- Inconsistent Mechanical Properties: The uneven distribution of alloying elements can result in inconsistent mechanical properties, making it challenging to predict the weld’s behavior under load.

- Difficulty in Non-Destructive Testing: Detecting defects and inconsistencies in chemically inhomogeneous welds through non-destructive testing methods can be challenging, posing potential safety risks.

Types of Weld Dilution

Weld dilution can manifest in two primary forms:

Fusion Zone Dilution

Fusion zone dilution refers to the mixing of the base metal and filler metal within the actual weld bead or fusion zone. In this region, the two materials combine to form an alloy with properties that are distinct from either the base metal or the filler metal. Controlling fusion zone dilution is crucial for achieving the desired mechanical properties and chemical composition of the weld.

Heat-Affected Zone (HAZ) Dilution

HAZ dilution occurs in the area surrounding the fusion zone, where the base metal’s properties are altered due to the influence of heat from the welding process. The heat-affected zone is especially important in welded structures, as changes in hardness, microstructure, and mechanical properties can affect the overall performance and integrity of the weld.

Factors Influencing Weld Dilution

The degree of weld dilution in a welding process is influenced by a multitude of factors, ranging from the choice of welding process and parameters to the properties of the base and filler metals, as well as the design and geometry of the joint. In this section, we will explore these factors in detail, highlighting their significance in determining the extent of weld dilution.

Welding Process

- Submerged Arc Welding (SAW): Submerged arc welding is characterized by the use of a granular flux that covers the welding arc and weld pool. This process is known for its high deposition rates and deep penetration. Due to the submerged nature of the arc, SAW typically results in lower dilution levels, as the flux acts as a barrier, preventing excessive mixing of base and filler metals.

- Gas Metal Arc Welding (GMAW): Gas metal arc welding, commonly known as MIG welding, employs a continuous solid wire electrode and a shielding gas. GMAW offers good control over dilution, with factors like electrode type and shielding gas composition playing a crucial role in determining the extent of dilution.

- Shielded Metal Arc Welding (SMAW): Shielded metal arc welding, or stick welding, utilizes a coated electrode that provides its own shielding. SMAW can exhibit moderate to high dilution levels depending on the electrode’s composition and the welding parameters used.

Welding Parameters

- Current: The welding current, measured in amperes, determines the heat input into the weld. Higher currents lead to increased melting of both base and filler metals, potentially resulting in higher dilution levels.

- Voltage: Voltage is another critical parameter affecting the welding process. Higher voltage settings can increase the arc length and heat input, influencing dilution levels.

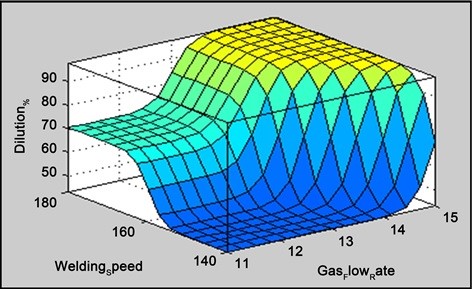

- Travel Speed: Travel speed, the rate at which the welding torch or electrode moves along the joint, plays a vital role in determining the degree of dilution. Faster travel speeds may reduce the time for mixing and result in lower dilution, while slower speeds can lead to higher dilution due to prolonged heat exposure.

Base Metal Properties

- Alloy Composition: The composition of the base metal significantly affects dilution. Alloys with different melting points and metallurgical properties will mix differently with the filler metal. Alloyed materials may require specific filler metals to achieve the desired dilution and properties.

- Thickness: Thicker base metals can act as heat sinks, absorbing more heat and potentially reducing dilution levels. Conversely, thinner materials are more susceptible to high dilution due to rapid heating and melting.

Filler Metal Characteristics

- Composition: The composition of the filler metal is a critical factor in determining dilution. Different filler metals are chosen based on their compatibility with the base metal and the desired alloying effects. Filler metal composition can be adjusted to achieve specific dilution goals.

- Size: The diameter or size of the filler metal electrode or wire influences the heat input and deposition rate. Smaller-diameter filler materials may result in lower dilution due to their lower heat input, while larger diameters can lead to higher dilution.

Joint Design and Geometry

- Joint Type (e.g., Butt Joint, Lap Joint): The type of joint being welded affects dilution. Butt joints, where two pieces are joined edge to edge, can experience higher dilution compared to lap joints, where one piece overlaps the other. Joint geometry impacts the accessibility of the weld pool to the base and filler metals.

- Bevel Angle: The angle and preparation of joint edges, known as the bevel angle, can influence dilution. Beveled edges allow better access for the filler metal to penetrate and mix with the base metal, potentially increasing dilution.

Measurement & Assessment of Weld Dilution

Accurately measuring and assessing weld dilution is essential for ensuring the quality and integrity of welded components. In this section, we will explore various methods and techniques for quantifying weld dilution, both non-destructive and destructive, and emphasize their importance in welding quality control.

Non-destructive Testing Methods

- Radiographic Testing: Radiographic testing, often referred to as X-ray or radiography, is a widely used non-destructive method for assessing weld quality, including dilution. It involves exposing the weld to X-rays or gamma rays, which pass through the material and create an image on a radiographic film or digital sensor. Variations in density caused by differences in composition (e.g., dilution) are visible in the resulting image, allowing inspectors to identify areas of concern.

- Ultrasonic Testing: Ultrasonic testing relies on the transmission of high-frequency sound waves through the weld. Any changes in material properties, such as dilution-induced variations in hardness or density, can cause reflections or echoes in the ultrasonic waves. These reflections are analyzed to determine the extent of dilution and potential defects within the weld.

Destructive Testing Methods

- Microstructure Analysis: Microstructure analysis involves taking cross-sectional samples of the weld and examining them under a microscope. This method allows for a detailed assessment of the weld’s microstructural characteristics, including grain size, phase distribution, and the presence of any intermetallic compounds. Dilution levels can be estimated by observing the distinct boundaries between base metal and filler metal regions within the microstructure.

- Chemical Analysis: Chemical analysis involves taking samples of the weld material and performing laboratory tests to determine its chemical composition. Dilution levels can be quantified by comparing the composition of the weld material to that of the base and filler metals. Techniques such as optical emission spectroscopy (OES) and energy-dispersive X-ray spectroscopy (EDS) are commonly used for this purpose.

Standards and Acceptance Criteria

To maintain consistency and ensure quality in welding processes, industry-specific standards and acceptance criteria are established. These standards provide guidelines for acceptable levels of weld dilution and other weld quality parameters. Commonly referenced standards include those developed by organizations like the American Welding Society (AWS) and the American Society for Testing and Materials (ASTM). Welding inspectors and engineers refer to these standards to determine whether a weld meets the specified requirements and whether further action is needed to control or rectify dilution issues.

Effects of Weld Dilution

Understanding the effects of weld dilution is pivotal in evaluating the overall quality and performance of welded components. In this section, we will explore how weld dilution impacts various aspects, including mechanical properties, corrosion resistance, microstructure, and residual stresses.

Mechanical Properties

- Strength: Weld dilution can significantly influence the strength of a weld. The mixed composition of the fusion zone resulting from dilution can lead to variations in material properties, potentially causing a decrease in tensile strength. High levels of dilution may weaken the weld, making it susceptible to premature failure under load.

- Toughness: Weld dilution can also affect the toughness of a weld, which is its ability to withstand applied stress without fracturing. Variations in composition and microstructure due to dilution may result in reduced toughness, making the weld more susceptible to brittle fracture, especially in low-temperature environments.

Corrosion Resistance

Corrosion resistance is a critical property in many applications, particularly those exposed to harsh environments. Weld dilution can alter the chemical composition of the fusion zone, potentially reducing the corrosion resistance of the weld. This is particularly concerning for materials that rely on a specific alloy composition to maintain their protective oxide layers. In cases of high dilution, localized corrosion or accelerated corrosion rates may occur, leading to premature degradation of the weld.

Microstructure Changes

Weld dilution can cause significant changes in the microstructure of the weld and the heat-affected zone (HAZ). These changes include variations in grain size, the formation of new phases, and the redistribution of alloying elements. Such microstructural alterations can impact mechanical properties, such as hardness and ductility, as well as the overall performance of the welded joint.

Residual Stresses

Welding induces thermal gradients and non-uniform heating and cooling rates in the welded material. This results in the development of residual stresses within the weld and the surrounding HAZ. The extent and distribution of these residual stresses are influenced by weld dilution. High dilution levels can exacerbate the non-uniform cooling process, leading to the accumulation of significant residual stresses. These stresses may contribute to weld distortion, cracking, and reduced fatigue life, potentially compromising the structural integrity of the welded component.

Mitigation and Control of Weld Dilution

Effectively managing and controlling weld dilution is crucial to achieving high-quality welds that meet specific performance requirements. In this section, we will explore various strategies and techniques for mitigating and controlling weld dilution, encompassing process optimization, material selection, joint design, and quality control measures.

Process Optimization

- Adjusting Welding Parameters: One of the primary ways to control weld dilution is by optimizing welding parameters such as current, voltage, and travel speed. Adjusting these parameters can help achieve the desired heat input, penetration depth, and mixing of base and filler metals. Fine-tuning parameters based on the specific welding application and material thickness can minimize excessive dilution.

- Selecting Appropriate Welding Process: Choosing the right welding process for the job can also impact dilution. For example, in applications where low dilution is critical, submerged arc welding (SAW) may be preferred due to its ability to minimize atmospheric exposure and dilution. Conversely, gas metal arc welding (GMAW) or gas tungsten arc welding (GTAW) can be selected for more precise control when higher dilution is acceptable.

Material Selection

- Filler Metal Selection: Filler metal selection plays a vital role in controlling dilution. Choosing filler metals with compositions that are compatible with the base metal and desired weld properties is essential. Alloyed filler metals can be selected to compensate for dilution-induced changes in composition, ensuring that the final weld meets specified requirements.

- Base Metal Selection: The choice of base metal can also influence dilution. In some cases, selecting a base metal with a specific alloy composition or thickness can help mitigate dilution concerns. Thicker base metals, for instance, may reduce heat transfer and dilution effects.

Joint Design Modifications

- Bevel Angles and Joint Configurations: Altering the joint design and geometry can impact dilution. Bevel angles, groove dimensions, and joint configurations can be modified to control the accessibility of the weld pool to the base and filler metals. Beveled edges can improve penetration and reduce excessive mixing of materials.

- Use of Backing Bars or Shields: Employing backing bars or shields can isolate the weld pool and prevent excessive dilution. These devices are particularly useful in situations where access to the backside of the weld is limited, such as in single-sided welding.

Preheat and Post-Weld Heat Treatment

- Preheat: Preheating the base metal before welding can help reduce the cooling rate and, subsequently, dilution effects. Preheat temperatures are typically determined based on material thickness and composition, and they can be an effective means of controlling dilution in thick sections.

- Post-Weld Heat Treatment: Depending on the material and application, post-weld heat treatment (PWHT) can be employed to relieve residual stresses and further refine the microstructure. PWHT can be used strategically to mitigate any adverse effects of dilution.

FAQs

How can I prevent excessive weld dilution?

Controlling welding parameters and choosing the right welding process are effective ways to prevent excessive dilution.

What is the role of alloying elements in welding?

Alloying elements are added to the filler material to improve the weld’s mechanical properties and corrosion resistance.

Can chemical inhomogeneity be completely eliminated?

While it can be minimized, complete elimination of chemical inhomogeneity is challenging due to the inherent complexities of welding.

Are there any non-destructive testing methods to detect chemical inhomogeneity?

Yes, techniques like ultrasonic testing and radiography can be used to identify chemical inhomogeneity without damaging the weld.

How does welding technique affect chemical inhomogeneity?

Different welding techniques and processes can lead to varying degrees of chemical inhomogeneity, so selecting the appropriate method is crucial.

What are some common applications of welding in industries?

Welding is used in a wide range of industries, including construction, automotive, aerospace, and shipbuilding.

Conclusion

Understanding weld dilution and chemical inhomogeneity is paramount for anyone involved in welding processes. These factors can significantly influence the quality and durability of welded joints. By carefully considering welding parameters, base metal composition, and post-weld treatments, welders can mitigate the negative effects of dilution and ensure the homogeneity of chemical elements in the final weld. Welding is both an art and a science, and mastering these aspects is essential for producing high-quality welds that stand the test of time.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders