Lack of Fusion in Welded Joints

Welding is a fundamental process in various industries, from construction to manufacturing. It involves joining metal pieces together using high heat to melt the base metals and then allowing them to cool and solidify, forming a strong bond. However, one of the challenges welders face is ensuring proper fusion throughout the weld joint. Lack of fusion occurs when there is an insufficient bond between the molten weld metal and the base metal, leading to weak or incomplete welds.

Understanding Lack of Fusion

Lack of fusion, as the name suggests, refers to the failure of molten weld metal to fuse adequately with the base metal or previously deposited weld metal. This results in discontinuities within the weld joint, compromising its structural integrity. Proper fusion is crucial for ensuring the strength and reliability of welded components, as any deficiency in fusion can lead to defects and failures under stress.

Causes of Lack of Fusion

Several factors can contribute to lack of fusion in welded joints:

1. Inadequate Heat Input

Insufficient heat during the welding process can prevent proper melting of the base metals, resulting in incomplete fusion. This can occur due to incorrect welding parameters or inadequate power sources.

2. Poor Welder Technique

Lack of skill or experience in welding techniques can lead to improper manipulation of the welding equipment, resulting in inadequate fusion between the metal surfaces.

3. Contamination of Welding Surfaces

Presence of contaminants such as dirt, rust, or oil on the welding surfaces can inhibit proper fusion by creating barriers between the molten weld metal and the base metal.

Impact of Lack of Fusion

The consequences of lack of fusion in welded joints can be severe:

Structural Integrity Compromise

Weak or incomplete welds due to lack of fusion compromise the structural integrity of welded components, making them susceptible to premature failure under load or stress.

Increased Susceptibility to Defects and Failures

Welds with insufficient fusion are more prone to defects such as cracks, porosity, and lack of penetration, increasing the risk of component failure over time.

Detecting Lack of Fusion

Detecting lack of fusion is essential for ensuring the quality of welded joints:

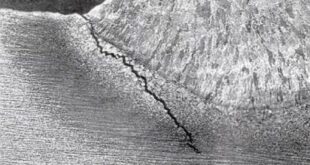

Visual Inspection

Visual examination of the weld bead can reveal signs of incomplete fusion, such as unfilled grooves or lack of penetration into the base metal.

Non-Destructive Testing Methods

Techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing can be used to identify lack of fusion defects without damaging the welded component.

Preventing Lack of Fusion

Preventive measures can help minimize the occurrence of lack of fusion:

Proper Welding Parameters

Ensuring that the welding process parameters, such as heat input, travel speed, and electrode selection, are optimized for the specific materials being welded can promote adequate fusion.

Surface Preparation Techniques

Thorough cleaning and preparation of welding surfaces to remove contaminants and ensure proper fit-up are essential for achieving good fusion in welded joints.

Quality Control Measures

Implementing rigorous quality control procedures, including welder qualification tests and inspection protocols, can help identify and rectify lack of fusion issues before they compromise the integrity of welded structures.

FAQs

What are the common causes of lack of fusion in welded joints?

Common causes include inadequate heat input, poor welder technique, and contamination of welding surfaces.

How can lack of fusion impact the structural integrity of welded components?

Lack of fusion can compromise structural integrity, making welded components susceptible to defects and failures under stress.

What are some preventive measures for addressing lack of fusion?

Preventive measures include optimizing welding parameters, thorough surface preparation, and implementing quality control measures.

Why is proper training and education important in reducing lack of fusion issues?

Proper training improves welder skills and awareness, leading to better adherence to welding best practices and standards.

What are some future trends in welding technology aimed at addressing lack of fusion?

Advancements in welding technology focus on improving processes, materials, and equipment design to minimize lack of fusion defects and enhance weld quality.

Conclusion

In conclusion, lack of fusion poses significant challenges to the integrity and reliability of welded joints. By understanding the causes, impacts, detection methods, and preventive measures associated with lack of fusion, welders can take proactive steps to ensure high-quality welds that meet safety and performance standards.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders