Safe Welding around Water and in Rain

Welding is a critical process used in various industries, and it’s essential to carry out this task with safety as a top priority. However, welding in wet conditions, such as around water or in rainy weather, introduces additional challenges and risks.

Introduction

Welding is a crucial process used to join metals permanently. However, when it comes to welding in wet or rainy conditions, there are additional risks that welders need to be aware of. This article aims to provide insights into the necessary precautions and best practices for ensuring safety while welding in these challenging environments.

Understanding the Risks

Electrical Hazards

One of the significant risks of welding in wet conditions is the potential for electrical hazards. Water is an excellent conductor of electricity, and when it comes into contact with welding equipment or the workpiece, the risk of electric shock increases significantly.

Hydrogen Gas Formation

During the welding process, water can be vaporized, leading to the release of hydrogen gas. The accumulation of hydrogen in the welding area can create an explosive atmosphere, posing a severe safety hazard.

Electrode Sticking

In wet conditions, electrodes can become damp or wet, leading to issues like electrode sticking. This can affect the weld quality and may result in incomplete welds or defects.

Reduced Visibility

Rain and water splatter can obscure the welder’s vision, making it difficult to see the welding arc and the joint being welded, increasing the likelihood of errors.

Safety Precautions

To ensure safe welding in wet conditions, welders must take specific precautions to mitigate the risks involved.

Weather Monitoring

Before starting any welding activity, it’s essential to check the weather forecast. Avoid welding if heavy rain or thunderstorms are predicted.

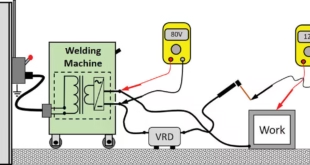

Proper Grounding

Proper grounding is crucial to prevent electrical hazards. Ensure that all welding equipment and power sources are adequately grounded.

Insulation and Isolation

To avoid electric shock, the welding area should be dry, and welders must stand on insulated and dry surfaces.

Personal Protective Equipment (PPE)

Welders should wear appropriate PPE, including insulated gloves and boots, to protect against electrical shocks and dampness.

Suitable Welding Processes for Wet Conditions

Certain welding processes are better suited for wet environments due to their ability to handle moisture and produce quality welds.

Shielded Metal Arc Welding (SMAW)

SMAW, also known as stick welding, is relatively tolerant of damp conditions and can be used effectively in light rain.

Gas Metal Arc Welding (GMAW/MIG)

GMAW, or MIG welding, can be suitable for wet conditions when using the proper shielding gases and wires.

Flux-Cored Arc Welding (FCAW)

FCAW provides better control over the welding process in windy and wet conditions due to its flux-filled electrode.

Avoiding Moisture Contamination in Welding Materials

Moisture can also affect the quality of welding materials, leading to weld defects and reduced strength.

Storage and Handling

Store welding consumables in dry conditions and avoid leaving them exposed to rain or moisture.

Preheating

Preheating the base metal can help drive out any moisture, ensuring better weld quality.

Drying Techniques

Consider using ovens or specialized drying equipment to remove moisture from welding materials.

Working with Welding Machines and Power Sources

Electrical safety is critical when welding in wet conditions, and precautions must be taken to protect both the welder and the equipment.

Ground-Fault Circuit Interrupters (GFCIs)

Using GFCIs can provide an additional layer of safety by detecting and interrupting electrical faults.

Elevated Platforms and Dry Platforms

Welders should work on elevated platforms or dry surfaces to reduce the risk of electrical shock.

Proper Machine Maintenance

Regularly inspect and maintain welding machines to ensure they are in proper working condition.

Maintaining Visibility and Clarity

Maintaining clear visibility is essential for producing quality welds in wet conditions.

Welding Helmets with Auto-Darkening Filters

Auto-darkening helmets help welders maintain visibility by automatically adjusting the lens shade.

Clearing Water from the Work Area

Use squeegees or other tools to clear water from the welding area to improve visibility.

Adequate Lighting

Ensure there is sufficient lighting to compensate for reduced visibility caused by rain or water splatter.

Welding in Wet and Water-Submerged Conditions

In some cases, welding may be required in fully submerged or underwater environments.

Underwater Welding Techniques

Specialized welding techniques and equipment are used for underwater welding, such as dry chambers and wet welding.

Dry Chambers and Enclosures

Dry chambers and enclosures create a controlled environment for underwater welding, ensuring safety and quality.

Post-Welding Precautions and Inspections

After completing the welds in wet conditions, additional precautions and inspections are necessary.

Cleaning and Drying Welded Surfaces

Thoroughly clean and dry the welded surfaces to prevent corrosion.

Non-Destructive Testing (NDT)

Consider using NDT methods to check for hidden defects and ensure weld integrity.

Monitoring for Corrosion

Regularly monitor welded structures for signs of corrosion, as wet conditions can accelerate this process.

Best Practices for Welding in Rainy Weather

When welding in rainy weather, specific best practices can enhance safety and efficiency.

Portable Shelters

Use portable shelters or tarps to protect the welding area from rain.

Rain Protection Gear

Welders should wear appropriate rain protection gear to stay dry and comfortable.

Drying Stations

Set up drying stations for welding materials and equipment to prevent moisture contamination.

Conclusion

Safe welding around water and in rainy weather requires a comprehensive understanding of the risks involved and the necessary precautions to mitigate them. Welders must prioritize electrical safety, moisture control, and visibility to produce high-quality welds and ensure their well-being. By following the guidelines and best practices outlined in this article, welding professionals can confidently tackle welding projects even in challenging wet conditions.

FAQs

Is welding in the rain dangerous?

Welding in the rain can be hazardous due to the increased risk of electrical shocks and reduced visibility.

Can I use any welding process in wet conditions?

Certain welding processes, such as SMAW, GMAW/MIG, and FCAW, are more suitable for wet conditions than others.

How do I protect myself from electric shocks while welding near water?

Proper grounding, insulation, and using personal protective equipment can help protect against electric shocks.

What should I do if my welding materials get wet?

Store welding materials properly, preheat them if necessary, and use drying techniques to remove moisture.

What are the best practices for welding in rainy weather?

Using portable shelters, rain protection gear, and drying stations can enhance safety and efficiency while welding in the rain.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders