What is Pattern Welding?

Introduction

Introduction to Pattern Welding

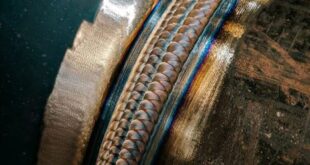

Pattern welding, also known as Damascus steel or Damascene technique, is a traditional method of forging metals to create intricate patterns and designs. It involves the joining and layering of different types of metals to produce a visually appealing and structurally strong composite material. Pattern welding has a rich history dating back centuries and has been practiced by various cultures around the world, including the Vikings, Celts, Persians, and Japanese.

Purpose and Significance

- Aesthetic Appeal: One of the primary purposes of pattern welding is to create visually stunning patterns and designs on the surface of metal objects. These patterns often resemble flowing water, wood grain, or intricate geometric shapes. Pattern-welded items are highly valued for their artistic and decorative qualities.

- Structural Strength: Beyond its visual appeal, pattern welding also enhances the mechanical properties of the material. By combining different metals with varying hardness, ductility, and toughness, pattern-welded objects can possess superior strength and durability compared to single-metal counterparts. This makes them well-suited for tools, weapons, and other functional items.

- Cultural and Historical Significance: Pattern welding holds cultural and historical significance as it was used in the production of legendary weapons such as Viking swords, Celtic blades, and Japanese katana. These weapons were revered for their superior performance and became symbols of power, craftsmanship, and heritage.

Materials Used in Pattern Welding

Materials Used Pattern welding typically involves the use of ferrous metals, especially those with high carbon content, due to their forgeability and ability to create contrasting patterns. The primary metals used in pattern welding include:

- Iron: The base metal often used for pattern welding due to its abundance and workability. It provides a strong foundation for layering other metals.

- Carbon Steel: High-carbon steels, such as W1 and W2, are commonly incorporated into pattern welding. These steels contribute to the formation of distinctive patterns and provide hardness and edge retention to the final product.

- Nickel: Nickel is often used as a contrasting metal due to its bright silver color. It forms distinct lines or bands in the pattern, creating a striking visual contrast with the darker materials.

- Non-ferrous Metals: Some pattern-welded items may incorporate non-ferrous metals like copper, bronze, or brass to add further visual interest and variety to the patterns.

The combination and layering of these different metals during the forging process give rise to the unique and captivating patterns associated with pattern welding.

Basics of Pattern Welding

Types of Materials

- Ferrous and Non-ferrous Metals: Pattern welding primarily involves the use of ferrous metals, which contain iron as their primary component. However, non-ferrous metals like copper, bronze, and brass may also be incorporated for visual interest and contrast within the patterns.

- Carbon Content and Properties: Carbon content plays a crucial role in pattern welding. High-carbon steels, such as W1 and W2, are often used to create distinctive patterns. These steels offer hardness, edge retention, and the ability to develop contrast when etched. Lower carbon steels are used as a base or filler material, providing strength and stability to the overall structure.

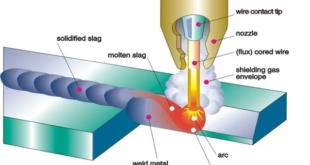

Forge Welding Techniques

- Heating and Joining the Materials: The first step in pattern welding is heating the metal pieces to their forging temperature. This can be done in a traditional coal or gas forge, or with modern induction or gas forges. Once heated, the materials are carefully aligned and placed in contact to create a solid bond during the welding process.

- Hammering and Shaping: With the materials joined together, the blacksmith uses hammers and other shaping tools to forge the welded billet into the desired shape. This involves precise strikes and controlled deformation to ensure the layers remain intact while achieving the desired form, be it a blade, bar, or other object.

Layering and Folding

- Creating Multiple Layers: Layering is a fundamental aspect of pattern welding. The blacksmith arranges multiple thin sheets or strips of different metals on top of each other to form a stack. The choice and order of metals influence the final pattern. The layered stack is then welded together, creating a solid composite material.

- Folding to Increase Layer Count: After initial welding, the layered stack is often folded to increase the number of layers and enhance the complexity of the pattern. The blacksmith carefully heats the stack, hammers it flat, and then folds it over onto itself. This process can be repeated multiple times to achieve a higher layer count and more intricate patterns.

Drawn Out and Twisted Patterns

- Pulling the Material to Create Elongated Shapes: To create elongated patterns, the blacksmith may draw out sections of the layered stack. This involves heating a specific area and then using tongs or other tools to carefully stretch and thin out the material. The elongated section can be twisted or further manipulated to enhance the pattern.

- Twisting for Decorative Effects: Twisting is a technique used to create visually captivating patterns. The blacksmith heats a section of the layered stack and, while it is malleable, twists it using tongs or vise grips. This twisting action causes the layers to rotate and intermingle, resulting in unique and striking patterns when the metal is forged and etched.

Types of Pattern Welding

Solid Core Pattern Welding

- Creating a Solid Core with Patterned Edges: In solid core pattern welding, the primary focus is on the central core of the object, while the edges are adorned with intricate patterns. This technique involves forging a solid core from a single type of metal, often high-carbon steel, and then adding layers of contrasting metals to the outer edges. The contrasting layers are manipulated and forged to create visually appealing patterns.

- Examples of Designs and Techniques:

- Twist Core: A twisted pattern is created within the solid core, while the outer edges feature contrasting patterns.

- Chevron Core: The solid core is formed into a chevron pattern, while the edges display different patterns, such as ladder or raindrop.

- Feather Core: The solid core is manipulated to resemble feathers, while the surrounding layers showcase various patterns like a ladder or serpent.

Twist Pattern Welding

- Twisting Multiple Layers for Unique Patterns: Twist pattern welding involves twisting the entire layered stack to create captivating spiral patterns throughout the material. This technique results in continuous twists that extend from one end of the object to the other, producing a visually striking effect.

- Variations and Examples:

- Single Twist: The layered stack is twisted in one direction, creating a single spiral pattern throughout the material.

- Double Twist: The layered stack is twisted in one direction, then twisted again in the opposite direction, resulting in a double spiral pattern.

- Cable Twist: Multiple twisted stacks are combined and twisted together, resembling the appearance of cables.

Composite Pattern Welding

- Combining Different Materials for Contrast: Composite pattern welding involves incorporating distinct metals with varying colors and properties into the layered stack. By combining metals like high carbon steel, nickel, and non-ferrous alloys, striking visual contrasts and patterns are achieved.

- Layering Techniques and Examples:

- Random Layering: Different metals are layered randomly, resulting in a varied and irregular pattern when forged and etched.

- Sandwiched Layers: Multiple layers of contrasting metals are alternated, creating distinct bands or lines in the final pattern.

- Checkerboard Pattern: Layers of different metals are arranged in a checkerboard-like pattern, forming a visually appealing grid design.

Mosaic Pattern Welding

- Intricate Patterns Created with Layered Materials: Mosaic pattern welding involves meticulously arranging and manipulating small sections of layered metals to form intricate and detailed patterns. These patterns can resemble flowers, animals, geometric shapes, or elaborate scenes.

- Techniques and Examples:

- Tessellation: Small geometric shapes, such as triangles or diamonds, are repeated and interlocked to create a mosaic-like pattern.

- Scene Depiction: Layered metals are carefully shaped and manipulated to depict scenes or figures, similar to a mosaic artwork.

- Micro-Mosaic: Extremely small sections of layered metals are arranged to create intricate designs and detailed imagery.

These different types of pattern welding techniques allow for a wide range of artistic expressions and variations, enabling blacksmiths to create unique and captivating patterns in their work.

Tools and Equipment

Forge and Heating Methods

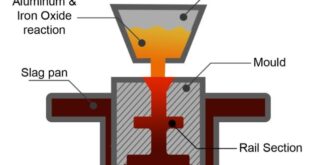

- Traditional Coal or Gas Forges: Traditional coal forges utilize a coal fire as a heat source, providing a steady and controllable temperature for forging. Gas forges, on the other hand, use propane or natural gas to generate heat. Both types of forges require proper ventilation and a fire management system to maintain the desired temperature.

- Modern Induction or Gas Forges: Modern induction forges use electromagnetic fields to generate heat directly in the metal, offering precise and efficient heating. Gas forges, similar to traditional ones, utilize gas burners for heat generation. Induction and gas forges are often preferred for their convenience, control, and energy efficiency.

Anvils, Hammers, and Tongs

- Types and Uses of Different Hammer Shapes:

- Cross Peen Hammer: Featuring a flat face on one end and a wedge-shaped cross peen on the other, this hammer is used for general forging and shaping tasks.

- Ball Peen Hammer: Similar to a cross peen hammer, but with a rounded peen. It is used for riveting, texturing, and shaping metal.

- Rounding Hammer: With rounded faces on both ends, this hammer is suitable for drawing out and shaping metal.

- Flatter Hammer: Featuring a wide and flat face, it is used for flattening and smoothing metal surfaces.

- Holding and Manipulating the Workpiece with Tongs: Tongs are essential tools for securely holding and manipulating hot metal during forging. Different types of tongs are designed for specific purposes, such as flat jaw tongs for general use, scrolling tongs for creating scrolls, and wolf jaw tongs for gripping irregularly shaped objects.

Grinding and Polishing Equipment

- Removing Scale and Imperfections:

- Angle Grinder: Equipped with abrasive grinding discs, an angle grinder is commonly used to remove scale, excess material, and surface imperfections.

- Belt Sander: Utilizing continuous abrasive belts, a belt sander is effective for shaping, smoothing, and refining the surface of pattern-welded objects.

- Achieving a Polished Finish:

- Polishing Wheels: Various types of polishing wheels, such as cloth, felt, or sisal wheels, are used in combination with polishing compounds to achieve a smooth and lustrous finish.

- Buffing Wheel: A soft, cotton or flannel wheel, often used in conjunction with polishing compounds, for final polishing and buffing to enhance the shine of the pattern-welded item.

Applications of Pattern Welding

Historical Artifacts and Weapons

- Viking and Celtic Swords: Pattern-welded swords were highly prized by the Vikings and Celts for their exceptional strength, flexibility, and aesthetic appeal. These swords often featured intricate patterns on their blades, such as ladder, twist, or serpent patterns.

- Japanese Katana and Wakizashi: The art of pattern welding is integral to the creation of Japanese swords, including the iconic katana and wakizashi. The traditional method of steel production in Japan, known as “Tamahagane,” involves folding and layering carbon-rich and low-carbon steels to achieve a distinctive grain pattern called “Hada.”

Modern Artistic and Decorative Items

- Knives, Jewelry, and Sculptures: Pattern welding has found its place in contemporary craftsmanship, where it is utilized to create unique and visually stunning knives, jewelry pieces, and sculptures. Knives with pattern-welded blades exhibit beautiful patterns that enhance their aesthetic appeal and can be functional tools or collector’s items. Jewelry items, such as rings, pendants, and bracelets, often incorporate pattern-welded elements, adding a touch of elegance and individuality. Pattern-welded steel is also employed in the creation of sculptures, where it serves as a medium for artistic expression.

- Custom Designs and Commissions: The versatility of pattern welding allows artisans to create custom designs tailored to the specific preferences of their clients. From personalized knives and jewelry to larger-scale projects like architectural elements and furniture, pattern welding offers the opportunity to produce one-of-a-kind pieces that reflect the client’s vision and taste.

Safety Considerations

Protective Clothing and Equipment

- Heat-Resistant Clothing: When working with hot metals and in a forge environment, wearing heat-resistant clothing, such as leather aprons and gloves, is crucial to protect against burns and sparks.

- Eye Protection: Safety glasses or goggles should be worn to shield the eyes from flying debris, hot sparks, and potential hazards during the forging and grinding processes.

- Hearing Protection: Prolonged exposure to loud hammering and power tools can damage hearing. Wearing earplugs or earmuffs is recommended to minimize the risk of hearing loss.

- Respiratory Protection: In situations where there is significant smoke, fumes, or particulate matter, using a properly fitted respirator or dust mask helps prevent inhalation of harmful substances.

Fire and Heat Safety

- Proper Ventilation: Ensure the forge area has adequate ventilation to remove smoke, fumes, and gases generated during the forging process. This helps maintain breathable air and reduces the risk of exposure to harmful substances.

- Fire Safety: Keep a fire extinguisher nearby and familiarize yourself with its usage. Regularly inspect and maintain all heating equipment to prevent potential fire hazards.

- Heat Management: Exercise caution when working with hot materials and tools. Use insulated gloves or tongs to handle hot objects, and avoid contact with bare skin to prevent burns.

Hammering and Handling Precautions

- Stable Work Surface: Ensure your work surface is stable and securely fixed to prevent accidental movement or toppling during hammering.

- Proper Tool Use: Use tools, such as hammers, anvils, and tongs, appropriately and in accordance with their intended purpose. Misuse or improper handling can lead to accidents or injuries.

- Controlled Hammer Strikes: Practice controlled and precise hammering techniques to minimize the risk of accidental slips or injuries. Maintain a stable grip on the hammer and maintain proper body mechanics to prevent strain or repetitive stress injuries.

Adhering to safety practices and utilizing the appropriate protective clothing and equipment are essential for ensuring a safe working environment when engaging in pattern welding. By prioritizing safety, artisans can enjoy their craft while minimizing the risk of accidents or injuries.

FAQs

What is the pattern welding process?

Pattern welding is a process used to forge and create a composite steel material with distinctive patterns. It involves layering and manipulating different types of metals, typically high-carbon and low-carbon steels, to achieve desired visual effects and enhance the strength and performance of the resulting material. The layered stack is heated, forged, and repeatedly folded to create a cohesive billet or bar of pattern-welded steel.

Is pattern welding the same as Damascus?

Yes, pattern welding is often referred to as Damascus steel. The terms “pattern welding” and “Damascus” are used interchangeably to describe the process and resulting material. However, it is important to note that the modern pattern-welded steel produced today is not identical to the historical Damascus steel of ancient times, which had unique properties due to the specific iron ores and forging techniques used in its production.

How is pattern-welded steel made?

Pattern-welded steel is made by layering and forge-welding different types of steel together. The process typically involves the following steps:

- Selecting and preparing the steel: High-carbon and low-carbon steels with contrasting properties are chosen for layering.

- Layering: The steels are stacked in alternating layers to create a billet or bar, with the desired pattern in mind.

- Forge welding: The stacked billet is heated in a forge and brought to welding temperature. It is then hammered or pressed to forge the layers together, creating a solid and cohesive piece.

- Repeating the process: The billet is repeatedly heated, forged, and folded to increase the layer count and develop the desired pattern.

- Final shaping and finishing: The pattern-welded bar is shaped and refined through grinding, polishing, and other techniques to reveal intricate patterns and achieve the desired finish.

What is pattern steel?

Pattern steel refers to the result of the pattern welding process, where different layers of steel are forged together to create a composite material with distinct patterns visible on the surface. The patterns are achieved by manipulating and folding the layers of steel during the forging process. Pattern steel is highly valued for its aesthetic appeal and can be used to create blades, decorative items, and other objects.

What is the strongest welding pattern?

The strength of a welding pattern depends on several factors, including the types of steels used, the quality of the forge welding, and the overall construction of the welded piece. While certain patterns may exhibit specific characteristics, it is difficult to determine a single pattern as the “strongest” overall. The strength of a pattern-welded piece is primarily determined by the quality of the materials used and the craftsmanship in the forging and heat treatment processes.

What are the 5 steps in welding?

The five general steps in welding, often referred to as the welding process, are as follows:

- Preparation: This involves cleaning and preparing the base metals to be welded, ensuring they are free of contaminants and properly aligned for welding.

- Tacking: The pieces to be welded are temporarily positioned and secured using tack welds to hold them in place during the welding process.

- Welding: The actual joining of the base metals takes place, where heat is applied to melt the edges or surfaces, and a filler material may be added to create a strong bond.

- Inspection: After welding, the joint is inspected visually or using non-destructive testing methods to determine the quality and integrity of the weld. This step is crucial for ensuring that the weld meets the required specifications and standards.

- Finishing: Once the weld has passed inspection, any excess material or rough edges are removed, and the weld area is cleaned and smoothed to achieve the desired final appearance.

Can you pattern weld iron?

Pattern welding is typically performed using steels that have different carbon contents, such as high-carbon and low-carbon steels. Iron itself, being a relatively low-carbon material, is not commonly used in pattern welding due to its limited carbon content. The process of pattern welding relies on the contrast in carbon content between the different layers of steel to create the desired patterns. However, iron can be combined with steel in the layering process to achieve specific design effects or to introduce contrast within the pattern-welded piece.

Why was Damascus steel lost?

The true production methods and techniques of ancient Damascus steel, which was highly prized for its exceptional quality and performance, were lost to history. The knowledge and understanding of the specific processes, materials, and techniques used to create Damascus steel have been lost over time. Various theories suggest that factors such as changes in the availability of raw materials, the decline of the original Damascus steel production centers, and the secrecy surrounding the techniques contributed to the loss of this ancient art. Modern attempts to replicate the properties of historical Damascus steel have focused on the visual patterns rather than precisely recreating the metallurgical properties.

How many layers is Damascus steel?

The number of layers in Damascus steel can vary depending on the preferences and techniques of the bladesmith or blacksmith. Traditionally, Damascus steel blades were made using a combination of high-carbon and low-carbon steel layers, which were folded and welded repeatedly to increase the layer count and refine the pattern. The layer count could range from a few dozen to several hundred layers, resulting in the intricate and visually appealing patterns seen in Damascus steel.

Why is it called Damascus pattern?

The term “Damascus” is derived from the name of the city of Damascus in present-day Syria. Damascus steel was highly regarded and sought after during medieval times, and its production was associated with the city of Damascus. The name “Damascus” became synonymous with the distinctive pattern and exceptional quality of the steel. The patterns seen in pattern-welded steel are reminiscent of the historical Damascus steel, which led to the term “Damascus pattern” being used to describe the intricate patterns achieved through the pattern welding process.

Conclusion

Throughout this overview, we have explored the fundamentals of pattern welding, including the basics of materials, forge welding techniques, layering and folding, as well as drawn-out and twisted patterns. We have also delved into the various types of pattern welding, such as solid core, twist, composite, and mosaic, each offering its own unique visual characteristics and challenges. Pattern welding holds significant historical and artistic importance. It has been utilized for centuries in the production of renowned weapons, such as Viking swords and Japanese katana, showcasing both the craftsmanship and functional superiority of pattern-welded blades. In modern times, pattern welding continues to thrive as an artistic expression, with its application expanding to decorative items, sculptures, and custom designs. The enduring legacy of pattern welding lies in its ability to merge craftsmanship, tradition, and creativity into functional and aesthetically captivating objects.

For those interested in diving deeper into the world of pattern welding, there are various resources available for inspiration and knowledge expansion. These include:

- Books: Explore books on blacksmithing, bladesmithing, and historical weapon production, which often feature sections dedicated to pattern welding techniques.

- Workshops and Classes: Attend workshops or take classes offered by experienced blacksmiths and bladesmiths specializing in pattern welding. Hands-on learning and guidance can provide valuable insights and skills.

- Online Communities and Forums: Engage with online communities, forums, and social media groups dedicated to blacksmithing and bladesmithing. These platforms offer opportunities to connect with fellow enthusiasts, share knowledge, and seek advice.

Pattern welding is not only a craft deeply rooted in history but also a living art form that continues to evolve and inspire. By embracing the techniques, exploring its historical significance, and tapping into the wealth of resources available, individuals can embark on their own creative journey in the realm of pattern welding.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders