What is Braze Welding?

Introduction

Definition

Braze welding, also known as brazing, is a joining process that involves the use of a filler metal to bond two or more base metals together. Unlike fusion welding techniques, which melt the base metals to form a joint, braze welding relies on the principle of capillary action to distribute the molten filler metal between the closely fitted surfaces of the joint. The filler metal used in braze welding has a lower melting point than the base metals, typically above 450°C (840°F) but below the melting point of the base metals.

Braze welding is commonly used in applications where the base metals have different melting points or when there is a need to minimize heat-affected zones and distortion. It is particularly suitable for joining dissimilar metals, such as copper to steel or stainless steel to aluminum. The process offers several advantages, including the ability to join materials with large differences in thickness, excellent joint strength, and enhanced resistance to corrosion.

Basic Principles of Braze Welding

Explanation of the Joining Process

Braze welding involves the creation of a joint between two or more base metals using a filler metal that has a lower melting point than the base metals. The joining process can be summarized in the following steps:

- Surface Preparation: The surfaces to be joined must be thoroughly cleaned and prepared to ensure proper adhesion. This typically involves removing oxides, grease, dirt, and other contaminants through methods such as degreasing, pickling, or mechanical cleaning.

- Flux Application: Flux is often used in braze welding to promote wetting and bonding between the base metals and the filler metal. The flux serves multiple functions, including removing surface oxides, preventing further oxidation during heating, and facilitating the flow of the molten filler metal into the joint.

- Heat Application: The base metals and the joint area are heated using a torch, furnace, or induction heating method. The heat source should provide uniform heating to bring the base metals and filler metal to their respective melting temperatures. The temperature is carefully controlled to avoid overheating or melting the base metals.

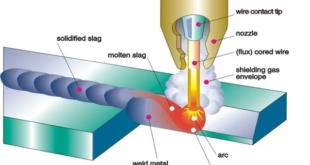

- Filler Metal Placement: Once the base metals reach the appropriate temperature, the filler metal, in the form of wire, foil, or pre-placed preforms, is introduced into the joint area. The heat from the base metals causes the filler metal to melt and flow into the joint by capillary action.

- Capillary Action and Solidification: The molten filler metal is drawn into the joint by capillary action due to the closely fitted surfaces and the flux’s surface tension-reducing properties. As the joint cools, the filler metal solidifies and forms a strong bond between the base metals.

- Post-Weld Cleaning and Inspection: After the joint has cooled, it is essential to remove any residual flux or other contaminants. This can be achieved through cleaning methods such as brushing, chemical cleaning, or mechanical means. Finally, the joint is inspected for quality, ensuring proper bonding, integrity, and conformity to desired specifications.

Materials and Equipment

Types of Base Metals Suitable for Braze Welding

Braze welding is suitable for joining a wide range of base metals, including:

- Metals: Ferrous Metals: Carbon steels, stainless steels, tool steels, cast iron.

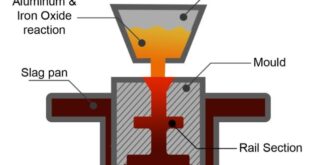

Non-Ferrous Metals: Copper, brass, bronze, aluminum, nickel, titanium, zinc, silver, gold. - Ceramics: Certain ceramics, such as alumina and zirconia, can be joined using specialized brazing techniques.

- Other Materials: Some plastics and composite materials with suitable properties can also be braze welded.

Filler Metals and Alloys Used in Braze Welding

The choice of filler metal depends on the specific base metals being joined and the desired properties of the joint. Common types of filler metals and alloys used in braze welding include:

- Silver-Based Alloys: Silver-based filler metals, often combined with copper, zinc, or other elements, offer excellent wetting properties and high strength joints. They are commonly used for joining copper, brass, and stainless steel.

- Copper-Based Alloys: Copper-based filler metals, such as bronze and brass alloys, are versatile and widely used for joining various materials, including ferrous and non-ferrous metals.

- Aluminum-Based Alloys: Aluminum-based filler metals are suitable for joining aluminum and its alloys. They offer good corrosion resistance and can be used for dissimilar metal joining.

- Nickel-Based Alloys: Nickel-based filler metals are commonly used for high-temperature applications, such as joining stainless steels and heat-resistant alloys.

- Flux-Core Filler Metals: Some filler metals come with a flux core, eliminating the need for separate flux application. These are convenient for certain applications, but the flux content should match the requirements of the joint and base metals.

Necessary Equipment and Tools for the Process

- Torches or Heating Devices: Various types of heating devices can be used in braze welding, depending on the scale and nature of the work. These include oxy-acetylene torches, oxy-propane torches, induction heaters, resistance heating devices, and furnace setups.

- Fluxes and Cleaning Agents: Fluxes are used to remove oxides and ensure proper wetting and bonding between the base metals and filler metal. Different fluxes are available for specific applications and base metal combinations. Cleaning agents, such as degreasers or pickling solutions, may also be required to prepare the base metal surfaces.

- Protective Gear and Safety Precautions: Braze welding involves high temperatures and potential hazards, so appropriate protective gear should be used. This includes safety glasses, gloves, aprons, and flame-resistant clothing. Adequate ventilation and respiratory protection may be necessary depending on the materials being used. Safety precautions such as fire extinguishers, fire blankets, and proper storage and handling of gases and chemicals should also be observed.

Additional tools and equipment that may be required include:

– Filler metal dispensers or feeders

– Flux applicators or brushes

– Wire cutters or shears for cutting filler metal

– Files, brushes, or abrasive materials for joint preparation and cleaning

– Clamps or fixturing devices to hold the workpieces in position during heating and cooling

Having the appropriate materials and equipment, as well as following safety guidelines, ensures the efficient and safe execution of the braze welding process.

Braze Welding Techniques

Torch Brazing

Description of the Process and Its Advantages:

Torch brazing is a braze welding technique that utilizes a torch or heating device to generate the necessary heat for joining. The process involves directing a focused flame onto the joint area to heat the base metals and melt the filler metal. The molten filler metal is then drawn into the joint by capillary action.

Advantages of Torch Brazing:

– Versatility: Torch brazing is suitable for both small-scale and large-scale applications.

– Mobility: Torch brazing allows for mobility and flexibility, as torches can be easily maneuvered to reach different areas and workpieces.

– Precise Heat Control: Torch brazing enables precise heat control, allowing for localized heating and minimizing heat-affected zones.

– Cost-Effectiveness: Torch brazing equipment is relatively affordable and requires less infrastructure compared to other brazing methods.

Types of Torches Used:

Different types of torches can be used for torch brazing, depending on the specific application and fuel source. Common torch types include:

– Oxy-Acetylene Torch: This torch uses a mixture of oxygen and acetylene gases to produce a hot flame suitable for various brazing applications.

– Oxy-Propane Torch: Similar to the oxy-acetylene torch, but it uses propane gas as the fuel source instead of acetylene.

– Air-Propane Torch: This torch uses propane gas and compressed air to create the flame for brazing.

Heat Control and Torch Manipulation:

In torch brazing, proper heat control and torch manipulation are crucial for achieving successful joints. Key considerations include:

– Distance: The torch should be positioned at an appropriate distance from the joint to achieve uniform heating without overheating.

– Angle: The torch flame should be directed at the joint at an optimal angle to ensure even heat distribution.

– Heat Application Sequence: Proper sequence and pattern of heat application are important, considering factors such as the thickness and heat conductivity of the materials being joined.

Furnace Brazing

Explanation of the Process and Its Benefits:

Furnace brazing is a braze welding technique that utilizes a furnace or controlled atmosphere chamber for heating the workpieces and melting the filler metal. The workpieces are placed inside the furnace, and the heat is evenly distributed to achieve brazing temperatures. Furnace brazing offers several benefits:

– Uniform Heating: Furnace brazing ensures consistent and uniform heating of the workpieces, resulting in reliable and high-quality joints.

– Batch Processing: Furnace brazing allows for batch processing of multiple workpieces simultaneously, increasing efficiency and productivity.

– Complex Part Joining: This technique is suitable for joining complex-shaped or large-sized components that may be challenging to braze using other methods.

Types of Furnaces Utilized:

Various types of furnaces can be used for furnace brazing, including:

– Continuous Belt Furnace: This type of furnace consists of a conveyor belt that moves the workpieces through a heating chamber, allowing for continuous processing.

– Batch-Type Furnace: Batch furnaces have a fixed chamber where the workpieces are loaded and heated together as a batch.

– Vacuum Furnace: Vacuum furnaces are used when brazing in a controlled or oxygen-free environment is required, such as for certain reactive or heat-sensitive materials.

Temperature Control and Cycle Times:

In furnace brazing, precise temperature control is essential to achieve the desired braze temperature and ensure proper filler metal flow and joint formation. The cycle times, including heating, holding, and cooling stages, are determined based on the specific materials, joint design, and filler metal being used. Monitoring and controlling the temperature and cycle times are critical for obtaining strong and defect-free joints.

Induction Brazing

Overview of the Method and Its Advantages:

Induction brazing is a braze welding technique that utilizes electromagnetic induction to heat the base metals and melt the filler metal. It involves placing the workpieces within an induction coil, which generates a high-frequency alternating magnetic field. This field induces electrical currents in the workpieces, resulting in localized heating and subsequent brazing.

Advantages of Induction Brazing:

– Rapid Heating: Induction brazing allows for rapid and localized heating, minimizing thermal distortion and reducing cycle times.

– Precise Heat Control: Induction brazing offers precise control over the heating process, allowing for targeted heat application.

– Automation Potential: Induction brazing can be easily integrated into automated production lines, improving efficiency and consistency.

Induction Heating Principles:

Induction heating relies on the principle of electromagnetic induction, where an alternating magnetic field induces electrical currents, known as eddy currents, in conductive materials. The eddy currents generate heat due to resistance, resulting in localized heating of the workpieces.

Equipment and Setup Requirements:

To perform induction brazing, the following equipment and setup are required:

– Induction Heating System: This includes an induction power supply, which generates the high-frequency alternating current, and an induction coil, which is designed to deliver the electromagnetic field to the joint area.

– Workpiece Fixturing: The workpieces need to be positioned within the induction coil, ensuring proper alignment and contact for efficient heating.

– Cooling System: An effective cooling system is necessary to dissipate heat from the workpieces after brazing.

The specific parameters, such as power settings, coil design, and heating duration, can be adjusted based on the materials, joint geometry, and desired brazing results.

Braze Welding Procedure

Flux Application and Its Role in the Process:

- Flux Selection: Selecting the appropriate flux is crucial for the success of the braze welding process. The flux serves multiple purposes, including:

- Removing oxides: Fluxes react with the oxides on the base metal surfaces, helping to clean and remove them. This improves the wetting and bonding characteristics of the filler metal.

- Promoting Wetting: Fluxes contain substances that enhance the wetting ability of the filler metal, allowing it to flow and spread evenly on the joint surfaces.

- Preventing Oxidation: Fluxes provide a protective barrier on the joint surfaces, preventing oxidation during the heating process.

- Flux Application: The flux is typically applied to the joint surfaces before heating. It can be in the form of a paste, powder, or liquid. The flux should be evenly distributed on the joint area, ensuring complete coverage of the mating surfaces. Excessive flux should be avoided as it can lead to flux entrapment or contamination of the joint.

Heating Techniques and Temperature Control:

- Heating Methods: Braze welding can be performed using various heating techniques, such as torch brazing, furnace brazing, or induction brazing, as discussed earlier. The heating method is selected based on the application, materials, and production requirements.

- Temperature Control: Precise temperature control is critical during the heating phase. The aim is to achieve the brazing temperature range, which is above the melting point of the filler metal but below the melting point of the base metals. Temperature control methods may include:

- Pyrometry: The use of temperature measurement devices, such as thermocouples or infrared pyrometers, to monitor and control the temperature during heating.

- Time-Temperature Profiles: Establishing specific heating profiles with defined ramp-up rates, dwell times, and cooling rates, which are optimized for the materials and joint configuration being brazed.

- Color Change Indication: Observing the color changes on the joint surfaces or flux to estimate the temperature range.

Filler Metal Application and Alloy Compatibility:

- Filler Metal Selection: Based on the joint requirements and materials being joined, the appropriate filler metal or alloy is selected. The filler metal should have a melting temperature below the brazing temperature and be compatible with the base metals.

- Filler Metal Placement: The filler metal is positioned or applied to the joint area. This can be done by placing preforms, wire, foil, or paste along the joint interface, depending on the specific application and filler metal form.

- Alloy Compatibility: It is essential to ensure compatibility between the filler metal and the base metals being joined. This includes considering factors such as melting temperature, thermal expansion coefficients, mechanical properties, and corrosion resistance to ensure a sound and reliable joint.

Post-Braze Treatment

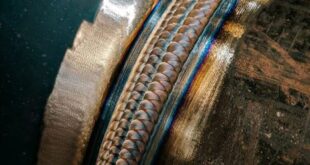

Cooling and Solidification of the Joint

After the brazing process is complete, the joint needs to be properly cooled and allowed to solidify. The cooling rate should be controlled to prevent thermal stresses or distortion in the joint. Depending on the size and complexity of the workpiece, cooling can be achieved through natural air cooling, quenching in water or oil, or controlled cooling in a furnace. It is important to follow the recommended cooling procedures specified for the specific brazing materials and joint configuration.

Cleaning and Removal of Flux Residues

Flux residues that remain on the joint surfaces after brazing must be thoroughly cleaned to ensure a clean and corrosion-resistant joint. Flux residues can be removed through the following methods:

- Mechanical Cleaning: Mechanical methods such as brushing, grinding, or blasting can be used to physically remove the flux residues. Care should be taken not to damage the joint or alter its dimensions during the cleaning process.

- Chemical Cleaning: Chemical cleaning agents or solutions can be applied to dissolve or remove the flux residues. The appropriate cleaning agent should be selected based on the type of flux used and the base metals involved. It is important to follow the manufacturer’s instructions and safety precautions when using chemical cleaning agents.

- Ultrasonic Cleaning: Ultrasonic cleaning involves immersing the brazed assembly in a cleaning solution and subjecting it to high-frequency sound waves. The vibrations produced by the sound waves help to dislodge and remove the flux residues from the joint surfaces.

FAQs

What is meant by braze welding?

Braze welding is a joining process that involves the use of a filler metal that melts above 450°C (840°F) but below the melting point of the base metals being joined. It forms a strong bond between the base metals without melting them.

What is the brazing process?

Brazing is a joining process that involves heating the base metals to a temperature above 450°C (840°F) and below their melting points. A filler metal with a lower melting point than the base metals is added, creating a strong bond between the metals when it solidifies.

Which gas is used for brazing?

Typically, an inert gas, such as nitrogen or argon, is used for brazing. These gases help create an oxygen-free environment to prevent oxidation during the brazing process.

What is the difference between brazing and braze welding?

The main difference between brazing and braze welding lies in the temperature and melting behavior of the filler metal. In brazing, the filler metal is added to the joint area as a separate material and melts to form the bond. In braze welding, the filler metal melts and fuses with the base metals, creating a stronger metallurgical bond.

What are four uses of brazing?

Brazing is commonly used in various industries and applications, including:

- Joining HVAC and refrigeration components.

- Manufacturing of heat exchangers and automotive radiators.

- Fabrication of plumbing and pipe fittings.

- Repairing and manufacturing jewelry.

What are three types of brazing?

The three common types of brazing are:

- Torch Brazing: Uses a flame torch to heat the joint area and melt the filler metal.

- Furnace Brazing: Involves placing the assembly in a controlled atmosphere furnace for heating and brazing.

- Induction Brazing: Utilizes induction heating to heat the joint area and melt the filler metal.

What material is used in brazing?

Various filler metals and alloys are used in brazing, depending on the specific application and materials being joined. Common filler metals include silver-based alloys, copper-based alloys, and nickel-based alloys.

What are three advantages of braze welding?

The advantages of braze welding include:

- Capability to join dissimilar metals.

- Compatibility with heat-sensitive materials.

- Excellent corrosion resistance.

- Cost-effectiveness compared to fusion welding processes.

What is the temperature of brazing?

Brazing typically occurs at temperatures above 450°C (840°F). The exact temperature depends on the melting points of the base metals being joined and the filler metal being used. The brazing temperature is lower than the melting point of the base metals to prevent them from melting during the process.

Conclusion

In conclusion, braze welding is a versatile and valuable joining technique that offers unique advantages and capabilities. It enables the joining of dissimilar metals, compatibility with heat-sensitive materials, and the creation of strong and durable joints. The technique provides excellent corrosion resistance and can be a cost-effective solution for various applications.

However, it is important to consider the limitations and specific considerations associated with braze welding. Temperature limitations, joint design and fit-up, material compatibility, joint appearance, pre-braze surface preparation, and joint strength in high-stress applications are factors that need to be carefully addressed.

By understanding the principles, materials, equipment, and techniques involved in braze welding, as well as considering the advantages and limitations, one can make informed decisions about its application in various industries and contexts. Proper joint preparation, precise temperature control, filler metal selection, and effective monitoring of the brazing process are crucial for achieving reliable and high-quality braze-welded joints.

Braze welding continues to play a significant role in manufacturing, repair, and fabrication industries, offering an alternative and complementary method to fusion welding. With careful attention to the specific requirements of each application, braze welding can provide strong, durable, and corrosion-resistant joints, contributing to the success and performance of diverse engineering projects.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders